22

ADH-Series | Version 1.02

Operation

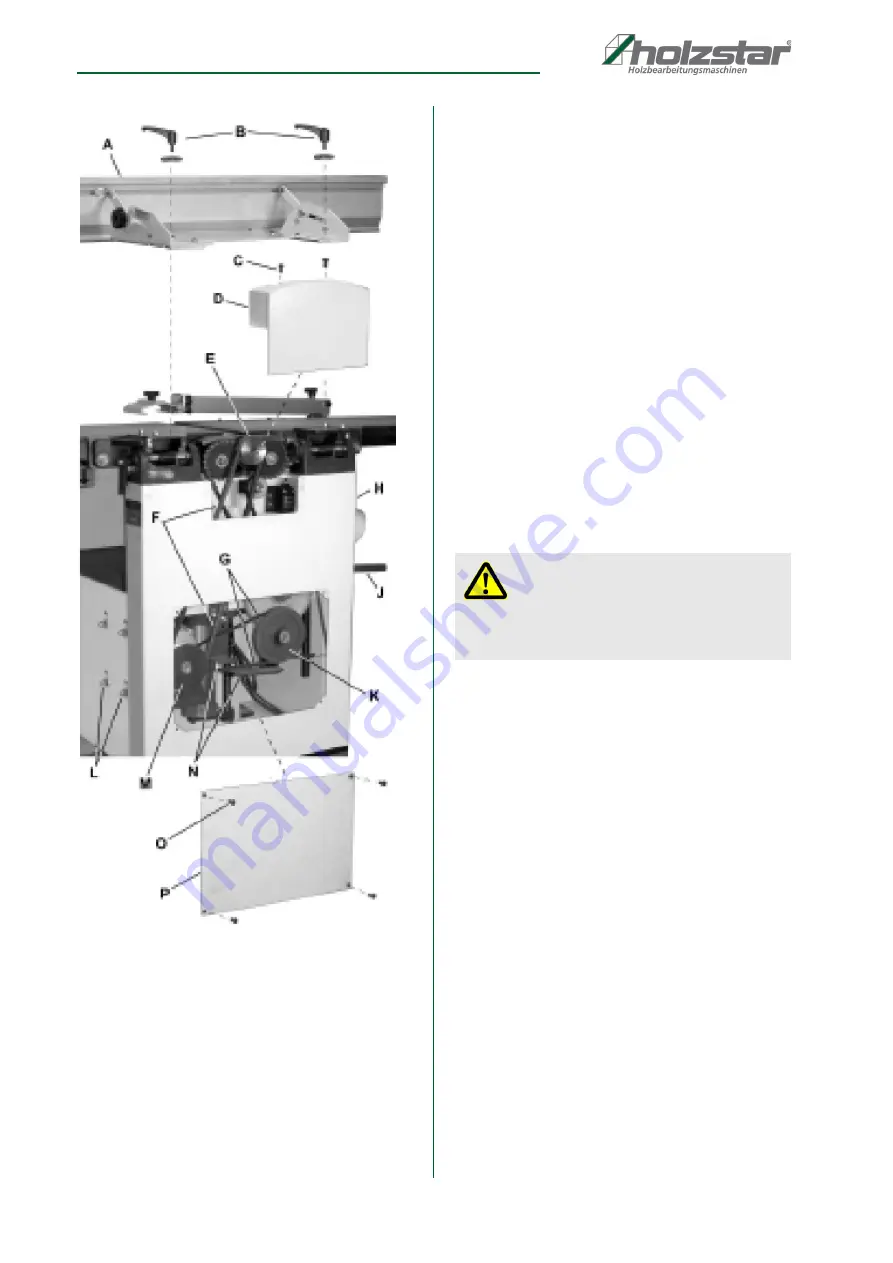

Fig. 16: Belt replacement

Concluding Steps

Step 11: Replace the cutter head drive belt (Pos. F, Fig.

16) by looping it around the cutter head pulley

(Pos. E, Fig. 16), then the larger (outside) motor

pulley (Pos. M, Fig. 16).

Step 12: Slide the motor so the mounting screws (Pos. L,

Fig. 16) rest back in the vertical slot openings,

then tighten the mounting screws.

Step 13: Replace the lower back panel (Pos. P, Fig. 16)

and secure with four button head socket

screws (Pos. O, Fig. 16).

Step 14: Replace the upper back panel (Pos. D, Fig. 16)

and secure with two button head socket screws

(Pos. C, Fig. 16).

Step 14: Replace the jointer fence assembly (Pos. A,

Fig. 16) and secure with two lock handle as-

semblies (Pos. B, Fig. 16).

8.2.5 Adjustment of the planer table

Checking planer table parallel to cutter head

The planer table is set parallel to the cutter head at the

factory and no further adjustment should be needed. If

your machine is planing a taper, first check to see if the

knives are properly adjusted in the cutter head (see

„Setting cutter head knives“) and make adjustments if

necessary.

After the knives are confirmed to be properly set, check

to see if the work table is set parallel to the cutter head

as follows.

Step 1: Disconnect machine from power source.

Step 2: Rotate the cutter head such that one of the knife

blades (Pos. A, Fig. 17) is at the 6 o'clock posi-

tion.

Step 3: Place a gauge block (Pos. B, Fig. 18) or another

measuring device on the work table (Pos. C,

Fig. 18) at one edge (Pos. D, Fig. 18) directly un-

der the cutter head.

DANGER!

Disconnect machine from power source before

making any adjustments.

Failure to comply may cause serious injury.

Summary of Contents for 5904026

Page 57: ...Notes ADH Series Version 1 02 57 15 Notes ...

Page 58: ...www holzstar de ...