HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

Strana 20

mobilní olepovačka hran / mobile edge banding machine KAM 55V

Set the feed plate (4) on the corresponding plate thickness and edge width and secure it with

the locking lever (2).

Place the edge banding with the laying (4) on the workpiece to be machined plate and turn the

feed using the button (1) on the handle (22).

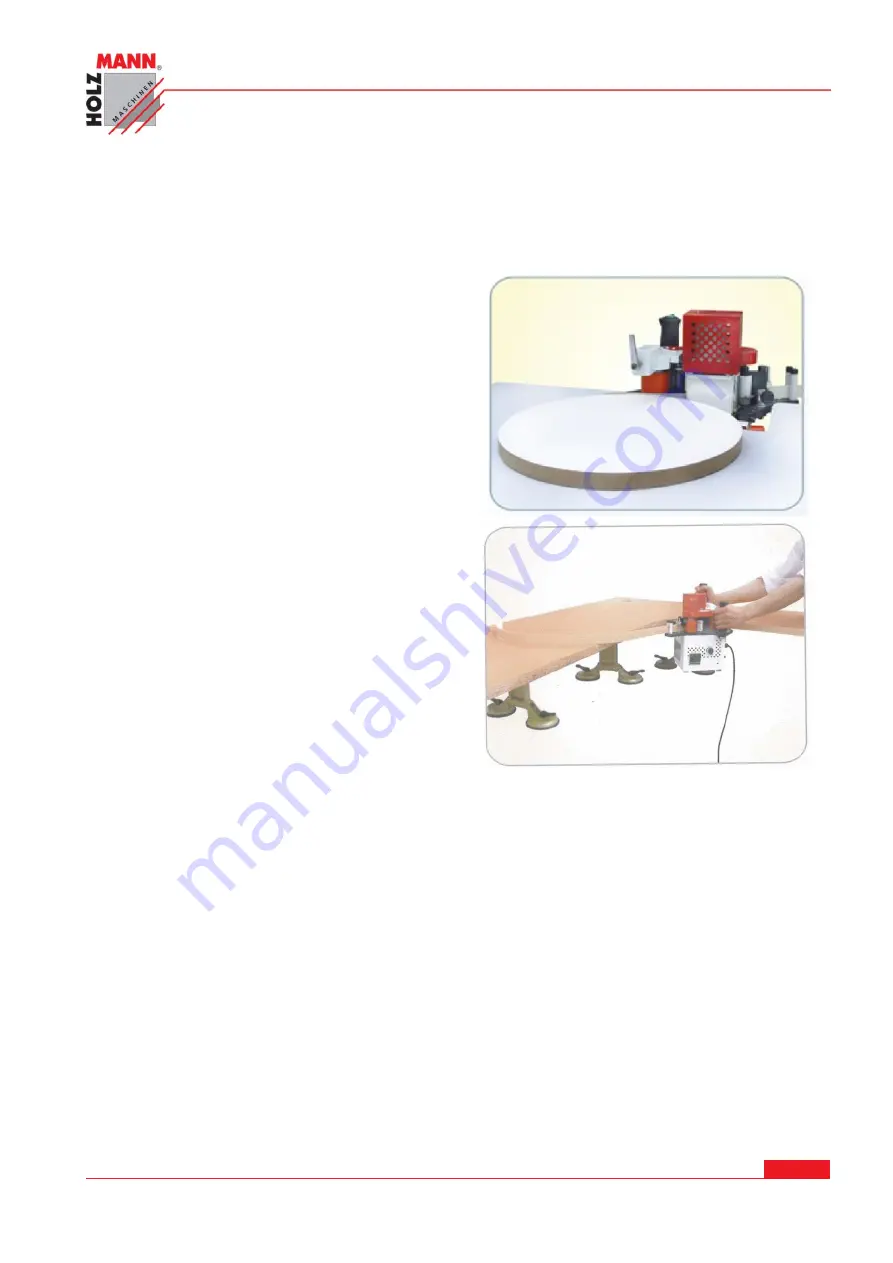

For large workpieces, straight and bent:

If necessary, fix the workpiece with the 2

uprights Vaccum suction.

Remove the base plate (4) from the device.

Run the KAM 55V as shown in the image along

the workpiece edge.

Protruding edges of material can be removed

with the Endtrimmer.

Lateral projections with the 2-pages trimmer.

WARNING: end and side trimmers are only for

material thickness up to max. 0.8 mm provided!

Please note the minimum bend radius of 25mm

ABS and PVC edges.

3mm edges are difficult to glue on curved

workpieces. Only with special glue, cleaner

workpiece edge, edge material and workpiece

11.2.4

Stationary Application:

For small, managable pieces

Remove from the support plate (4) from the edge banding.

Install the 4 leveling feet to the countertop. -

see exploded view page 27-

Attach the construction on the lower surface (this hole on each leveling foot)

Mount the KAM 55V to the countertop.

The speed (feed rate) of the adhesive roll is variable from 0.3 to 3 m / min, adjustable.

The workpiece you have to do it manually.

That is, for ideal results is manually the work as evenly as possible to supply with light pressure

on the roller.

Protruding edge material can be removed with the Endtrimmer.

Summary of Contents for KAM 55V

Page 32: ......