20

ADH-Series | Version 1.02

Operation

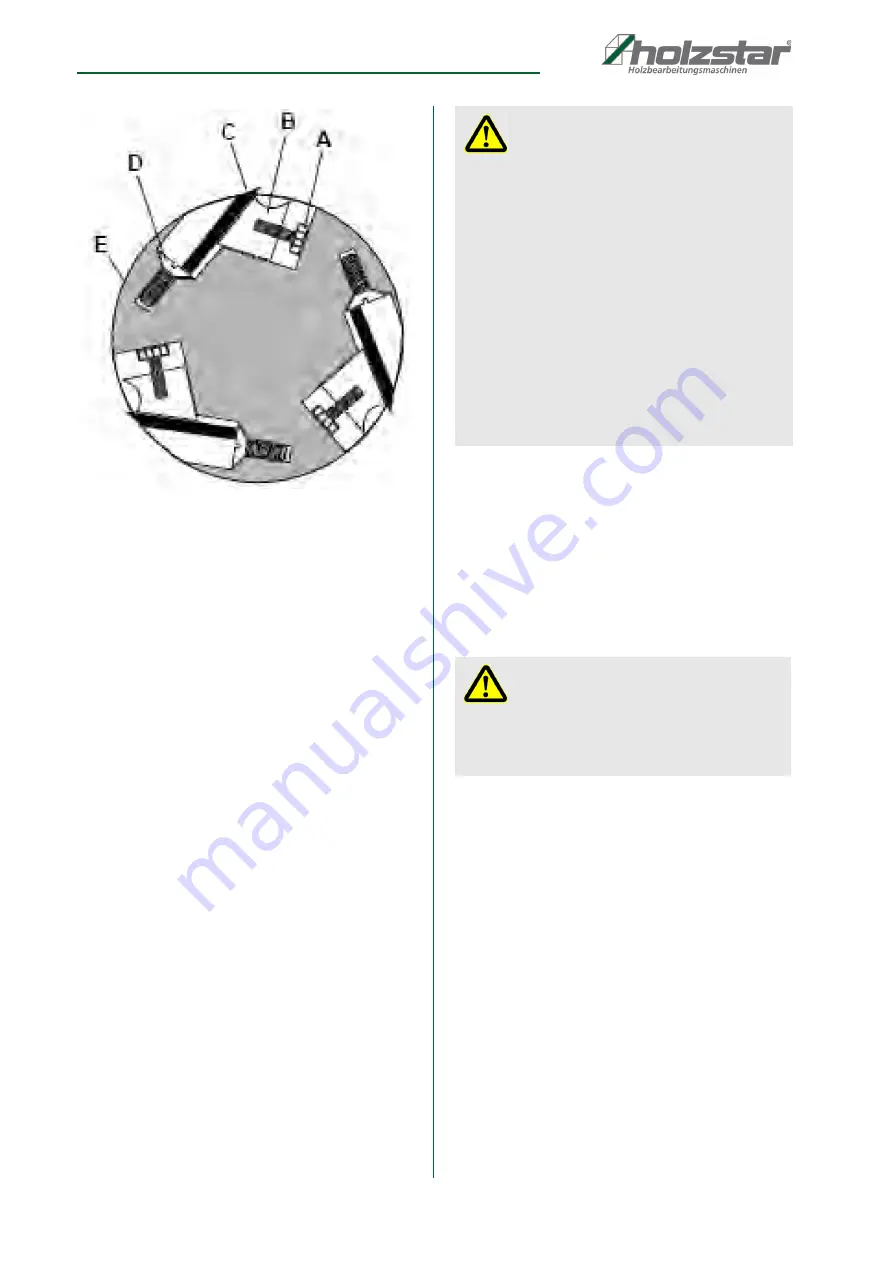

Fig. 15: Cutter head cross-section

Step 6: Note the position of the knife blade with respect

to the straight edge, then move the straight

edge to the other side of the table and again

note the position of the knife blade with respect

to the straight edge. Blade number one must be

at the same height at each end and must also

be at the same height as the outfeed table (bot-

tom of straight edge). If this is not the case, ad-

justment is required as follows:

Step 6.1: Slightly loosen five gib lock screws (Pos. A,

Fig. 14) by turning into the lock bar (Pos. B,

Fig. 14), clockwise as viewed from the infeed

table (Pos. G, Fig. 14).

Step 7: Adjust the knife height by turning jack screws

(Pos. D, Fig. 14) upon which the knives rest. To

lower the knife, turn the screw clockwise. To

raise, turn the screw counterclockwise.

Step 8: When the knife is at the proper height, alterna-

tely tighten the five gib lock screws (Pos. A,

Fig. 14).

Step 9: Repeat steps 4 – 8 for knives two and three.

D

8.2.3 Replacement of cutting knives

Disconnect machine from power source before making

any adjustments. Failure to comply may cause serious

injury.

Step 1: Disconnect machine from the power source.

Step 2: Remove the cutter head guard (Pos. B, Fig. 9).

Step 3: Turn all five screws (Pos. A, Fig. 14 and Fig. 15)

into the lock bar (Pos. B, Fig. 14 and Fig. 15) by

turning in a clockwise direction as viewed from

the infeed table (Pos. G, Fig. 14 and Fig. 15).

Step 4: Carefully remove the cutter knife (Pos. C, Fig. 14

and Fig. 15) and lock bar (Pos. B, Fig. 14 and

Fig. 15).

Step 5: Repeat for remaining two knives.

Step 6: Thoroughly clean all surfaces of the cutter head,

knife slots and lock bars of any dust or debris.

Step 7: Insert replacement knife (Pos. C, Fig. 15) into the

knife slot, making sure it faces the proper direction.

Step 8: Insert lock bar (Pos. B, Fig. 15) and tighten just

enough to hold in place.

Step 9: Repeat steps for other two knives.

ATTENTION!

- For workpieces with different thicknesses, first ma-

chine the stronger side (risk of wedging).

- Divide greater material removal into individual in-

feed steps.

- If wedging occurs, reduce infeed.

- Clean the worktable regularly.

- Make sure that the workpieces are free of resin or

dirt.

- Do not treat the worktable with lubricating oil or

grease.

- Use roller supports or extensions for long work-

pieces.

- Always machine workpieces to their full length.

- Do not machine bent or deformed workpieces.

DANGER!

Cutter head knives are dangerously sharp! Use

extreme caution when inspecting, removing, shar-

pening or replacing knives into the cutter head. Fai-

lure to comply may cause serious injury

Summary of Contents for 5904026

Page 57: ...Notes ADH Series Version 1 02 57 15 Notes ...

Page 58: ...www holzstar de ...