HL-190 D25 4WD/P/N / HL-220 D25 4WD/P/N

B-165DL25 4WD/P/N / B-195DL25 4WD/P/N

Rev. A

5/2/18

Page 38

8

Maintenance

8.1

Maintenance overview

Comment

The maintenance intervals given below are based on normal use of the scissor lift under normal

circumstances.

If the scissor lift is subjected to extreme conditions (such as dust, algae, bacteria or salt

deposits), then the frequency must be increased.

We count on your responsibility and expertise.

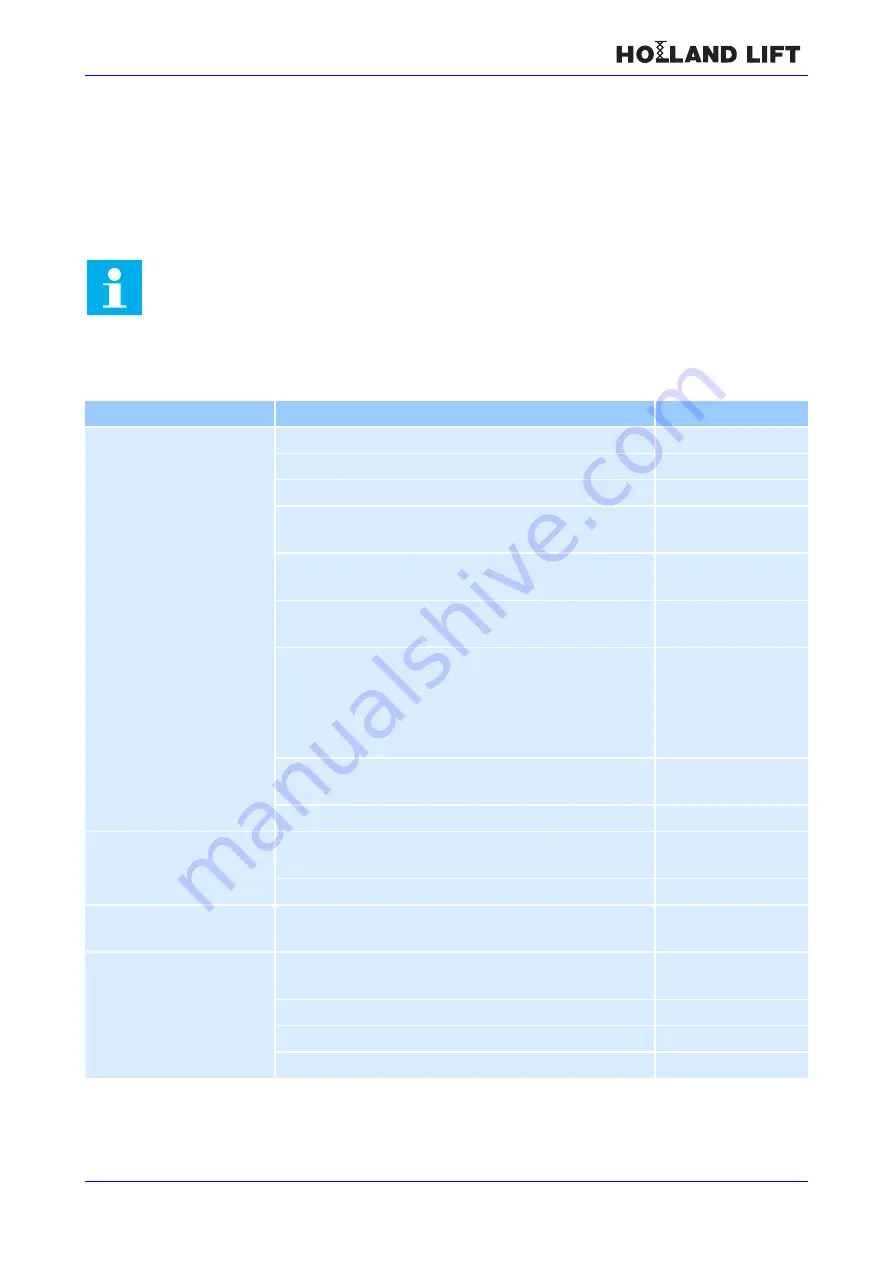

Component

Action

Frequency

Scissor lift

Check the entire scissor lift for damage.

Every day

Make sure the scissor lift works correctly.

Every day

Make sure the safety devices work correctly.

Every day

Make sure the stickers are legible. If necessary,

replace them.

Every day

Lubricate the scissor lift according to the overview of

the lubrication points.

Once a month

Check all the bolt connections. If necessary, tighten

them.

Once every

3 months

Check the maximum permitted lifting pressure at the

maximum working load and the maximum driving

pressure. Contact the manufacturer if the measured

maximum permitted lifting pressure is greater than the

stated maximum driving pressure.

Once every

3 months

Check all the sealed settings. Contact the

manufacturer if any seals are broken.

Once every

3 months

Have the scissor lift inspected by an expert.

Once a year

Scissor mechanism

Check the locks and the attachments.

Once every

3 months

Have the scissor mechanism inspected by an expert.

Every 5 years

Lifting cylinder

Check the locks and the attachments.

Once every

3 months

Hydraulic system

Check for damage and leaks. Repair any damage or

leaks.

Every day

Check the oil level. If necessary, top it up.

Every week

Replace the filter element.

Once a year

Change the oil.

Once a year