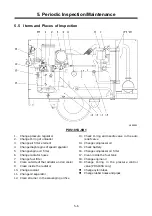

5. Periodic Inspection/Maintenance

5

-

2

Precautions for check and maintenance

Be sure to use recommended fuel, oil, grease, and antifreeze.

Do not disassemble or adjust engine, compressor or part(s) for which inspection or maintenance is not

referred to in this manual.

Use genuine parts for replacement.

Any breakdown, caused by using unapproved parts or by wrong handling, will be out of the scope of

“WARRANTY”.

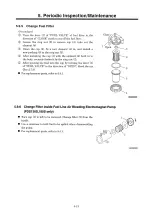

Keep the electrical components away from water or steam.

Waste from machines contains harmful material. Do not dispose of such harmful fluids to the ground,

rivers, lakes or ponds, and sea. It contaminates the environment.

When draining waste fluid from machines, use leakproof containers to hold such fluids from machine.

Be sure to follow the designated regulations when disposing of oil, fuel, coolant, filters, battery and other

harmful things.

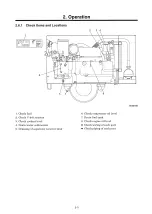

5.2 Daily Inspection and Operation Log

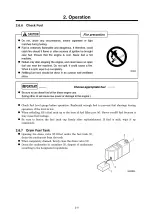

Be sure to carry out daily inspection every morning before operation. See Chapter 2 “Operation” of

the manual for the details of inspection.

Pay attention to and carefully observe the following points during daily operation or inspection and

maintenance work. If any trouble or abnormality is found, immediately investigate its cause and

make repairs. If the cause is unknown or not traceable, or if the trouble involves a part or

component not described in the manual, ask your nearest dealer for information.

(a)Controls and instruments function properly.

(b)Quantity and any leak of water, fuel, and oil or any

contamination should be checked.

(c)Appearance, abnormal noise or excessive heat should be

checked.

(d)Loose bolt or nut should be checked.

(e)Any damage, wear or shortage of machine components and

parts should be checked.

(f)Performance of each part or component should be proper.

Keep the operation log to record constant inspection of each component, so that trouble of the unit

can be easily discovered and preventive measures can be taken.

It is very useful to record information such as discharge pressure, oil level, as well as running hour,

maintenance items and replenishment of lubricant on a daily maintenance log.

TR0049

Summary of Contents for Airman PDS100S-6B1

Page 1: ......

Page 2: ......

Page 4: ......

Page 5: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 38: ......

Page 40: ......

Page 42: ......

Page 44: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ...9 Wiring Diagram 9 1 A040035...

Page 60: ...10 Piping Diagram 10 1 PDS100S 6B1 A050211...

Page 61: ...10 Piping Diagram 10 2 PDS130S 6B1 A050202E...

Page 62: ...10 Piping Diagram 10 3 PDS185S 6B1 A050204E...

Page 64: ......