Safety

DH-Series | Version 1.01

5

Operating staff:

Operating staff has undergone an induction by the ope-

rator about the entrusted tasks and potential hazards

resulting from improper behaviour. Tasks which go

beyond normal operation may only be carried out by the

operator if they are listed in the operation manual and

the operator has made him/herself familiar with them.

Qualified electrician:

Due to the electrician's specialised training, know-how,

experience and knowledge of pertinent standards and

regulations the electrician is in a position to work on the

electrical systems, and autonomously identify and avoid

potential hazards.

Specialist staff:

As a result of specialist training, expertise, experience

and skills in terms of the relevant standards and regula-

tions, specialist staff is able to complete the tasks they

are entrusted with and independently identify hazards

and avert risks.

Manufacturer:

Certain work must be carried out by manufacturer spe-

cialist staff only. Other staff is not permitted to carry out

this work. Contact our customer service to have the work

carried out.

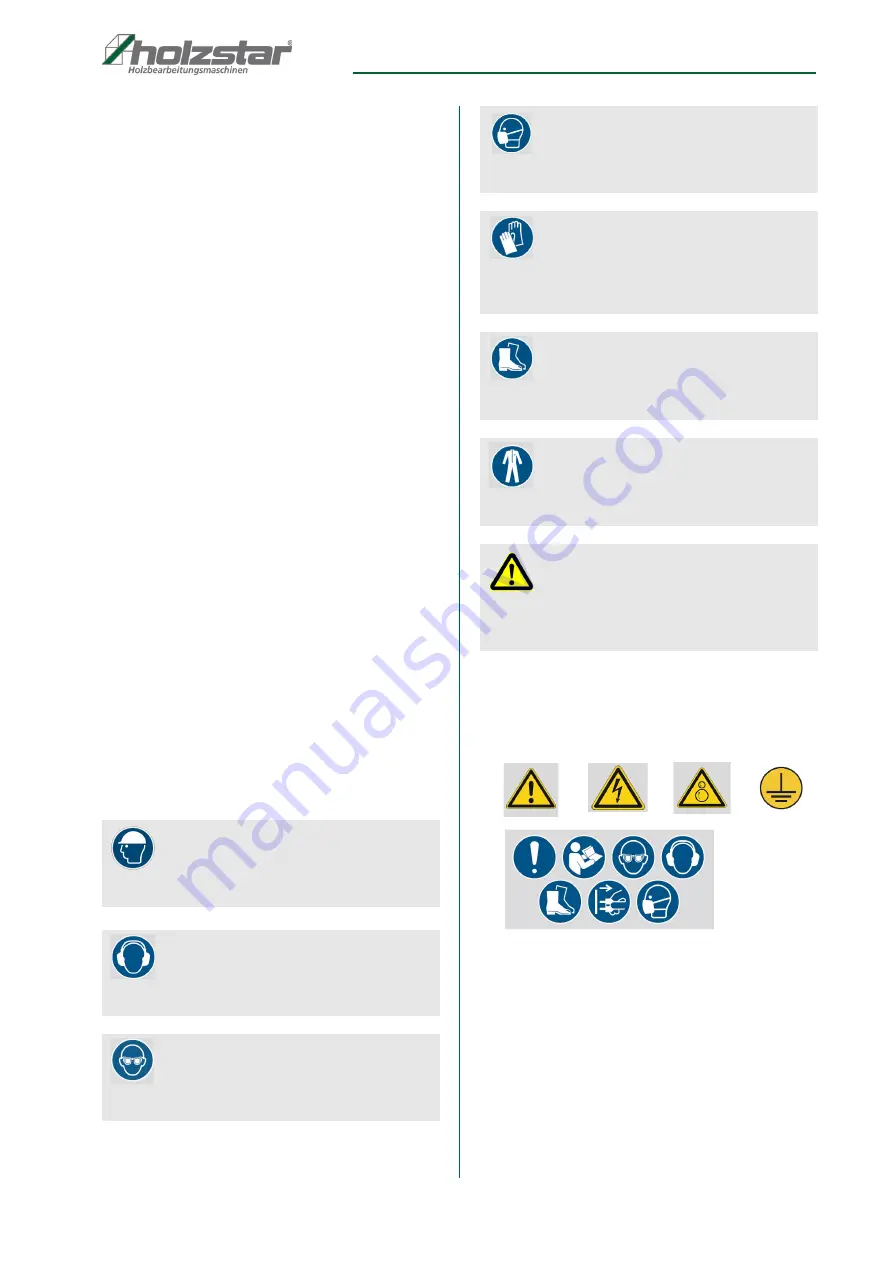

2.4 Personal protective equipment

Personal protective equipment is intended to protect the

health and safety of persons at work. Staff must wear the

personal protective equipment indicated in individual

sections of these operating instructions when carrying

out the different tasks on the machine.

The personal protective equipment is described in the

following section:

2.5 Safety labels on the planer

The following safety labels and instructions are attached

to the planer (Fig. 1) and must be observed.t

Fig. 1: Safety labels

1 Warning of danger | 2 Warning of dangerous electrical

voltage | 3 Warning of danger of entanglement I 4 Ground sym-

bol l | 5 Mandatory signs

If safety labels on the machine are damaged or missing,

this can cause errors, personal injury and material

damage. The safety symbols attached to the machine

must not be removed. Damaged safety symbols must

be replaced immediately.

As soon as the signs are not clearly visible and compre-

hensible at first glance, the machine must be stopped

until new signs have been attached.

Head protection

The industrial helmet protects the head against fal-

ling objects and bumping into stationary objects.

Hearing protection

The hearing protection protects the ears against

damages of hearing due to noise.

Eye protection

Protective glasses protect the eyes against pro-

jected parts and splashes of liquid.

Protective dust-mask

The dust protection mask protects the respiratory

tract from wood chips and wood dust.

Protective gloves

The protective gloves provide protection for the

hands against sharp-edged components, as well as

against friction, abrasions or deeper injuries.

Safety boots

The safety boots protect the feet against crushes, fall-

ing parts and slipping over on slippery underground.

Protective clothes

Protective work clothing means tight-fitting clothing

with low tear resistance.

CAUTION!

Impurged, possibly contaminated body protection

products can cause illnesses.

Clean them after each use and once a week.

2

3

1

5

4