13

XL-LG20004UM-en-US Rev B · 2018-09-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Operation Procedures

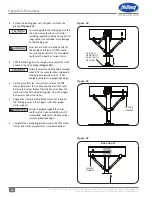

Figure 22

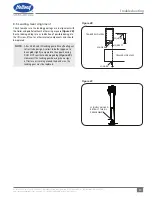

Figure 23

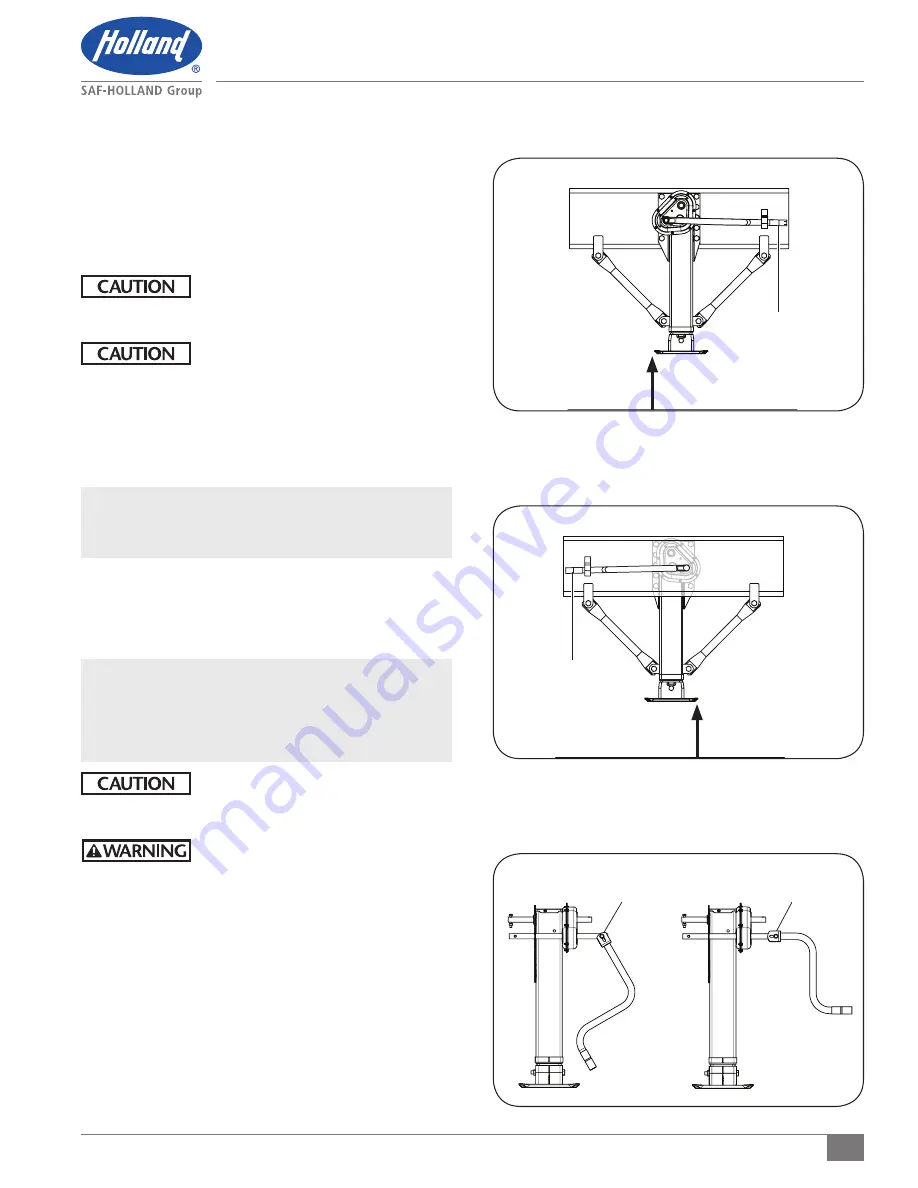

Figure 21

9. Release the tractor parking brake. Re-verify that the fifth

wheel jaws are locked per the fifth wheel manufacturer's

recommendations. Reapply the tractor parking brake.

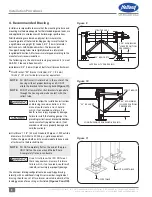

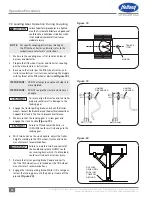

10. Shift the landing gear into high gear and fully retract.

Shift the landing gear into low gear and secure the crank

handle. For outside mount use

Figure 21

,for inside

mount use

Figure 22

.

Failure to retract the landing gear fully

before moving the trailer could result

in property damage.

Failure to secure the crank handle when

NOT in use could allow unplanned

landing gear extension which, if not

avoided, could result in property damage.

11. Complete all pre-trip inspection and operation procedures.

7.4 Landing Gear Operation During Uncoupling

NOTE:

For specific uncoupling instructions relating to

the fifth wheel, tractor, and trailer, refer to the

respective manufacturer's instructions.

1. Position the tractor and the trailer on a well lit, level

surface, clear of persons and obstacles. Verify that the

surface beneath the landing gear is capable of supporting

the trailer weight. Also ensure that the tractor and trailer

are in line with each other.

NOTE:

If necessary, place landing gear pads on a support

plank to prevent the landing gear from sinking

into the supportive surface. (This is especially

important with liquid cargo, where a shift in the

contents could overturn the trailer).

Failure to align the tractor and trailer

properly could result in damage to the

landing gear.

Failure to rest the landing gear pads on

a hard, flat surface, could result in trailer

tip-over which, if not avoided, could

result in death or serious injury.

2. Engage the trailer brakes. Slowly back tractor tightly against

the trailer. Set the tractor brakes, and chock the trailer wheels.

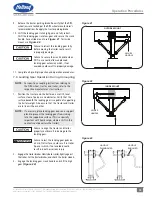

3. Engage the landing gear crank handle and shift to high

gear

(Figure 23)

.

SECURE

HANDLE

SECURE

HANDLE

OUTSIDE MOUNT

INSIDE MOUNT

HANDLE

ENGAGED

HANDLE

DISENGAGED