Operation

DH-Series | Version 1.01

15

- Observe all safety and danger notices on the ma-

chine.

- If larger workpieces are to be handled in such a

way that the table top must be tilted, a table exten-

sion or a special lift truck (additional accessory)

must be used.

- Pay attention to the direction of rotation of the tool

and the correct entry direction of the workpiece.

- Cloths, cables and similar objects must not be

placed on the work surface when the machine is in

operation.

- After prolonged operation of the machine, external

metal parts and equipment may become hot.

- Support the workpiece sufficiently.

- Use additional tools such as horizontal holders to

machine smaller workpieces.

8.1 Thickness planing of workpiece

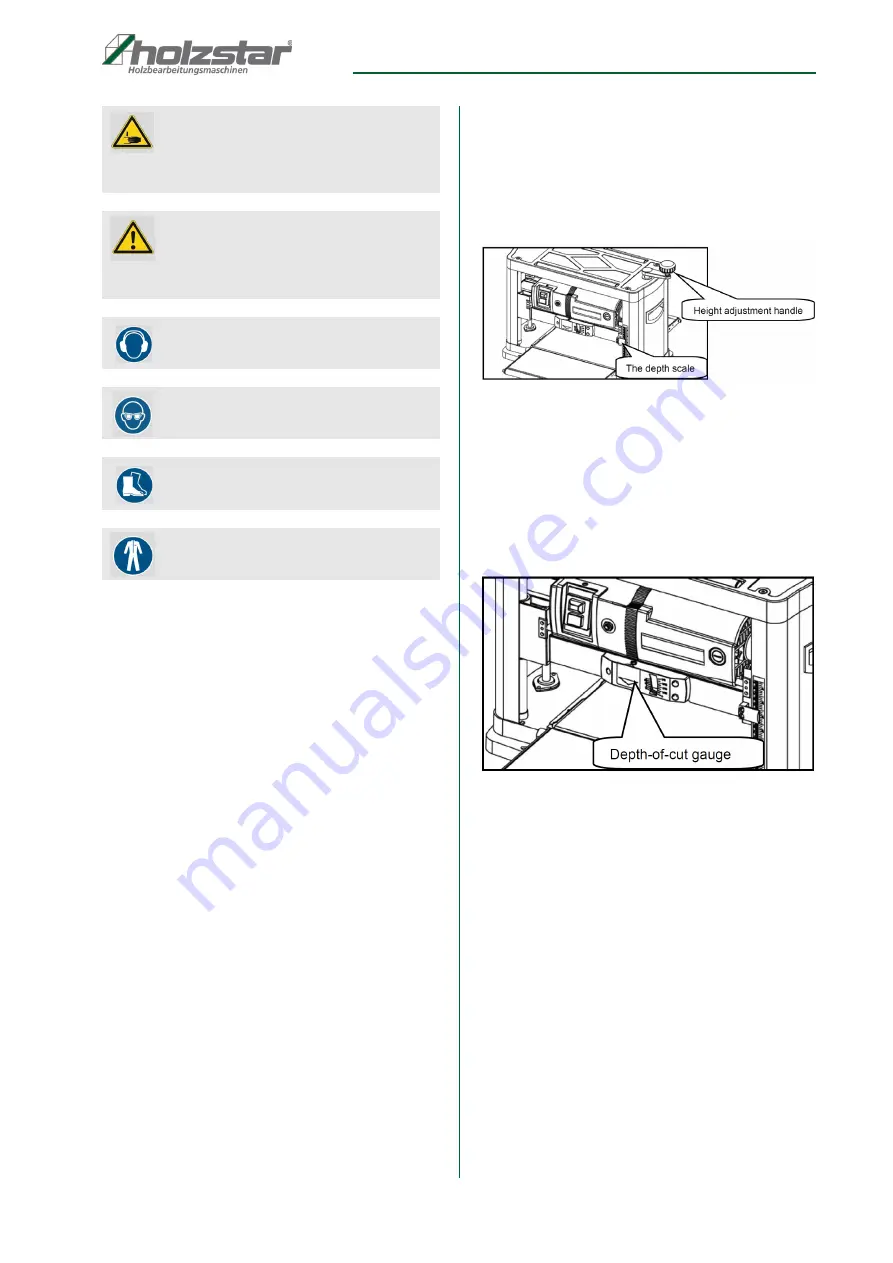

Step 1: Rotate the height adjustment handle for raising

or lowering the cutterhead. The depth scale

shows the height of cutterhead above the main

table.

Fig. 16: Height adjustment of the planer

A spring loaded depth-of-cut gauge is attached to front

of roller case. The pointer on depth-of-cut gauge ac-

curately displays the depth-of-cut per pass when work-

piece is positioned below the gauge.

Step 1: Cranking the handle moves the roller case down

and the pointer shows the desired depth-of-cut.

Fig. 17: Depth-of-cut gauge

Step 2: Adjust the depth of cut to make an initial light

(0.5mm) cut.

Note that one revolution of the height adjustment

handle is equivalent to 2 mm depth of cut.

Step 3: Switch on the machine and wait until the motor

has reached full speed.

Step 4: Press the board against the in-feed table and

feed it into the machine.

Step 5: Release the board when the machine starts to

cut and let the board feed into the machine au-

tomatically.

CAUTION!

Risk of crushing!

Improper work on the machine may result in injury to

the upper limbs.

ATTENTION!

Before commissioning, check the electrical connec-

tion, cables and contacts.

Wear hear protection!

Use protective goggles!

Wear safety boots!

Wear protective clothes!

Höheneinstellungskurbel

Tiefenskala

Messgerät für die Schnitttiefe