5. Periodic Inspection/Maintenance

5

-

6

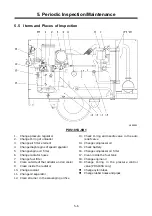

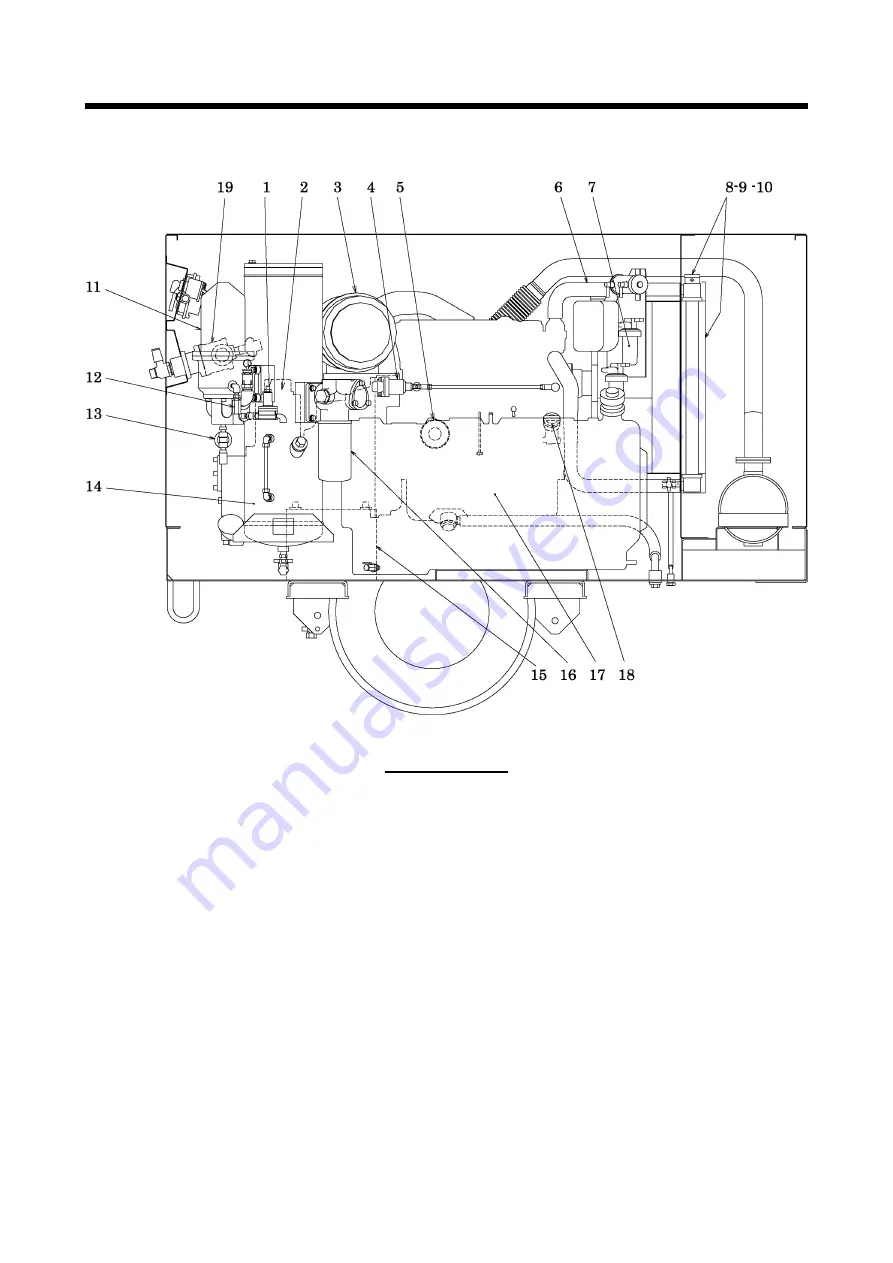

5.5 Items and Places of Inspection

A000083

PDS185S-6B1

1. Change pressure regulator

2. Change O-ring of unloader

3. Change air filter element

4. Change diaphragms of speed regulator

5. Change engine oil filter

6. Change radiator hoses

7. Change fuel filter

8. Clean outside of the radiator and oil cooler

9. Clean inside the radiator

10. Change coolant

11. Change oil separator

12. Clean strainer in the scavenging orifice

13. Check O-ring and needle valve in the auto

relief valve

14. Change compressor oil

15. Check battery

16. Change compressor oil filter

17. Clean inside the fuel tank

18. Change engine oil

19. Change O-ring in the pressure control

valve (PDS185S only)

Change nylon tubes

Change rubber hoses and pipes

Summary of Contents for Airman PDS100S-6B1

Page 1: ......

Page 2: ......

Page 4: ......

Page 5: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 38: ......

Page 40: ......

Page 42: ......

Page 44: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ...9 Wiring Diagram 9 1 A040035...

Page 60: ...10 Piping Diagram 10 1 PDS100S 6B1 A050211...

Page 61: ...10 Piping Diagram 10 2 PDS130S 6B1 A050202E...

Page 62: ...10 Piping Diagram 10 3 PDS185S 6B1 A050204E...

Page 64: ......