10

XL-LG20004UM-en-US Rev B · 2018-09-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Installation Procedures

6. Installation Instructions

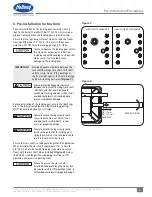

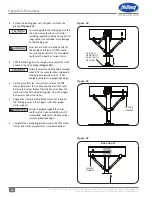

1. On a level surface, support the front of the trailer with

either a kingpin stand, or while coupled to a tractor

(Figure 13)

.

2. Set the parking brakes and chock the tires.

Failure to properly support the trailer and

chock the tires during installation of

landing gear could create a crush hazard

which, if not avoided, could result in

death or serious injury.

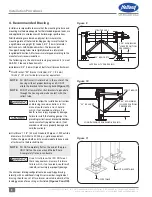

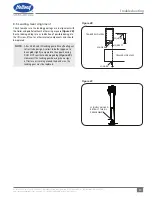

3. Using a square, check that the trailer landing gear

mounting surfaces are perpendicular to the ground and

parallel to each other.

4. Install the landing gear legs and cross-shaft to the

trailer frame. Torque mounting bolts to manufacturer’s

specifications. Ensure the cross shaft lock nuts are snug,

but cross-shaft is allowed side to side free-play.

5. Install the bracing. Refer to Section 4, (Recommended

Bracing), for the minimum bracing requirements. Torque

fasteners to manufacturer’s specifications.

IMPORTANT:

After installing the bracing, use a square

to ensure that the legs have remained

aligned with the trailer and each other

as illustrated

(Figure 14)

.

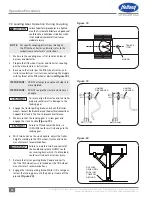

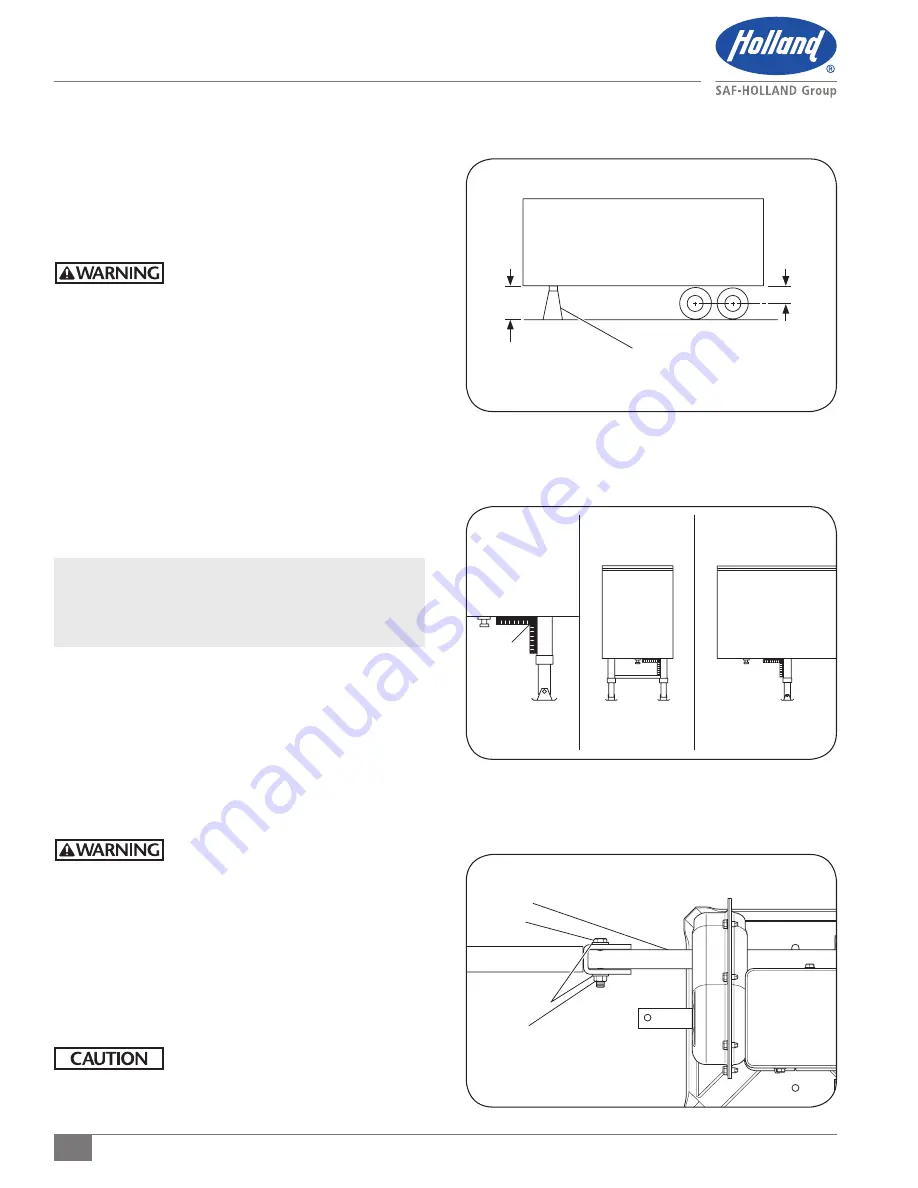

6. Install the crank handle onto the shift shaft. Position the

washers on the outside of the crank handle. Insert the bolt

through both the washers and the shaft, and secure with

nut

(Figure 15)

.

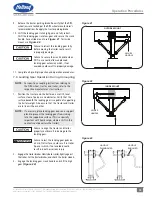

7. Ensure proper operation by extending and retracting

the landing gear. Verify the crank handle is allowed to

engage and disengage freely.

8. Extend the landing gear to ensure that both legs reach

the ground simultaneously.

Failure to maintain two hand control of

handle and release SLOWLY could cause

spring back which, if not avoided, could

result in death or serious injury.

9. Install the crank hanger, and ensure that the handle can

be adequately secured.

Locate Hanger on right-hand side of leg centerline for

outside mount.

Locate Hanger on left-hand side of leg centerline for

inside mount.

Failure to secure the crank handle when

NOT in use could, allow unplanned

landing gear extension which, if not

avoided, could result in property damage.

Figure 13

Figure 14

CORRECT

SQUARE

TRAILER

END VIEW

TRAILER

SIDE VIEW

SUPPORT AT KINGPIN

“A” RIDE

HEIGHT

FIFTH WHEEL

OPERATING HEIGHT

Figure 15

WASHERS

BOLT

SHAFT

NUT