3

HEALTH AND SAFETY GUIDANCE NOTES

5. Ensure the tool is disconnected from power

supply before servicing.

6. Ensure that when switching on (e.g. after

servicing) no tools or loose parts are left on or

in the tool.

7. Turn power off if the tool is not used.

Cutting hazard, even with the cutting tool at

standstill!

Wear gloves when changing cutting tools.

Risk of kickback (work-piece is caught by the

saw blade and thrown against the operator):

1. Always work with a properly set riving knife.

2. Do not jam work-piece.

3. Cut thin or thin-walled work-piece only with

fine-toothed saw blades. Always use sharp

saw blades.

4. If in doubt, check work-piece for inclusion of

foreign matter (e.g. nails or screws).

5. Cut only stock of dimensions that allow for sate

and secure holding while cutting.

6. Never cut several work-pieces at the same

time – and also no bundles containing several

individual pieces. Risk of personal injury if

individual pieces are caught by the saw blade

uncontrolled.

7. When cutting round stock, use a suitable jig to

prevent the work-piece from turning.

Drawing-in/trapping hazard!

Ensure that no parts of the body or clothing can be

caught and drawn in by rotating components (no

neckties, no loose fitting clothes; contain long hair

with hairnet).

Never cut work-pieces containing the following

materials:

-

ropes

-

strings

-

cords

-

cables

-

wires

Hazard generated by insuffi-cient personal

protection gear!

- Wear hearing protection.

- Wear safety glasses.

- Wear dust mask.

- Wear suitable work clothes. When working

outdoors wearing of non-slip shoes is

recommended.

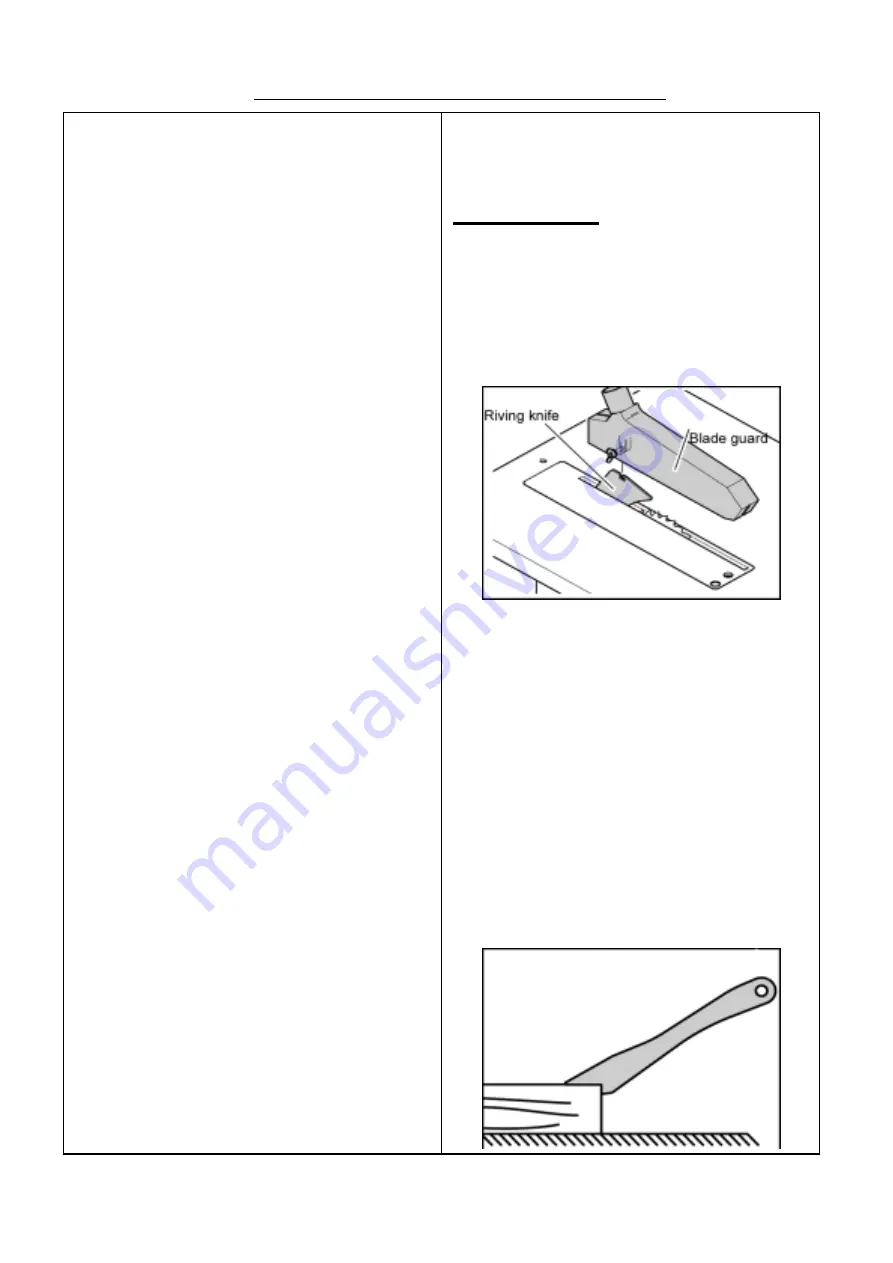

Safety devices

Riving knife

The riving knife prevents the work-piece from being

caught by the rising teeth of the saw blade and

being thrown against the operator.

Always have the riving knife installed during

operation.

Blade guard

The blade guard protects against unintentional

contact with the saw blade.

Push stick

The push stick serves as an extension of the hand

and protects against accidental contact with the

saw blade.

Always use the push stick if the distance between

saw blade and rip fence is less than 120 mm.

Guide the push stick at an angle of 20 °… 30 °

against the saw table's surface.

Replace the push stick if damaged.