BA_PH_436-100_EN_44-21.docx

45

15.5

Rubber Roller Replacement

Preparation:

•

Plane a piece of squared timber with min. 150 mm on the right side of the thicknessing table

(length approx. 1.5 m).

•

Then stop the feed; the workpiece must rest under the infeed and outfeed roller as support.

Switch off the machine, turn off the main switch and lock it!

Switch off the machine during maintenance and repair work and secure it against being

switched on again unexpectedly! Lock the main switch with a padlock!

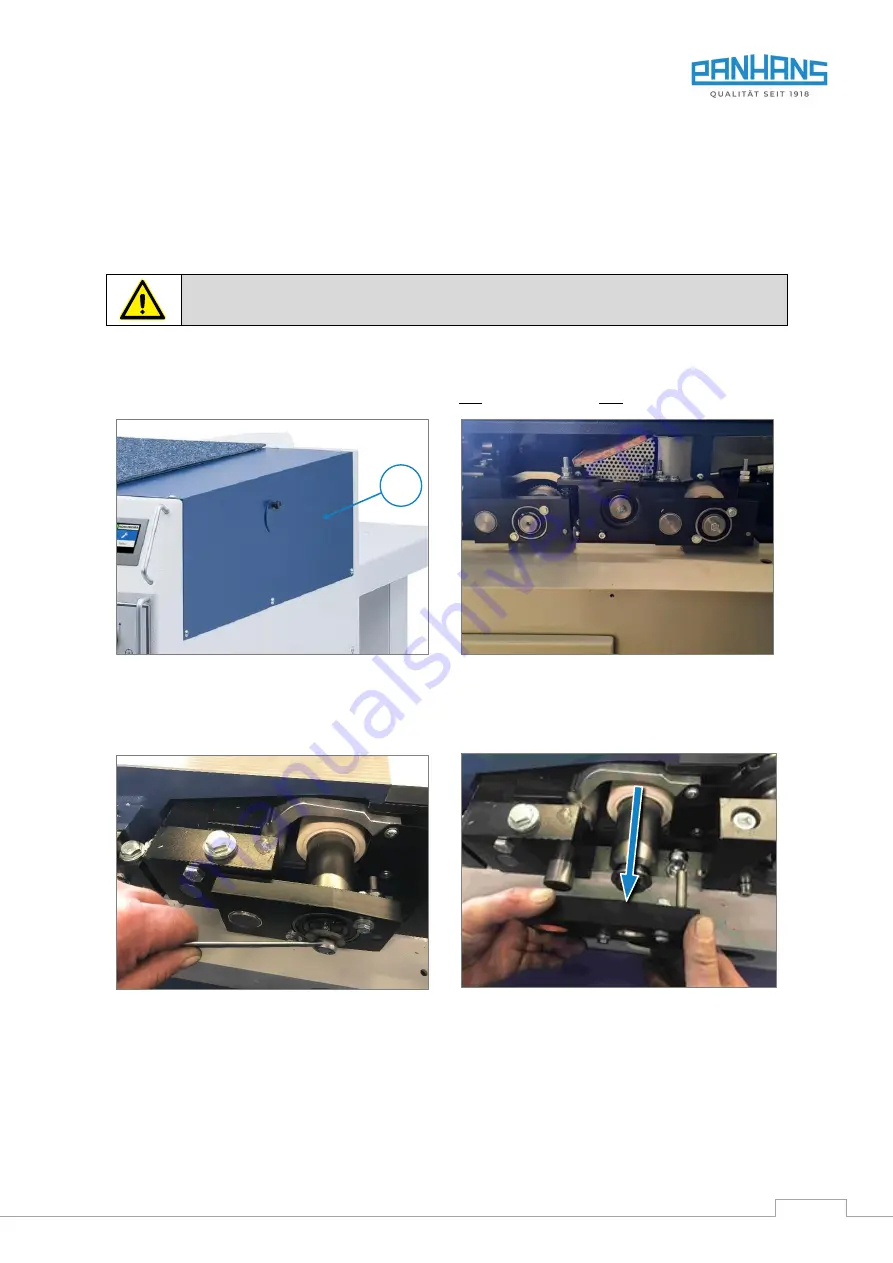

Step 1

To make the rollers accessible, first remove the side

cover (

A

) and place it on the top of the machine.

The rollers are now visible:

Left

→

infeed roller / Right

→

outfeed roller

Figure 53: Rubber roller replacement Step 1a

Figure 54: Rubber roller replacement Step 1b

Step 2

Step 3

On the pendulum bearing of the feed roller, loosen

the M8 screw with a SW13 spanner:

Pull off the pendulum bearing to the front, remove

the sleeve and shim washer:

Figure 55: Rubber roller replacement Step 2

Figure 56: Rubber roller replacement Step 3

Step 4

Pull out the rubber segments from the main shaft to the front. Let segments 2 - 5 (by hand and preferably with

the help of a second person) be pushed above the thicknessing table. For this purpose the prepared squared

timber with min. 150 mm thickness serves. Now push the new segments onto the shaft.

A