ASSEMBLY

HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

42

HOB 260ABS

To ensure proper transport, also observe the instructions and information on the transport

packaging regarding centre of gravity, attachment points, weight, means of transport to be used

and the prescribed transport position, etc.!

The machine is transported with the integrated castors, which can be folded up for the purpose of

changing location.

ASSEMBLY

15.1

Preparatory Activities

15.1.1

Checking the delivery content

Check the machine immediately after delivery for transport damage, missing parts and loose

screw connections. Report any damage or missing parts immediately to your dealer or freight

forwarder. Visible transport damage must be noted immediately on the delivery note in

accordance with the warranty provisions, otherwise the goods are deemed to have been properly

taken over.

15.1.2

Selecting a suitable installation location

Choose a suitable place for the machine.

Pay attention to the safety requirements and the dimensions of the machine.

The selected location must ensure a suitable connection to the electrical supply as well as

the possibility of connection to an extraction system.

Make sure that the floor can support the load of the machine.

The machine must be levelled simultaneously at all support points.

It is also necessary to guarantee a distance of at least 0.8 m around the machine.

In front of and behind the machine, the necessary distance must be provided for the

feeding of long workpieces.

15.2

Assembly of the Parts Dismantled for Transport

The machine is pre-assembled. The parts that have been disassembled for transport must be

assembled before use. Follow the instructions below:

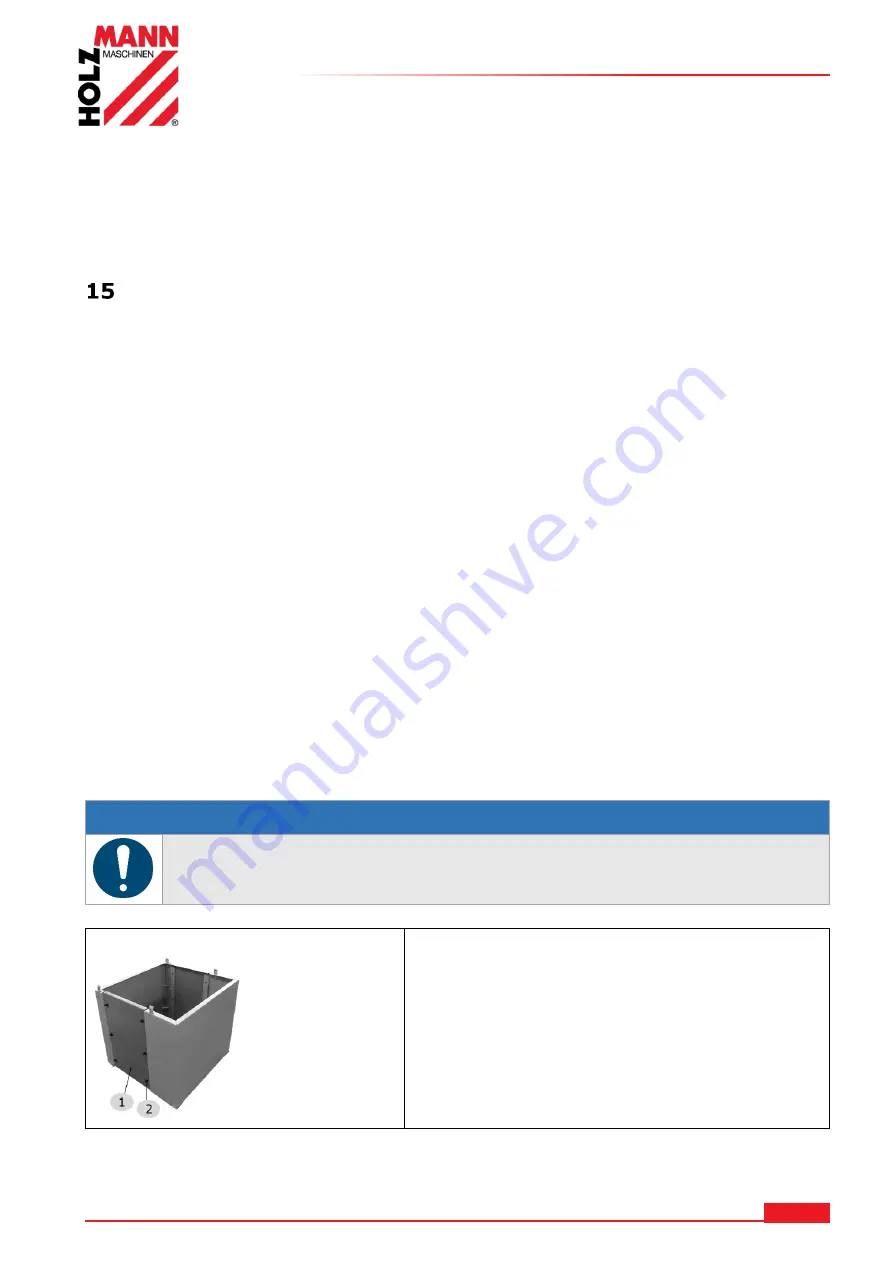

NOTE

After assembly, fasten the planer thicknessing machine to the floor with screws.

1.

Assembly socket

Mount the red socket elements (1) between the

grey elements.

You need six screws and washers (2) for each

element.