3 MAINTENANCE PROCEDURES

3.1 As needed lubrication

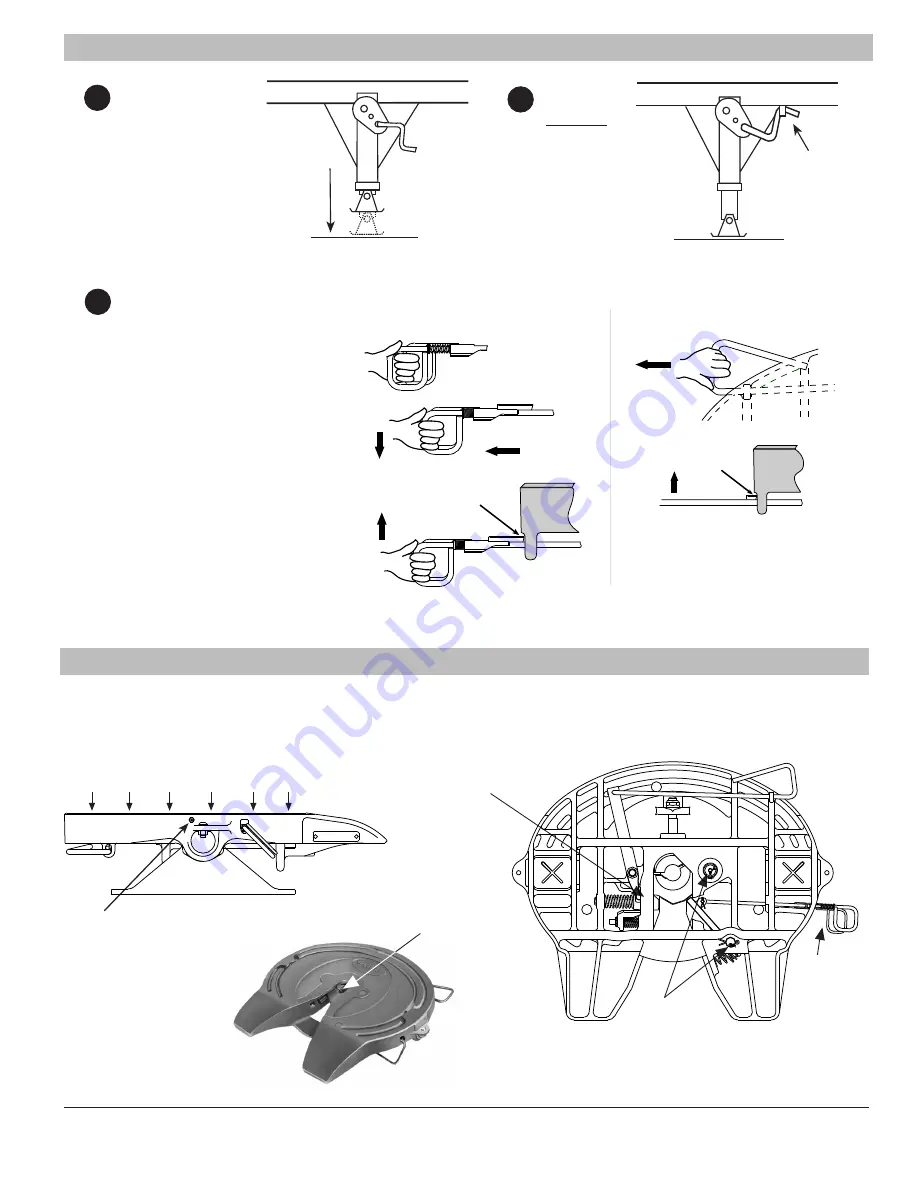

NOTE: Maintain adequate lubrication on the following surfaces by inspecting and

re-lubricating at regular intervals. Use a water-resistant, lithium grease.

LOCKING PLUNGER

SLIDING AND

ENGAGEMENT

AREAS

GREASE THE TRAILER

CONTACT SURFACE

GREASE

BRACKET

SUPPORTS

THROUGH

FITTINGS (x 2)

LOCK PIN

GREASE

FITTINGS

SLIDING

HANDLE

BAR

and

SPRING

LOCK JAWS

(kingpin

contact areas)

1

1

6

Extend landing

gear until pads

just touch

the ground

Switch to

low gear

and crank an

additional

4 - 8 turns

7

USE

LOW

GEAR!

Secure

handle

Unlock fifth wheel.

First open secondary lock:

8

2.3 Trailer uncoupling procedure (continued)

USE

HIGH

GEAR

1

grasp and pull inner

handle

2

move handle down

3

pull handle out

4

lift handle up and hook

handle "tab" on outer

edge of casting

1

1

2

))))))))))))))

2

3

))))))))))))))

HOOK HANDLE

"TAB" ON CASTING

))))))))))))))

HOOK "TAB"

ON CASTING

4

To Open

Secondary Lock

To Open

Primary Lock

Second, open primary lock:

1

pull handle straight out

2

lift handle up and hook

handle "tab" on outer

edge of casting

XD-71-D-E

XL-FW1083-01

6