12

13

CONTROLLER INSTALLATION

Mounting the Controller

Install the controller near a 240V AC outlet.

Preferably located in a house, garage, or exterior

electrical cubicle. For ease of operation, eye level

placement is recommended. Ideally, your controller

location should not be exposed to rain or areas

prone to flooding or heavy water.

Fasten the controller using the key hole slot

positioned externally on the top centre and

the additional holes positioned internally under

the terminal cover.

Electrical Hook-up

Warning

1. All electrical work must be carried out in

accordance with these instructions following

all applicable local, state and federal codes

pertaining to the country of installation. Failure

to do so will void the controller’s warranty.

2. Disconnect mains power supply before

any maintenance work to the controller

or valves is undertaken.

3. Do not attempt to wire any high voltage items

yourself (i.e. pumps and pump contactors

or hard wiring the controller power supply

to the mains). This is the field of a licensed

electrician. Serious injury or death could result

from improper hook up. If in doubt consult your

regulatory body as to what is required.

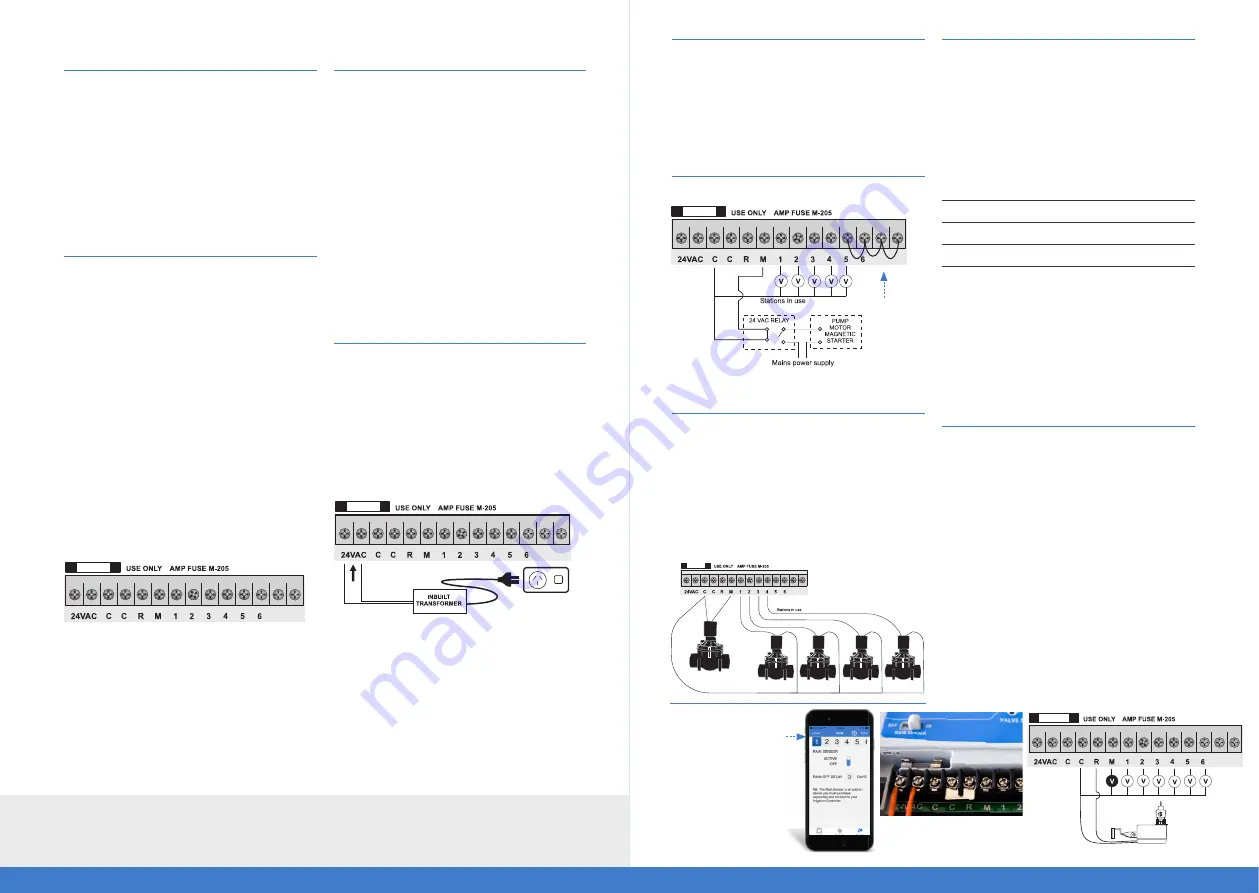

Terminal Block Layout (8 zone example)

Field Wiring Connections

Preparation

1. Prepare wire for hook-up by cutting the wires to

the correct length and stripping approximately

0.25 inches (6mm) of insulation from the end to

be connected to the controller.

