7

XL-LG20004UM-en-US Rev B · 2018-09-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Pre-Installation Procedures

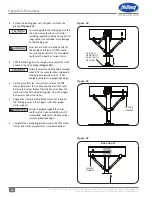

Figure 8

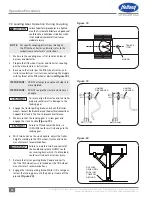

3. Pre-Installation Instructions

Prior to installation of the landing gear, correctly size the

legs to the trailer. There MUST be 12" (304.8 mm) minimum

ground clearance, when the landing gear is fully retracted.

Ensure that the legs have sufficient travel to raise the trailer

from the fifth wheel 1-3" (25.4 - 76.2 mm) without over-

extension. DO NOT force the landing gear past its stops.

Failure to operate the landing gear within

the maximum extension or retraction

including repeated winding to its physical

stops could, if not avoided, cause

damage to the landing gear.

IMPORTANT

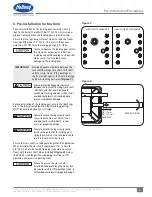

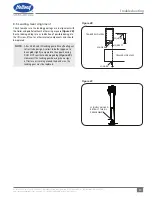

Provide adequate clearance between the

jack shaft bushings, jack shaft, shift shaft

and the trailer frame. If the bushings or

shafts are tight against the frame, damage

and hard cranking will result

(Figure 7)

.

Failure to provide adequate clearance

between the jack shaft bushings, jack shaft,

shift shaft, and the trailer frame could

cause hard cranking and wear which, if not

avoided, could result in minor/moderate

injury or component damage.

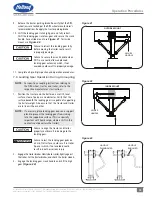

Before installation of the landing gear, ensure that both legs

are in the fully retracted position. Both landing gear legs

MUST be extended equally at all times.

Failure to extend the legs evenly could

cause trailer to tip over, which, if not

avoided, could result in death, serious

injury, or property damage.

Failure to extend the legs evenly could

increase the potential for landing gear

spring back, which, if not avoided, could

result in death or serious injury.

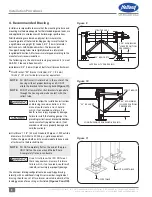

Ensure the cross-shaft is of adequate length for the application.

When installed, the cross-shaft should have 1/8" (3 mm) to

3/8" (9.5 mm) of side to side free play. It should also rotate

freely with the jack shaft when installed

(Figure 8)

. A cross

shaft which is too long will cause binding resulting in stiff

operation and excessive bushing wear.

Failure to ensure the cross-shaft is

installed at adequate length and has free

play could result in stiff operation which, if

not avoided, could result in property damage.

1/8

" (3 mm)

-

3/8

" (9.5 mm)

FREE PLAY

FREE ROTATION

Figure 7

SUFFICIENT CLEARANCE

INSUFFICIENT CLEARANCE