Avoid running square corners in unfinished areas, go straight across. Most traps are

created by using many elbows and right angle turns. Soft copper may be used in

situations requiring many turns. Be careful that soft copper doesn't sag and cause

traps.

When all the collector piping is finished, cap off the lines and leak test the collector array

before final connection to the tank. Flush the lines with water, then connect to the tank.

A removable union may be placed in the return line at the tank to add water and water

treatment. The boiler drain at the bottom of the tank can also be used. Do not fill the

tank until the startup procedure.

3.3

Pipe Insulation

The recommended insulation for outside piping is 1 inch wall isocyanurate foam

covered with an aluminum jacket. Elastic foam products are not recommended

because they deteriorate badly in sunlight and at high collector temperatures.

Fiberglass pipe insulation can be used as a second choice, but it has a lower R value

than the rigid foam products. Use the next thickness up.

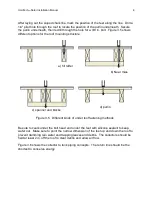

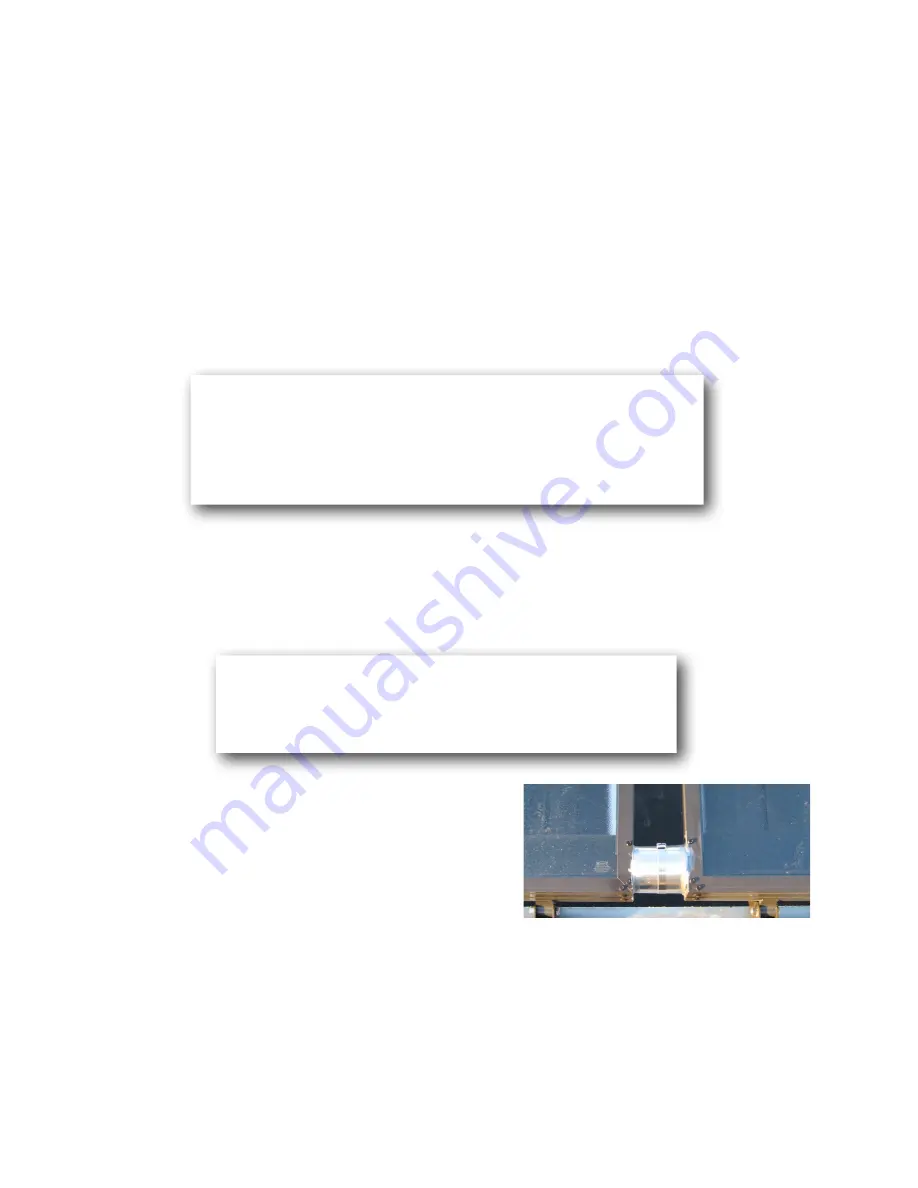

Insulate all piping between the collectors. Apply

silicone sealant between the pipe jacket and the

collector box to keep water from getting in and

wetting the insulation. All jacket connections and

joints should be water tight and lapped like

shingles to shed water.

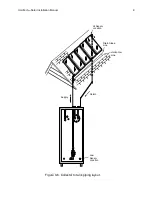

Leave the insulation off the return line from the last

collector for installation of the collector temperature

sensor. The insulation is installed over the sensor. It

is recommended that the collector sensor wiring be run under the aluminum jacket to

eliminate conduits and protect the collector sensor and wiring from lightening strikes.

Inside the building isocyanurate foam or fiberglass insulation with either an aluminum or

white craft paper covering (called All Service Jacket, ASJ) can be used.

HoloTech

tm

Solar Installation Manual

14

Note

Proper Insulation of the lines is one of the most important

steps to good performance and long life. A poorly insulated

system can waste half the energy collected and create severe

control problems

.

Note

Water that gets under the pipe insulation can enter the

building through the roof boot.

Figure 3.10. Insulation between

collectors.