TROUBLESHOOTING GUIDE

A. UNIT WILL NOT HEAT, CONVEYOR BELT WILL NOT MOVE.

1) Be sure the main circuit breaker is switched to the ON position and there is power to the outlet.

2) Check to see if the toaster is plugged in and all controls are turned to the ON position.

3) Be sure the Hi-Limit Reset Button is pushed in.

4) Call the Star Service Help Desk at 1-800-807-9054.

B. UNIT WILL NOT HEAT, CONVEYOR TURNS PROPERLY.

1) Check to see if the heat controls have been turned to the maximum setting.

2) Press the Hi-Limit Reset Button located on the end under the conveyor belt.

If this reactivates the heater tubes, see Hi-Limit Reset Section below.

3) Call the Star Service Help Desk at 1-800-807-9054.

C. HI-LIMIT (HEAT) RESET.

Your Holman conveyor toaster is equipped with an automatic activated temperature limit switch which interrupts

the heater tube connections if the air temperature in the control box exceeds 190°F (88°C) This limit switch can

be reset manually by pushing the button in the center of the switch which is located on the right side under the

conveyor belt. See Oven Components on Page 7 for location. Unit will not reset until internal temperature has

fallen below 190°F (88°C).

NOTE: THE HI-LIMIT SWITCH CAN BE ACTIVATED IF THERE IS NOT A PROPER AMOUNT OF

AIR FLOW BEING GENERATED BY THE COOLING FAN. IF THIS OCCURS:

1)

DISCONNECT UNIT FROM POWER SOURCE.

2) Check to see if the air intake area is free of dust, grease or other obstructions.

3) Check to see if crumb trays (heat reflectors) are in place.

If the Hi-Limit Switch can not be reset, call the Star Service Help Desk at 1-800-807-9054.

NEVER OPERATE UNIT WITHOUT CRUMB TRAYS IN POSITION AS THIS CAUSES

OVERHEATING IN THE CONTROL BOX.

D. CONVEYOR WILL NOT TURN, UNIT HEATS PROPERLY.

To check for mechanical binding:

1)

DISCONNECT UNIT FROM POWER SOURCE.

2) Check to see if there are obstructions in the conveyor

system that may cause a jam. If so, remove

obstruction.

3) Check power supply & terminal blocks for loose or

disconnected wires.

4) Check to see if the two sprockets are properly

aligned. Refer to

SPROCKET ALIGNMENT

previous

section.

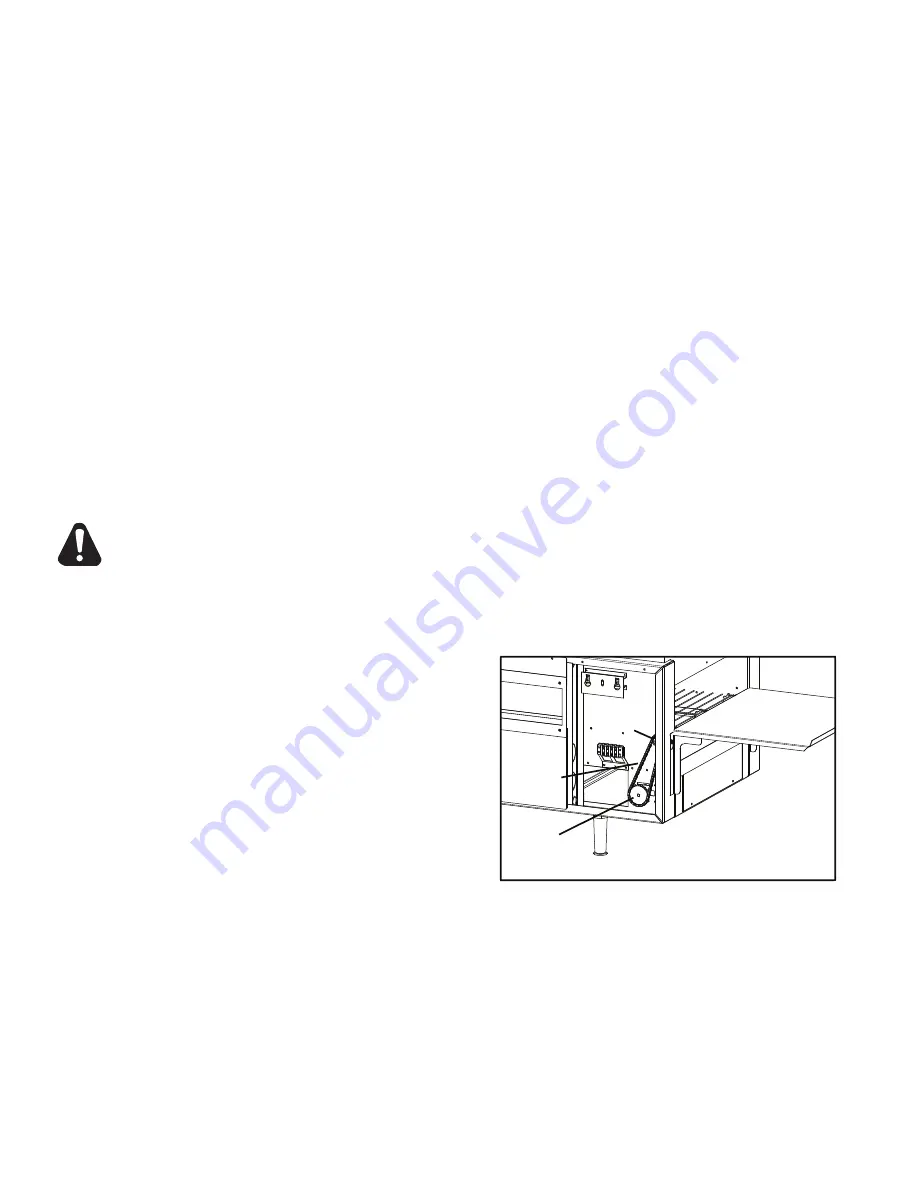

5) Remove side panel exposing the drive motor

sprockets, see illustration. Manually move conveyor

belt to check for mechanical binding. If conveyor belt

moves freely, call the Star Service Help Desk

at 1-800-807-9054. The drive motor or speed control

may have to be replaced.

E. COOLING FAN DOES NOT START

1) Check fan blade for obstruction, or broken blades.

2) Check electrical connections are secure and complete & the Hi-Limit Switch is working properly.

3) If only one of the two fans are working, and all connections are good, replace the fan.

Refer to

REPLACING FAN MOTOR

in the previous section.

4) If both fans are not working, chances are the fan switch needs replacing.

3) Call the Star Service Help Desk at 1-800-807-9054, as the fan switch and or fan motor

MAY

need

replacing.

IL1161

Drive

Sprocket

Chain

Driven

Sprocket

CAUTION