User Manual

Version 1.0 15

VIII. Troubleshooting

IX.

Maintenance and Cleaning

Keep the instrument dry and clean in routine operations.

Clean the outer surface with a non-abrasive cleanser and only connect the power supply

when the entire instrument surface is dry.

If liquid or moist solids enters the instrument, please immediately disconnect the power supply

and contact supportusa@hollandgreenscience.com

•

Surface stains on the instrument should be cleaned only by a clean, soft rag and detergent.

•

The power must be disconnected before any maintenance or cleaning.

•

Do not clean the instrument with any corrosive cleaning solutions.

•

If the instrument is left unused for a long period, switch ‘OFF’ the power and store within a

dry, clean, level, and stable surface at normal temperature.

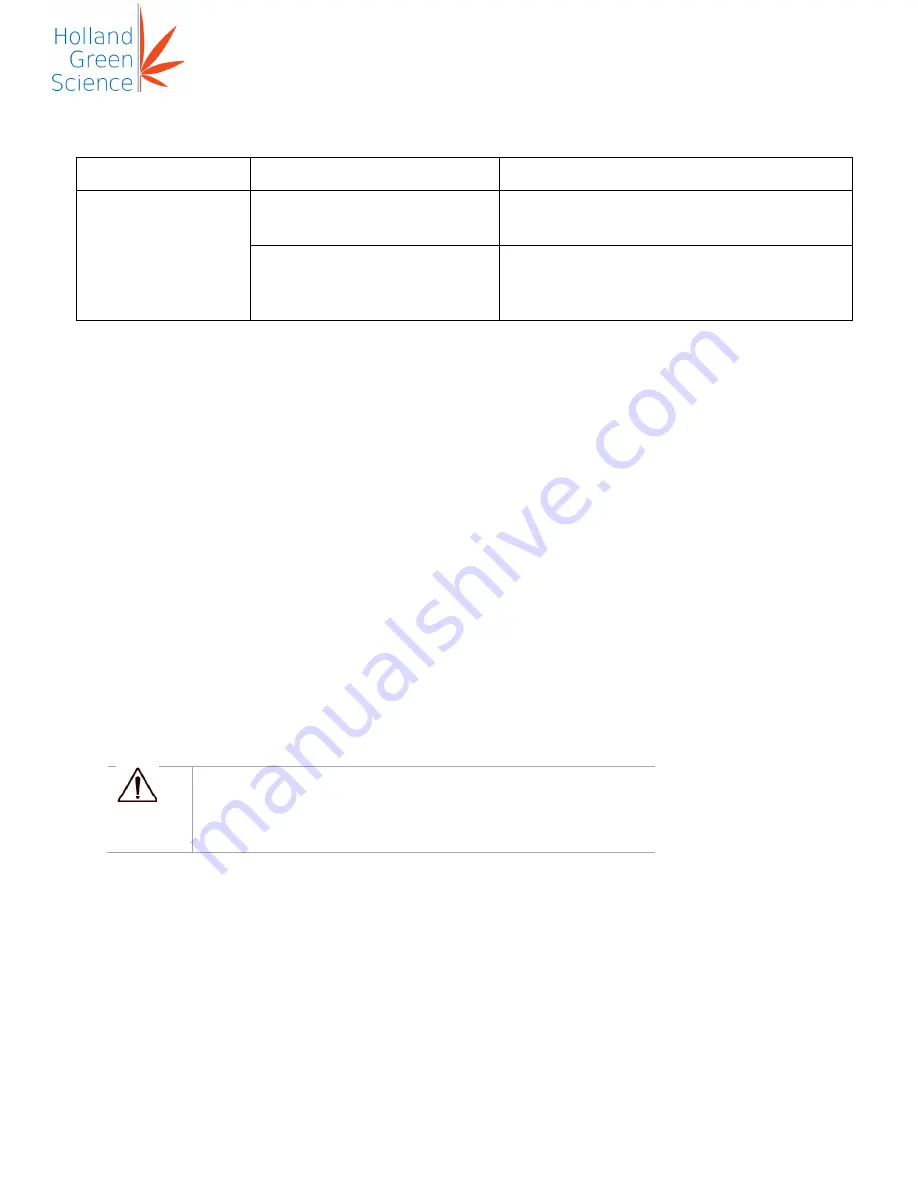

Problem

Causes

Solution

No power

The power cord is unplugged

or not plugged in correctly

Reinsert

Tripped Breaker

Reset once, if a further trip occurs,

contact

serviceusa@hollandgreenscience.com

Caution!

Before any Maintenance or Inspection, the Power Cable

MUST be removed from the power socket.