WARNING

NOTE: Perform the following every three (3) months or 50,000 km, whichever comes

first. Thoroughly steam clean all components before inspecting or adjusting.

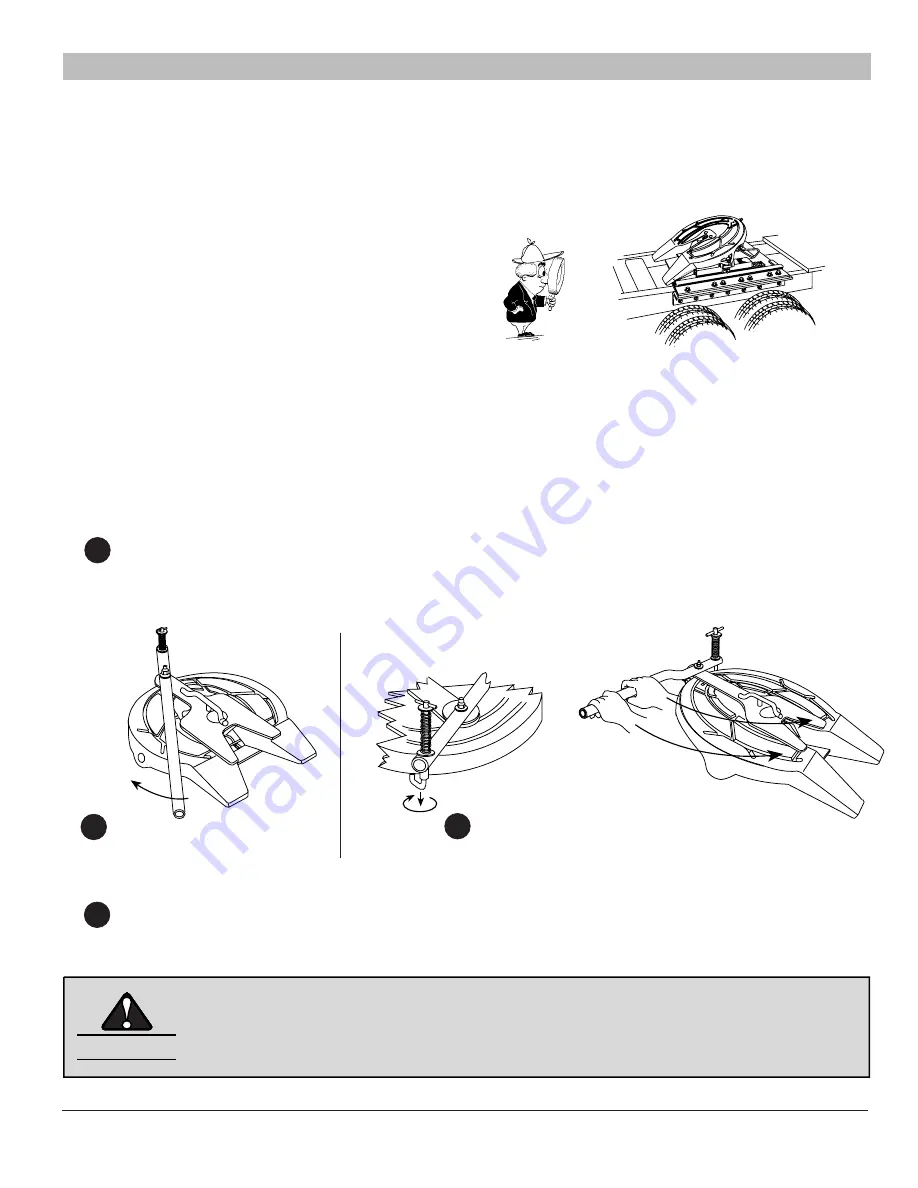

3.2.2 Inspection of Locking Mechanism

Verify the proper operation of the fifth wheel by locking and unlocking the

fifth wheel locks using Holland Kingpin Lock Tester TF-TLN-1000 or

TF-TLN-5001.

After each attempt, verify that the fifth wheel is properly

locked as shown below.

TO

LOCK

TO

UNLOCK

Set tool on fifth wheel

and rotate handle

Push down and rotate the

"J" hook under the fifth wheel,

then pull handle back

1

2

3

4

3.2 Required Inspections and Adjustments

NOTE: Perform the following every three (3) months or 50,000 km, whichever comes

first. Thoroughly steam clean all components before inspecting or adjusting.

3.2.1 General Fifth Wheel Inspection

Inspect the

fifth wheel

mounting

and

fifth wheel

assembly

Tighten loose bolts

and fasteners with

required torque

•

Replace missing

or damaged bolts

Replace bet, worn,

or broken parts

Use only genuine Holland parts kits

XL-FW1083 -01

7

If you do not obtain a proper couple, repeat the coupling sequence.

DO NOT USE ANY FIFTH WHEEL THAT FAILS TO OPERATE PROPERLY.

•

•