HOLMAN CONVEYOR TOASTERS

MODELS T710(H, TW, TX) T714(H, TW, TX) S710(H) S714(H) B710H

COOKING PROCEDURES CONT.

C.

MODEL

B710(H)

The model B710(H) has higher wattage tubes on the top than on the bottom,

therefore when placing the bun halves on the conveyor you should place

them cut side up.

D. DEEP TOASTING OR BAKING (Units with Variable Heat Controls).

Food products that require deep heating without exterior toasting may be

heated by reducing the oven temperature (lowering the top and/or bottom

heat controls) and cooking at slower speeds. Some foods may require more

top heat than bottom heat or vice versa. Every product will require some

experimentation to arrive at the correct balance of heat control and conveyor

speed settings. Each time a setting is changed allow about 5 minutes for the

unit to stabilize.

CLEANING PROCEDURES

1. Turn top and bottom heat controls to the OFF position.

2. For lightly soiled conveyor belts, turn conveyor speed control to fastest

setting (100) and wipe with a damp cloth.

3. For heavily soiled conveyors, turn conveyor speed control to fastest setting

(100) and wipe with a light abrasive pad.

4. Turn conveyor speed control off.

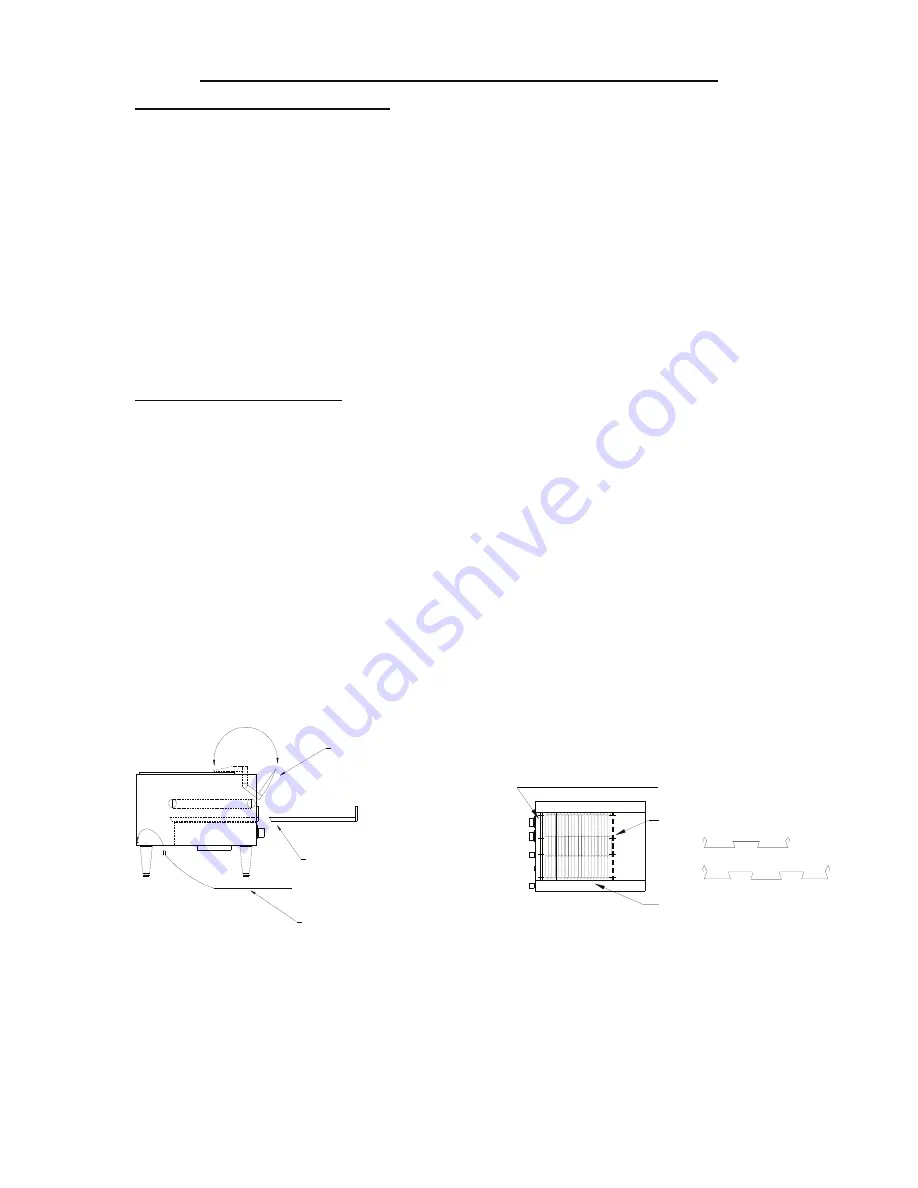

5. After the unit cools, remove interior crumb tray (as shown below) and clean.

Slide crumb tray back into position.

DO NOT OPERATE UNIT WITHOUT

CRUMB TRAY IN PLACE AS THIS CAUSES OVERHEATING IN THE

CONTROL BOX AND MAY ACTIVATE THE HEAT LIMIT SWITCH.

6. Wipe exterior surface of unit.

LUBRICATION OF DRIVE CHAIN WITH A GRAPHITE BASED LUBRICANT IS REQUIRED AS

PERIODIC MAINTENANCE. CALL HOLMAN FACTORY SERVICE DEPARTMENT FOR

DETAILS.

LOAD UP TRAY

HEAT REFLECTOR / CRUMB TRAY

TOAST CHUTE

CAUTION: DO NOT OPERATE UN

WITHOUT CRUMB TRAY AS

THIS CAUSES OVERHEATING IN

THE CONTROL BOX.

CONVEYOR BELT

IDLER SHAFT

DRIVE SHAFT

CONVEYOR LINK, MODEL T710

(TOP VIEW)

SHOWN WITHOUT TOP COVER

CONVEYOR LINK, MODEL T714

REVISED

9/10/2008

PAGE 5

OPERATOR'S MANUAL