OPERATION

HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

57

ED400FD | ED400FDDIG

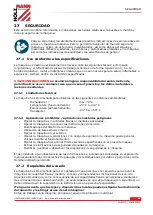

19.5.2

Longitudinal Turning

During facing, the planer tool is moved parallel to the axis

of rotation. The feed is carried out either manually by

turning the handwheel on the lathe slide or on the upper

slide or by switching on the automatic feed. The infeed for

the cutting depth is effected via the cross slide.

19.5.3

Plain Turning and Recessing

When facing, the turning tool is moved at right angles to

the axis of rotation. The feed is done manually with the

handwheel of the facing slide. The feed of the cutting depth

is effected by the top slide or the bed slide.

19.5.4

Fixing the Lathe Slide

The cutting force occurring during facing, grooving or

cutting-off operations can cause the lathe slide to move.

Therefore fasten lathe slide with the fixing screw.

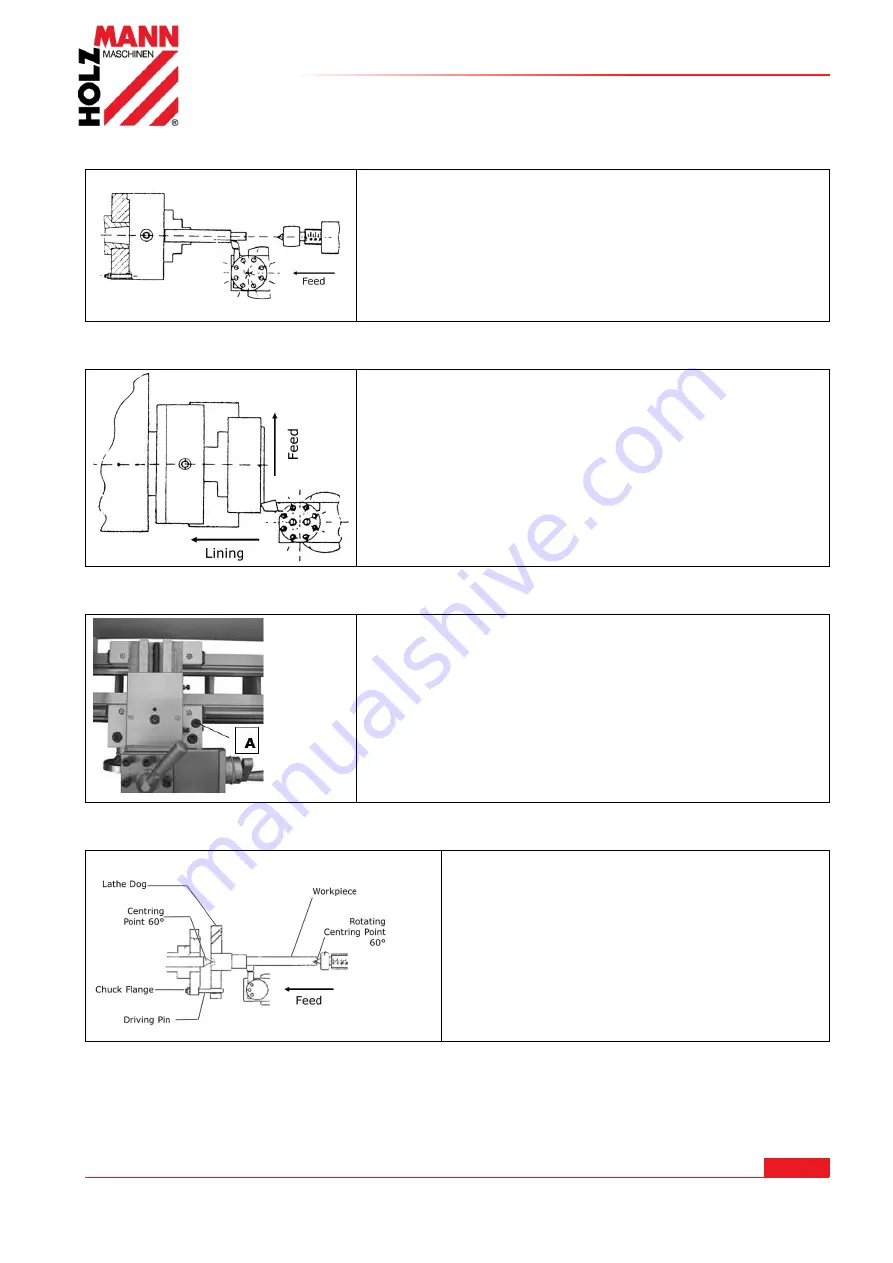

19.5.5

Turning between Tips

Workpieces that require a high concentricity are

machined between the tips. A centre hole is

drilled in both face turned faces of the

workpiece. The turning heart is clamped onto

the workpiece. The driving pin, which is screwed

into the chuck flange, transmits the torque to

the rotary heart. The fixed centering point is

located in the centre hole of the workpiece on

the spindle head side. The rotating center point

is located in the centering hole of the workpiece

on the tailstock side.