8

XL-LG20004UM-en-US Rev B · 2018-09-17 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Installation Procedures

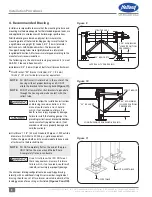

4. Recommended Bracing

Installers are responsible to ensure that the mounting structure and

mounting method are adequate for the intended imposed loads, use

and application in accordance with trailer design specifications.

Published ratings are based on physical tests wherein the

mounting plate of the tested landing gear legs was attached to

a rigid fixture using eight (8) Grade 8, 5/8" (16 mm) diameter

bolts and nuts with hardened washers. The lower end of

the upper housing tubes were rigidly braced in a lateral and

longitudinal direction. All fasteners were torqued according to the

manufacturer’s recommendations.

The following are the minimum bracing requirements to meet

AAR-931 Side Load Requirements:

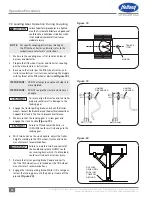

Hardware: 5/8" (16 mm) Grade 8 bolts for all brace attachment.

Strut Bracket: “W” Bracket (LG0266), 3/8" ( 9.5 mm)

thick x 2" (51 mm) wide (minimum) or equivalent.

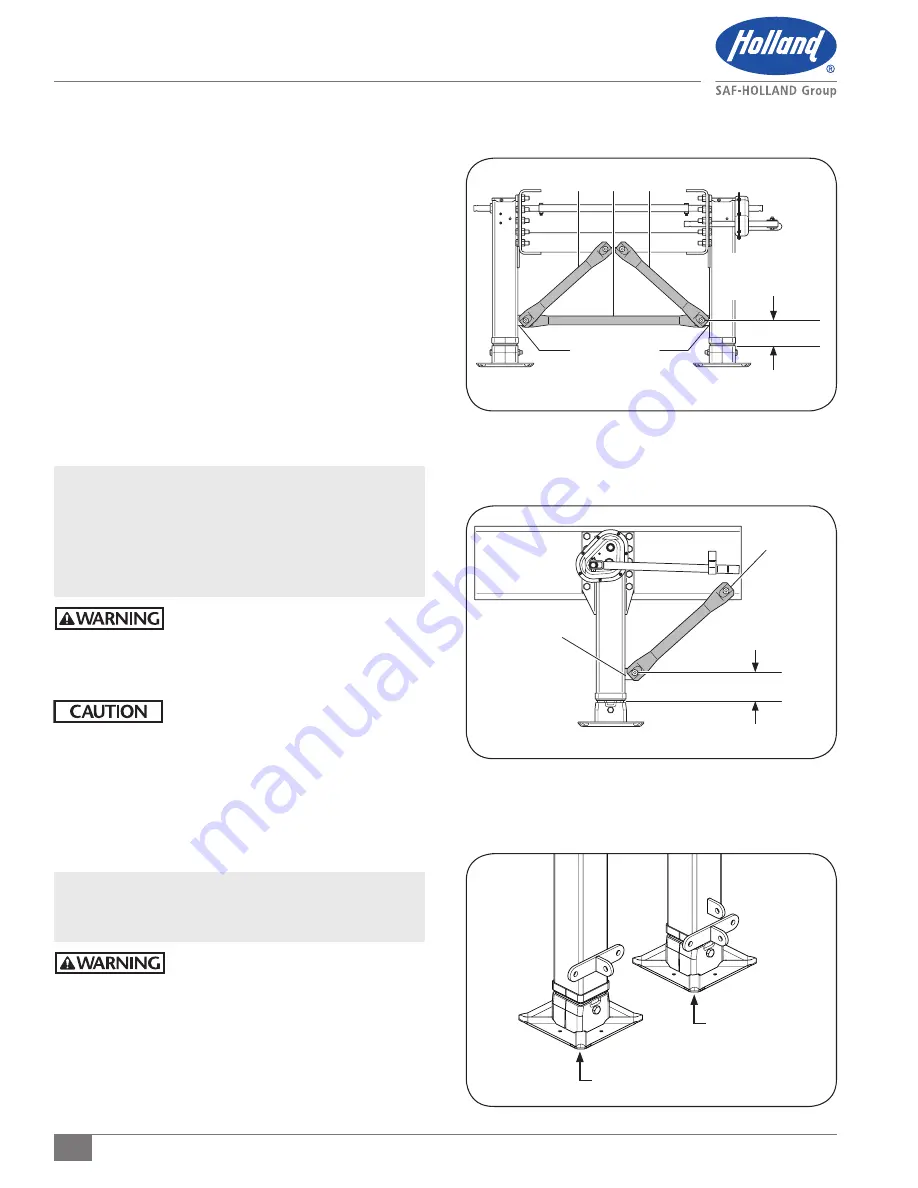

NOTE:

DO NOT install strut brackets in the center of the

housing without proper backing and DO NOT

attach the brackets to the housing band

(Figure 11).

NOTE:

DO NOT allow weld for strut brackets to penetrate

through the housing and make contact with the

retract tube.

Failure to follow the installation instructions

and bracing recommendations in this

manual could create a crush hazard

which, if not avoided, could result in

death, serious injury or property damage.

Failure to install, the landing gear per the

preceding instructions and recommendations

could cause faulty operation which, if not

avoided, could cause property damage and

void the warranty.

Strut Brace: 1-1/2" (38 mm) Schedule 80 pipe or 1.900 outside

diameter x 8 GA. Wall x 50,000 p.s.i. yield or equivalent.

Flatten the pipe on both ends to accommodate fasteners and

attachment to the brackets/trailer.

NOTE:

DO NOT completely flatten the end of the pipe.

ONLY flatten the area around the bolt hole.

A completely flat end can buckle.

Use of strut braces that DO NOT meet

these requirements may result in brace

failure which, if not avoided, could result

in death, serious injury or property damage.

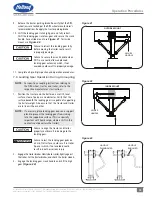

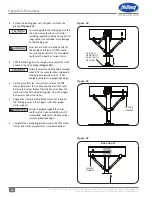

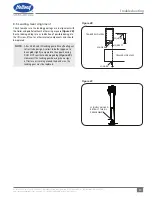

The minimum bracing configuration to be used: A-type bracing

laterally, with an additional straight cross member. Longitudinal

bracing should consist of two braces mounted rearward of the

landing gear, one for each leg as illustrated

(Figures 9 and 10).

Figure 10

Figure 11

LONGITUDINAL REARWARD BRACING

ACCEPTABLE

NOT ACCEPTABLE

F

igure

9

LATERAL A-TYPE BRACING

6.50" MAXIMUM

(LOWER POSITION

PREFERRED)

STRUT BRACES

STRUT BRACE

“

W

“

BRACKETS

6.50" MAXIMUM

(LOWER POSITION

PREFERRED)

“

W

“

BRACKET