MAINTENANCE PROCEDURES

A. REPLACING HEATER TUBES

1)

DISCONNECT UNIT FROM POWER SOURCE.

2) Remove the enclosure, by removing screws. Lift back end of enclosure up then back.

3) Remove heater tube wires from terminal block connection, keeping top and

bottom wires separate.

4) Lift heater tube retainers by loosening retaining screws and sliding the retainer plate up.

Hand tighten the plate to hold it up so the heater tubes will slide out freely.

5) Gently, pull defective heater tube out of unit.

6) Gently, put new heater tube into unit.

7) Loosen retainer screws and slide the retainer back into place. Tighten the screw to

secure the retainer in place over the ends of the heater tubes.

8) Reinstall the wires being sure use the same location as was in the original heater tube.

Tighten the screws securely.

B. REPLACING FAN MOTOR

1)

DISCONNECT UNIT FROM POWER SOURCE

.

2) Remove the enclosure, by removing screws. Lift back end of enclosure up then back.

3) Unplug power supply cord from fan motor.

4) Remove (4) screws, which hold fan motor and grill to bottom of unit and remove fan.

5) Put replacement motor and grill in place and secure to the bottom of unit with screws.

6) Reconnect power supply cord to fan motor.

7) Replace back panel and enclosure. Fasten with screws removed in step 2.

C. REPLACING CONVEYOR DRIVE MOTOR

1)

DISCONNECT UNIT FROM POWER SOURCE.

2) Remove enclosure and back panel.

3) Remove sprocket from motor shaft, using an Allen wrench and loosening the set-screw.

4) Remove the wire from terminal block connecting the drive motor to internal wiring.

On units rated 208 or 240 volts, note which color leads are being used for these connections

and which lead is capped with white tape. The new motor should use the same arrangement.

5) Remove screws holding motor in place and remove motor from unit.

6) Put new motor in place and attach loosely with mounting screws.

7) Replace sprocket on motor shaft.

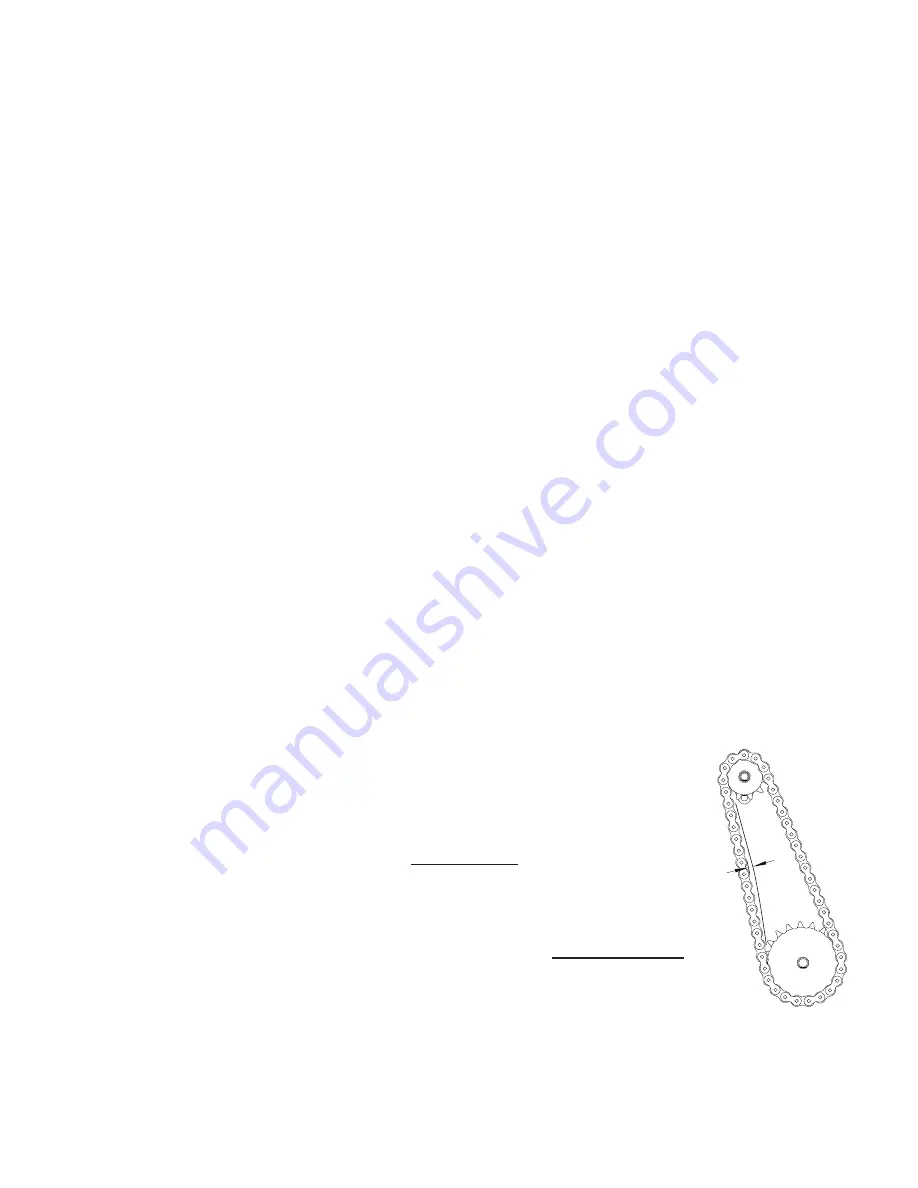

NOTE: The two sprockets must line up parallel with each other, so the chain does not twist any

during operation. Also the hub gets installed closets to the motor.

8) Slide motor until the drive chain has about 1/4” slack when

lightly pushed at the center of its top open run.

See chain tensioning illustration

.

9) Tighten screws to secure motor.

10) Rewire leads same as removed in step 4.

11) Replace side panel and control box cover.

D. CLEANING AIR INTAKE

ONCE A WEEK

1)

DISCONNECT UNIT FROM POWER SOURCE.

2) Place unit on its backside.

3) Use a vacuum cleaner and or a damp cloth to clean

the air intake. This procedure should be done at least

E. LUBRICATE THE CHAIN & SPROCKETS

EVERY 6 MONTHS

1)

DISCONNECT UNIT FROM POWER SOURCE.

2) Remove enclosure exposing chain drive.

3) Using an extreme pressure, synthetic chain lubricant with a

temperature range up to 400°F. Apply liberally onto chain

and sprockets. This grease is available as part no. 1P-Z8914.

4) Replace enclosure, Reconnect power source and test unit.

1/4”

QCS/RCS Chain Tension