Operation

SAA 901 | Version 1.01

13

9 Operation

9.1 Turn on

- Check whether the suction hose (11) is securely

connected to the extraction unit and to the ex-

traction adapter of the woodworking machine.

- Check that the Dustbags are well secured.

- Turn on the Extraction system by pressing the

Grenn „I“ Button.

- Switch on the woodworking machine.

9.2 Turn off

- Switch off the woodworking machine.

- Switch off the suction system by pressing the red

"O" button or by pressing the emergency stop

button.

9.3 Emptying the chip-collecting bag

- Regularly inspect and empty the chip collecting

bag (6).

- Hold the filled chip collection bag with one hand.

- Open the quick-release device (5).

- Remove the bag and dispose of the contents in an

environmentally sound manner.

- Reattach the bag to the holder and secure with the

quick-release device (5).

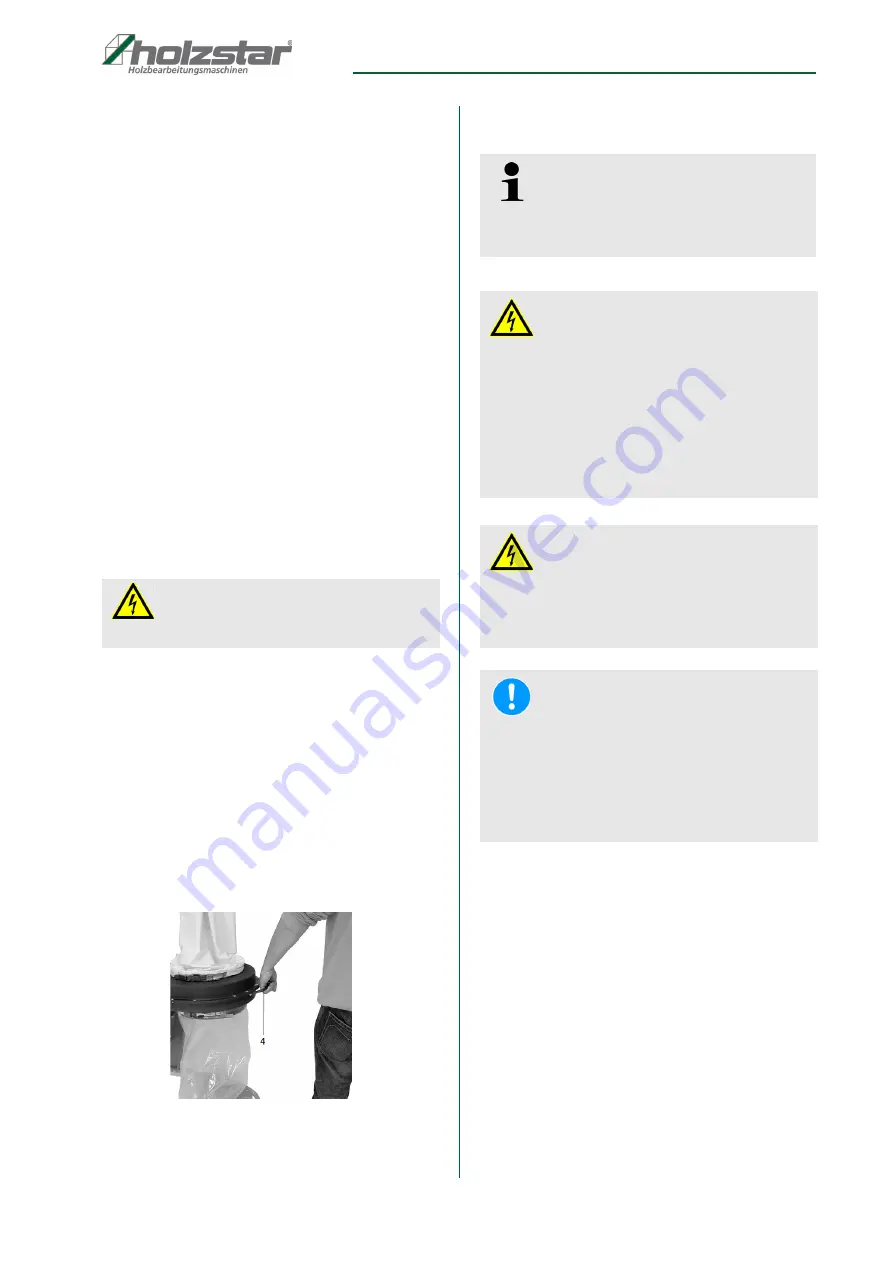

9.4 Transport of the Exhaust system

The exhaust system has a standard chassis. To trans-

port the exhaust system, lift slightly on the transport han-

dle (4) (Fig.14) and drive to the desired location.

Fig. 14: Chassis

10 Maintenance and Service

ATTENTION!

Pull the Power Plug out !

Tips and recommendations

The Chip Extraction Unit is constructed for efficient

operating. To guarantee a long life the servicing

aspects are to be carried out regularly.

ATTENTION!

Danger to life due to electrical shock!

Danger of live through electric shock by contact with

live power components!

- The Chip Extraction Unit may connected only from

Qualified electrician.

- Repairs on the electrical system must execute only

from Qualified electrician.

- Switch off the machine and pull the plug out before

starting any cleaning or maintenance work.

WARNING!

Risk from inadequately qualified persons!

Inadequately qualified persons are unable to assess

the risks when handling the machine, thus putting

themselves and others at risk of severe injuries.

All work must be carried out by qualified persons only.

NOTE!

After servicing, repair or cleaning please check

whether all protective devices are mounted properly

again, and no more tools are left inside the machine.

Damaged safety devices, machine parts and coun-

ters must be exchanged in accordance with the

requirements by an approved professional

workshop.