14

SAA 901 | Version 1.01

Malfunctions, their potential causes and remedies

Daily Service

- -Clean the machine after every use.

- -Replace damaged security devices immediately.

Weekly Service

- Clean the machine regularly with a humid cloth

and some soft soap. Don´t use cleaning agents or

solvents; these could damage the plastic parts of

the machine. Take care that no water can get into

the machine.

- Keep safety devices, air openings and engine ca-

binet free of dust and dirt. Clean the machine with

a clean cloth or blow it out with air pressure at a

low pressure.

- A dust protection mask is to be worn while chan-

ging and emptying the dust bag.

Monthly Service

- Control fixing bolts of the machine.

Service after 6 month

- Check electric security and safety devices

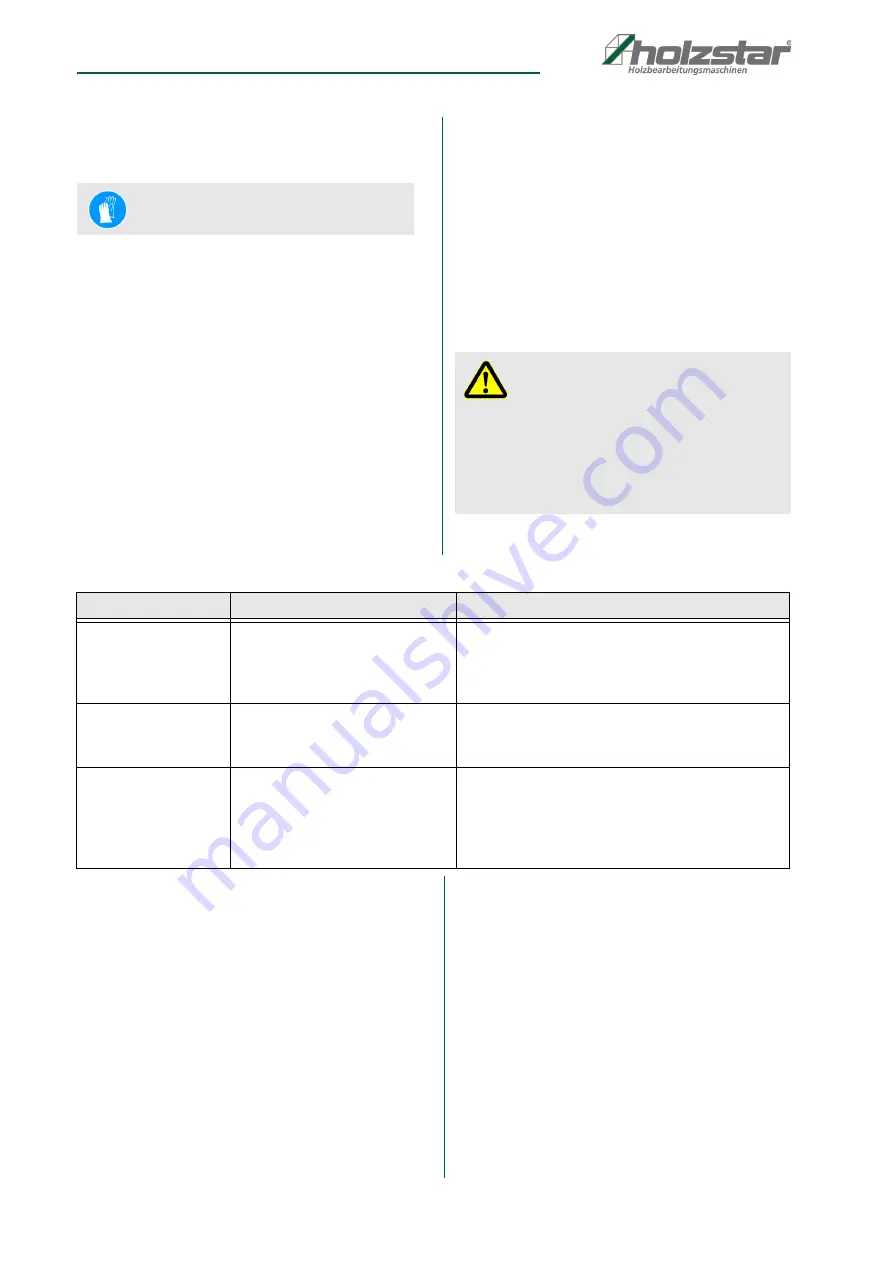

11 Malfunctions, their potential causes

and remedies

12 Disposal, reusing used machines

To protect the environment make sure that all machine

components are exclusively disposed of as intended

and legally permitted.

12.1 Decommissioning

Disused machines must be decommissioned immedi-

ately to prevent unintended use at a later point and put-

ting the environment or persons at risk.

- Disposable environmental in hazardous

operating materials from the end of life device.

- If necessary, disassemble the machine into

assemblies and components that are easy to

handle and suitable for recycling.

- Dispose of the machine components andproces-

sing materials using the intended disposal

methods.

Wear the safety gloves!

IMPORTANT!

If one of the following malfunctions occurs, immedi-

ately stop working with the machine. Before you start

troubleshooting, turn off the machine and unplug the

power plug. Failure to do so can lead to serious

injury. All repairs or replacement work may be per-

formed by qualified and trained expert staff only.

Malfunction

Possible cause

Remedy

Machine does not

start

1. Power plug is not plugged in.

2. Power supply cables defective.

3. Switch defective

4. Motor defective

1. Plug in the power plug

2. Call a service technician

3. Call a service technician

4. Call a service technician

Strong vibrations

1. Loose component

2. Motor support is brocked.

3. Motor bearing is used up

1. Check all connections, tighten bolts and nuts.

2. Replace the motor support

3. Replace the motor bearding

Poor extraction

1. Dust container is full

2. Filter is blocked

3. The Extraction Unit is under si-

zed

4. The extraction line is too long

1. Empty the dust container.

2. Clean the filter.

3. Use The extraction line with Ø larger than100 mm.

4. Set the Extraction Unit near on the woodworking

machine