Malfunctions, their potential causes and remedies

SAA Series | Version 1.06

13

10 Malfunctions, their potential causes

and remedies

11 Disposal, reusing used machines

To protect the environment make sure that all machine

components are exclusively disposed of as intended and

legally permitted.

11.1 Decommissioning

Disused machines must be decommissioned immedi

-

ately to prevent unintended use at a later point and put

-

ting the environment or persons at risk.

Step 1: Disposable environmental in hazardous opera

-

ting materials from the end of life device.

Step 2: If necessary, disassemble the machine into as

-

semblies and components that are easy to

handle and suitable for recycling.

Step 3: Dispose of the machine components and proces

-

sing materials using the intended disposal me

-

thods.

11.2 Disposal of electrical equipment

Electrical devices contain a variety of recycling-capable

materials and also environmentally hazardous compo

-

nents.

Separate these components and dispose of them appro

-

priately. In case of doubt, contact your local waste dispo

-

sal authority. Consult a specialist disposal agent for recy

-

cling if needed.

11.3 Disposing of lubricants

Lubricant manufacturers provide disposal information for

the lubricants used. If necessary, request productspeci

-

fic data sheets.

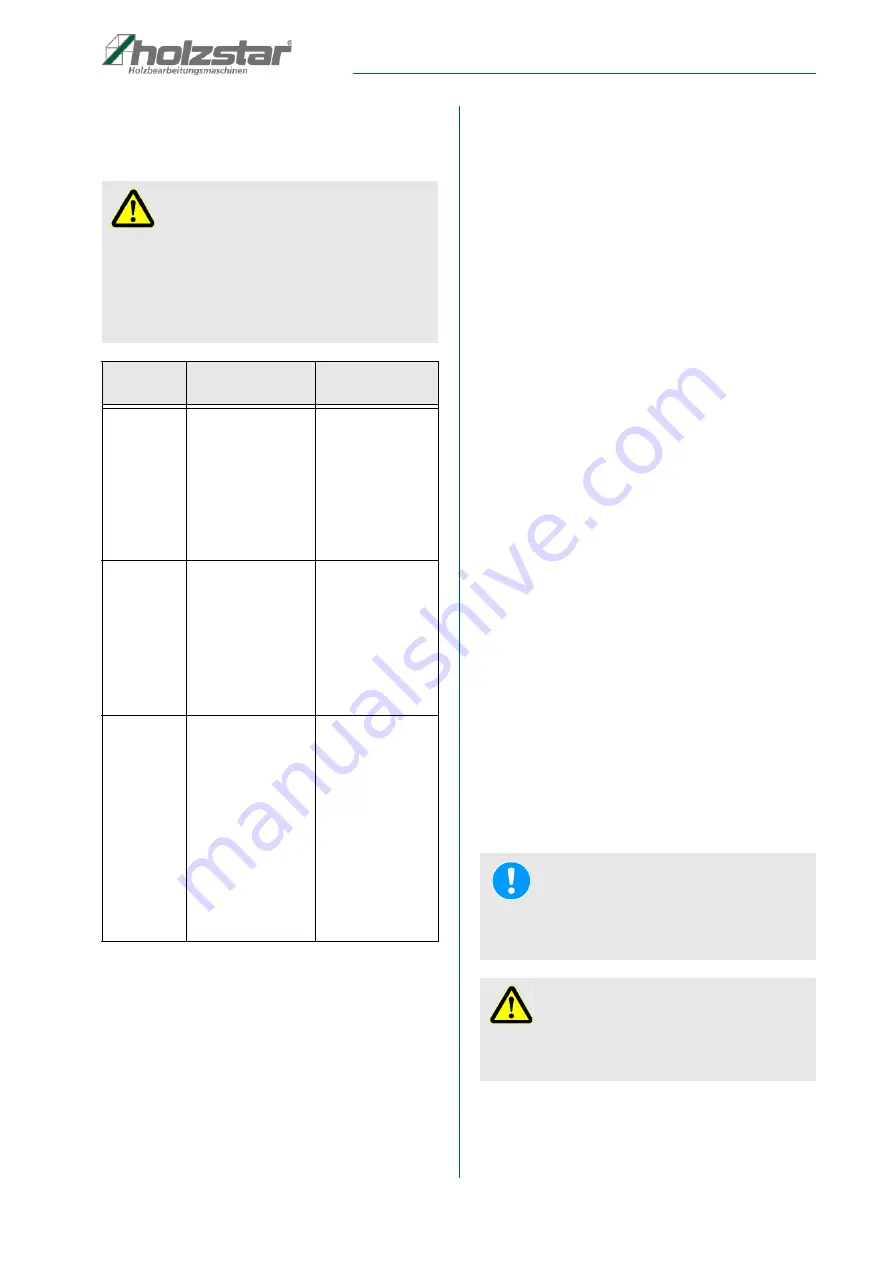

IMPORTANT!

If one of the following malfunctions occurs, immedi

-

ately stop working with the machine. Before you start

troubleshooting, turn off the machine and unplug the

power plug. Failure to do so can lead to serious

injury. All repairs or replacement work may be perfor

-

med by qualified and trained expert staff only.

Malfunc

-

tion

Possible cause

Remedy

Machine

does not

start

1. Power plug is

not plugged in.

2. Power supply

cables defec

-

tive.

3. Switch defec

-

tive

4. Motor defective

1. Plug in the po

-

wer plug.

2./3./4.

Call a service

technician

Strong

vibrations

1. Loose compo

-

nent

2. Motor support is

brocked.

3. Motor bearing is

used up

1. Check all

connections,

tighten bolts

and nuts.

2. Replace the

motor support

3. Replace the

motor bearding

Poor

extraction

1. Dust container

is full

2. Filter is blocked

3. The Extraction

Unit is under-

sized

4. The extraction

line is too long

1. Empty the dust

container.

2. Clean the filter.

3. Use The ex

-

traction line

with Ø larger

than100 mm.

4. Set the Extrac

-

tion Unit near

on the wood

-

working

machine

NOTE!

Old chill lubricant emulsions and oils should not be

mixed with each other, because only not mixed waste

oils are usable without pretreatment.

ATTENTION!

Please take care for an environmentally sound dispo

-

sal of the used coolants and lubricants. Follow the

disposal tips of your municipal disposal companies.

Summary of Contents for 5922201

Page 20: ...www holzstar de ...