HOLZMANN MASCHINEN GmbH www.holzmann-maschinen.at

Strana 38

DLABAČKA–MORTISING MACHINE-TALADRO HORIZONTAL-PERCEUSE HORIZONTALE- WIERTARKO - FREZARKA LBM 250C

14.2

Operation

14.2.1

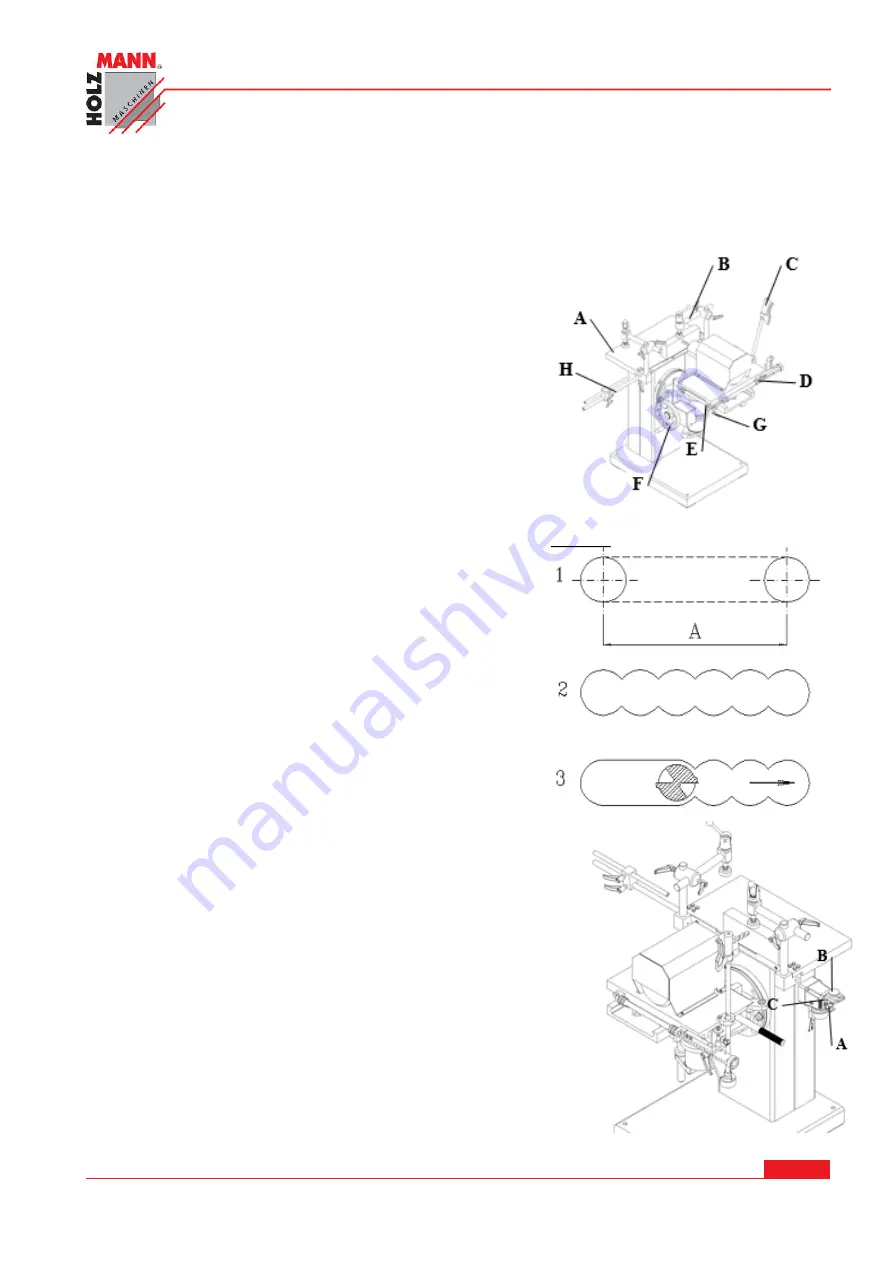

Drilling the holes

Drills with diameter of the shank up to Ø20 mm may be

placed in the clutch. The instrument should be bolted by

means of the wrench added to the clutch.

The detail is fixed to the working board

A

fig. 8 by

means of the binding clips

B

.

The horizontal motion of the table is effected through

the lever

C

. The horizontal motion of the table may be

limited by the nuts

D

and

E

.

The requested height of the machine is adjusted by

means of the hand wheel

F

, once the handle

G

is

unscrewed and is fixed by the same handle at the

requested height.

The running is measured by the scale.

The function of the catch H is to adjust the machine to

serial operation.

14.2.2

Working the grooves

During working out of grooves the sequence as per fig. 9

should be followed, i.e.:

1.

Drilling of two holes at the beginning and the end of

the groove.

2.

The holes are drilled along the whole length of the

groove, as shown on the diagram, position2

3.

The specific holes are jointed by transversal running of

the drill – position 3.

ATTENTION!

Don’t working with removed guard

cover by chuck.

14.3

Control panel operation functions

A

- Knob - green. Starts the machine. Operated by push.

B

- Emergency button cap – for emergency stopping of machine.

Actuated by pressing. It is released by opening the cap. When

the button is not released the machine cannot be started.

C

- Knob - red. Stops the machine. Operated by push.

Starting:

Before starting the machine check always the safety

facilities. Observe the recommendations for safety of

work according the manual.

The machine is starting by pressing the green button A.

Stopping:

Normal shut-down:The machine is stopped by pressing the red

button C, which stops the motor.

Emergency shut-down:The emergency shutdown is effected by

pressing the emergency button B, which stops the motor.