2. Ensure terminal block screws are loosened

sufficiently to permit easy access for wire ends.

Insert stripped wire ends into the clamp aperture

and tighten screws. Do not over tighten as this

may damage the terminal block.

3. A maximum of 0.75 A may be supplied

by any output. Check the inrush current

of your solenoid coils before connecting

more than two valves to any one zone.

This can be done by using the Pump Protection

(System Test) feature on page 14.

Power Supply Connections

Inbuilt transformer

It is recommended that the transformer is

not connected to a 240V AC supply which

is also servicing or supplying motors

(i.e. air conditioners, pool pumps, refrigerators).

Lighting circuits are suitable as power sources.

The inbuilt transformer must be installed in an area

which is not exposed directly to the weather.

GLOSSARY

24 VAC:

24V AC power supply connection.

C:

Common wire connection to field wiring.

R:

Input for rain switch.

M:

Master valve or pump start output.

Z1–Z8:

Zone (valves) field connections.

Pump Start Relay Connection

(Water supply by pump system)

This controller does not provide mains power

to drive a pump. A pump must be driven via an

external relay and contactor setup as detailed

below. The controller provides a low voltage signal

that actuates the relay which in turn enables the

contactor and finally the pump.

Single Phase Pump Installation

Note: It is recommended to always use a relay

between the controller and the pump starter.

Master Valve Installation

(Water supply off mains water)

The purpose of the master valve is to shut

off the water supply to the irrigation system

when there is a faulty valve or none of the zones are

operating correctly. It’s used like a back-up valve

or fail safe device and is installed at the start of the

irrigation system where it is connected to the water

supply line.

Zone Valve Installation

Up to two 24V AC solenoid valves can be

connected to each zone output and wired back to

the Common (COM) connector. When using long

runs of cables, be aware that voltage drop can play

a significant role, especially when more than one coil

is wired to a single zone.

As a good rule of thumb select your cable as

follows:

0–50m

cable dia 0.5mm

50–100m

cable dia 1.0mm

100–200m

cable dia 1.5mm

200–400m

cable dia 2.0mm

When you are using multiple valves per zone the

common wire needs to be much larger as it needs

to carry more current. In these circumstances

choose a common cable one or two sizes larger

than required. When making connections in the

field, only ever use gel filled or greased filled

connectors. Most field failures occur due to poor

connections. The better the connection here, and

the better the waterproof seal, the longer the system

will perform without trouble.

Rain Sensor Installation

You can connect a rain sensor to the controller

which will delay scheduled watering when it detects

rainfall. You can enable the rain sensor and set how

many days of watering will be delayed on the app.*

The sensor switch, accessed on the fascia, must be

up in the ON position. To over-ride the sensor when

it is wet, simply move the sensor switch down to the

OFF position. This will allow automatic and manual

watering cycles to operate.

Connecting the rain sensor wires:

a) Remove the link connector by loosening both

screws and slide out. (Link located under the

terminal cover).

b) Connect the two sensor wires into the

terminal block and replace where the link was.

Fasten one wire into C and the second to R.

1

7

8

1

7

8

1

7

8

Link any unused

zones to the last

active valve.

Valve Common Wire

Master Valve

Valve 1

Valve 2

Valve 3

Valve 4

1

7 8

2

1

7

8

* The rain delay commences when the rain sensor dries out.

Rain Sensor Installation

On the app, select the zone

you wish to enable the rain

sensor for. Switch toggle

to ‘Active’. Scroll to the

number of days required to

delay. Select ‘Done’. Select

‘Update’ on the Manage My

Devices screen. Repeat for

other zones if necessary.