Operation

KGZ 305 E | Version 1.09 | EN

9

8.1 Pre-adjustment

8.1.1 Setting the mitre angle (mitre cut)

In addition to the stepless adjustment of the mitre angle,

there are fixed angle positions at 0°, 15°, 22.5°, 30° and

45°.

The angle for the mitre cut is set on the angle scale of the

saw table as follows:

Step 1: Loosen the table lock. To do this, turn the adju-

sting knob for the table arrest open (Fig. 8).

Fig. 8: Setting the mitre angle

Step 2: Use the setting mark and the angle scale with

markings to set the desired mitre angle in 1°

steps. There are snap-in points for the angles 0°,

15°, 22.5°, 30° and 45°.

Step 3: Lock the table in the set angle position by turning

the knob.

8.1.2 Inclination of the saw head (inclined cut)

The saw head can be tilted up to 45° to the left and right

(see Fig. 10). Snap-in points exist for 15° and 30° in both

directions. Proceed as follows for the inclined position:

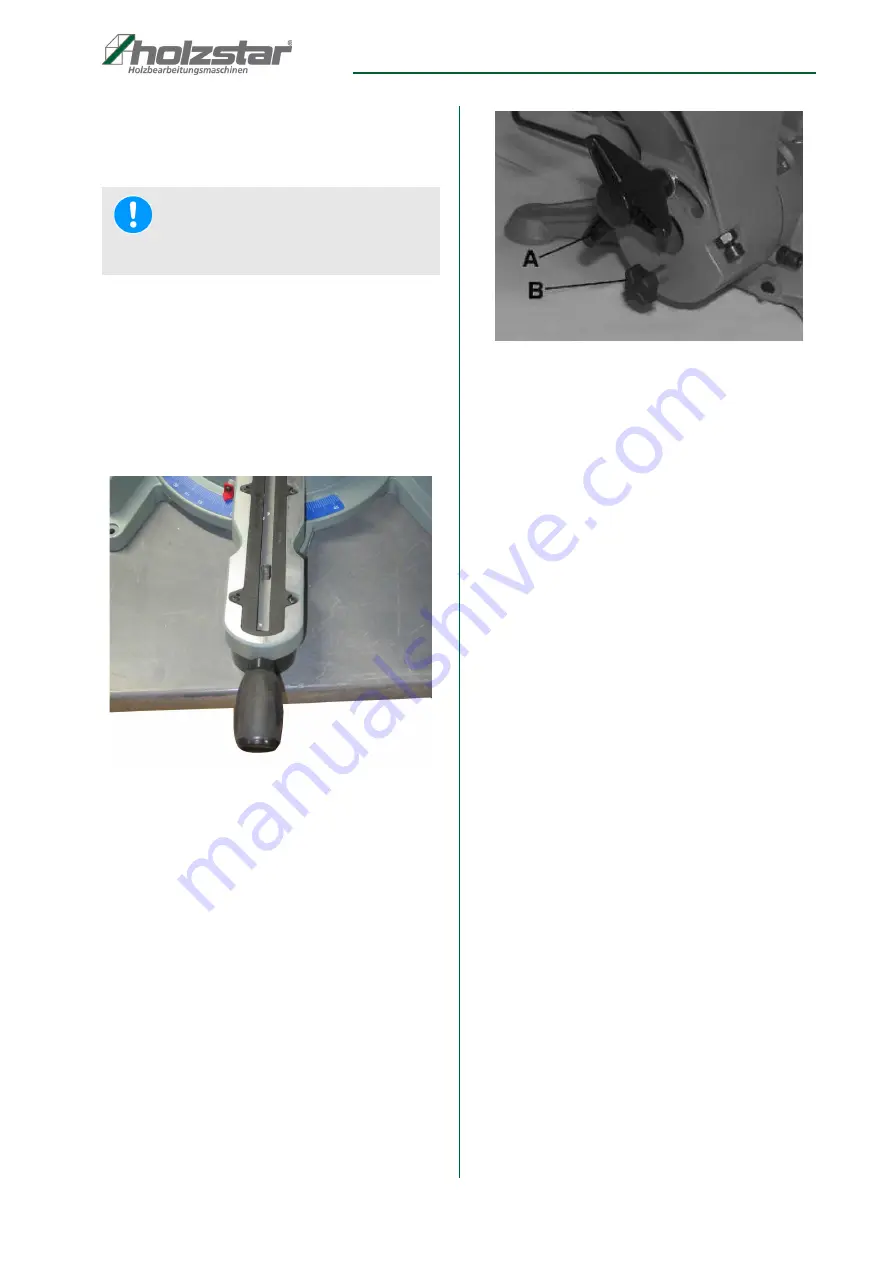

Fig. 9: Adjusting the angle of inclination

Inclined position - stepless

Step 1: Hold the saw head by the saw head retaining

handle.

Step 2: Loosen the locking screw (A, Fig. 9) and pull the

locking knob (B).

Step 3: Tilt the saw head to the left or right by the desired

angle. The angle scale assigned to the tilt posi-

tion with markings in 1° increments is located at

the rear end of the table.

Step 4: Loosen the locking knob and tighten the locking

screw.

Inclination - in 15° steps

Step 1: Hold the saw head by the saw head retaining

handle.

Step 2: Loosen the locking screw.

Step 3: Pull the locking knob in 15° increments to deacti-

vate locking.

Step 4: Tilt the saw head to the desired 15° step. The

angle scale at the rear end of the table, which is

assigned to the oblique position, is provided with

markings for the 15° steps.

Step 5: Release the locking knob and move the saw

head a few degrees until the locking knob au-

dibly engages in the 15° step.

Step 6: Tighten the locking screw.

Step 7: Tilt the locking knob and move the saw head a

few degrees.

NOTE!

Select a mitre angle of 0° for a vertical cross-section

(90° section)!