HMPRO50 OPERATOR’S MANUAL

www.holemaker.com

5

GROUNDING INSTRUCTIONS

POWER SUPPLY REQUIREMENTS

WARNING!

Improperly connecting the grounding wire can result in the risk of electrical shock.

Prior to use check condition of the power cord, which has to be free of any cuts, or similar damages.

Attention!: This unit has a class one of insulation and

absolutely requires the power source

to be equipped with a protection circuit.

Power source should be protected with the difference-current circuit cut-out and protected with a 10A fuse - for 230V.

At building sites, power should be supplied from a separation transformer such as Type AVM, with minimum power of

2000 VA and with second class protection.

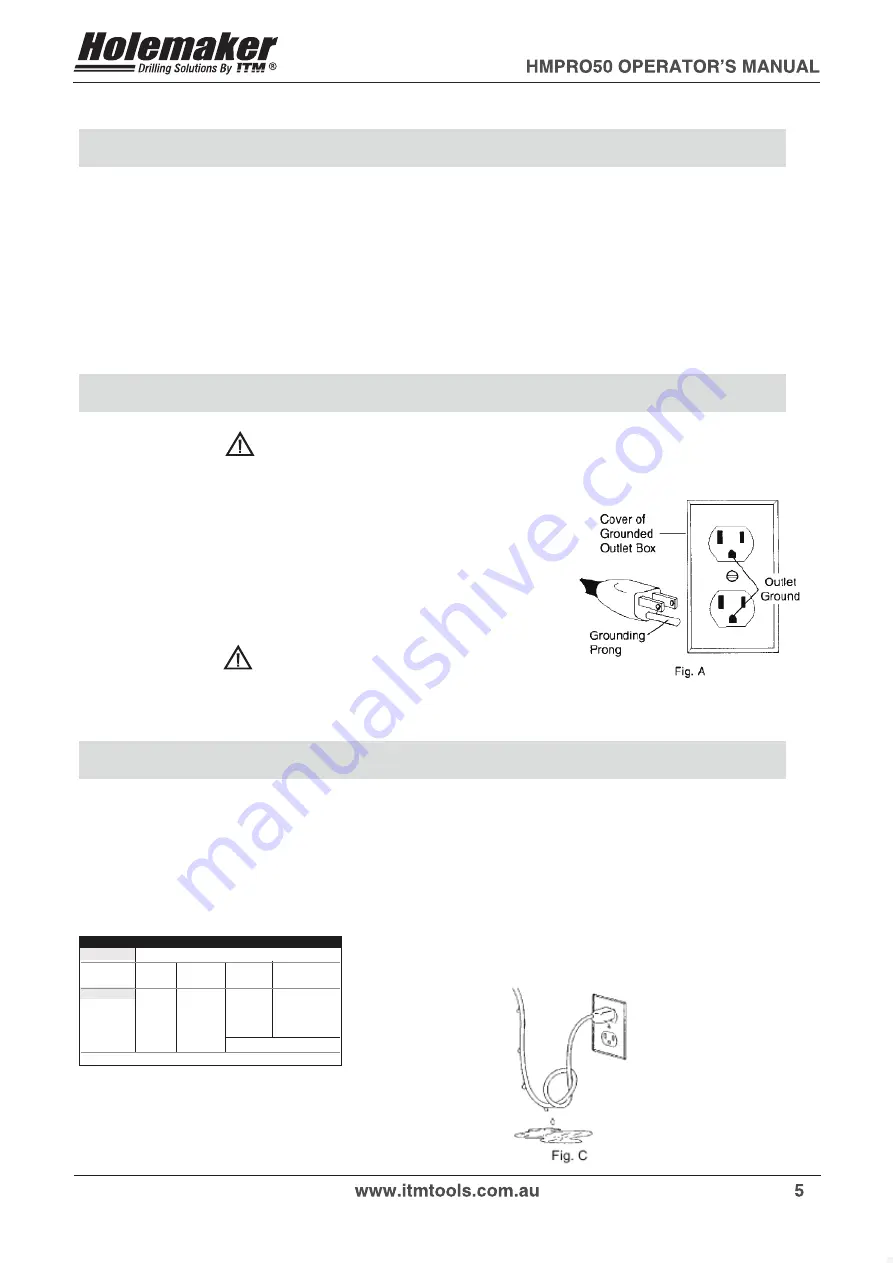

Check with a qualified electrician if you are in doubt as to whether the outlet

is properly grounded. Do not modify the plug provided with tool. Never remove

the grounding prong from the plug. If the cord or plug is damaged, have it

repaired before using. If the plug will not fit the outlet, have a proper outlet

installed by a qualified electrician. The Holemaker must be plugged into an

appropriate outlet, properly installed and grounded in accordance with all codes

and ordinances. The plug and outlet should look similar to those in Figure A.

If in doubt of proper grounding, call a qualified electrician.

WARNING!

DO NOT USE HOLEMAKER DRILLING MACHINES ON SURFACES OR MATERIALS BEING

WELDED

.

DOING SO CAN RESULT IN DAMAGE TO THE DRILLING MACHINE.

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole receptacles that accept the

tool’s plug. Replace or repair damaged cords. Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of power and overheating. See table for the correct size to use

depending on cord length and nameplate amperage rating. If in doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

12-16

VOL TS

240V

AMPERAGE

0-6

6-10

10-12

14

RECOMMENDED WIRE GAUGE

12

MINIMUM GAUGE FOR EXTENSION CORDS

TOTAL LENGTH OF CORD IN METRES

0 - 15

15 - 30

30 - 60

60 - 90

18 16 16 14

18 16 14 12

16 16 14 12

NOT RECOMMENDED

DRIP LOOP: To help prevent cutting fluids from traveling

along power cord and contacting power source, tie a drip

loop in power cord as shown in Figure C.

5

Summary of Contents for HMPRO50

Page 21: ...HMPRO50 OPERATOR S MANUAL www holemaker com 21 21 ...

Page 22: ......