MAINTENANCE

HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

73

ED1080ADIG

20.1.1

Adjusting the taper gibs

Too much play in the guideways can be reduced by adjusting the taper gibs. To adjust, turn the

adjustment screw clockwise. This pushes the taper gibs backwards and reduces the clearance of

the respective guideway.

20.1.2

Visual inspection of oil levels

Check oil levels of headstock (1), feed gear (2) and apron (3) before starting work or after every

maintenance and repair. Oil level must reach at least to the middle or top mark.

20.1.3

Oil change headstock, feed gear and apron

N O T I C E

Lubricants are toxic and must not be released into the environment. When

changing, use suitable collecting containers with sufficient volume! Follow

the manufacturer's instructions and, if necessary, contact your local

authority for further information on proper disposal.

Supply gear oil (recommended for ISO 12925-1 CKD, DIN51517 Part 3 CLP, US Steel 224, AGMA

9005-E02) with a viscosity of 220.

Summary of Contents for ED1080ADIG

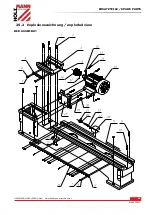

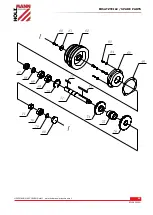

Page 84: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 84 ED1080ADIG 2...

Page 85: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 85 ED1080ADIG...

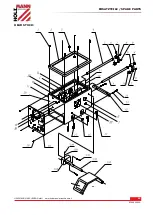

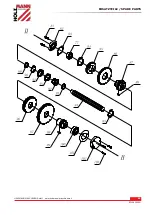

Page 86: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 86 ED1080ADIG...

Page 87: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 87 ED1080ADIG...

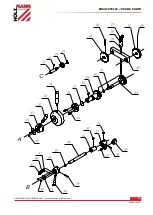

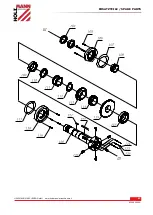

Page 88: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 88 ED1080ADIG 6...

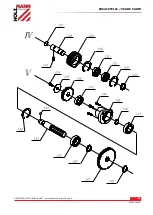

Page 93: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 93 ED1080ADIG 2...

Page 94: ...ERSATZTEILE SPARE PARTS HOLZMANN MASCHINEN GmbH www holzmann maschinen at 94 ED1080ADIG 3...