EngliSH | 29

5.4. Preparatory Work

The machine has been designed and assembled accord-

ing to the state of the art, so that it works reliably for a

long time under normal operating conditions. However, a

prerequisite for this is that you follow all the requirements

and instructions.

Please check the following points:

•

Cable guidance – no loops, slightly taught

•

Check the temperature of the conveying medium and

immersion depth

•

If a hose is used on the discharge side, this is to be

rinsed through with clean water before it is used, so

that there are no deposits or blockages

•

For a wet setup, the pump sump is to be cleaned

•

The pipework system on the discharge side and suc-

tion side is to be cleaned, and all gate valves are to

be opened.

•

The pump housing must be ventilated, i.e. it must be

completely filled with the medium and it must not

contain any more air. The ventilation may be done

by suitable ventilation equipment in the system or,

if present, by bleeder screws on the pressure joint.

•

Check the accessories, pipework system and the at-

tachment device for correct, firm seating.

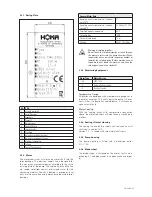

5.5. Electrical System

When laying and selecting the electrical lines and when

connecting the motor, the relevant local and VDE regula-

tions are to be followed. The motor must be protected by

a motor overload switch.

Danger due to electricity!

There is danger of death due to improper handling

of electricity!

5.6. Direction of Rotation

For 1Ph motors, checking the direction of rotation is not

necessary, as it can always run with the correct direction

of rotation.

5.7. Type of Activation

Types of Activation with Plug

Plug the plug in the socket provided for this purpose.

Pump runs directly, if the sensor is triggered.

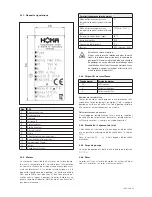

5.7.1. After Activating

The rated current is briefly exceeded during the starting

process. After this process has finished, the operating

current should no longer exceed the rated current. If the

motor does not start immediately after switching on, it

must be shut down immediately. Before switching on

again, the pauses must be maintained according to the

technical data. If there is a new fault, the machine must

be shut down again immediately. A new activation pro-

cess must only be started after troubleshooting.

The following points should be checked:

•

Switching frequency and pauses (see Technical Data)

•

Air introduction on admission side, a baffle plate may

have to be attached

•

Minimum water covering, level control, protection

against dry running

•

Quiet running

•

Check for leaks, take any necessary steps according

to the “Maintenance” chapter

6. Maintenance

6.1. General

The pump as well as the entire system must be inspect-

ed and maintained at regular intervals. The interval of the

maintenance is determined by the manufacturer and ap-

plies for the general conditions of use. The manufacturer

must be contacted in the event of aggressive and/or abra-

sive pumped mediums, since the interval could be short-

ened in these cases.

The following points must be noted:

•

The operating instructions must be available to the

maintenance personnel and must be followed. Only

maintenance work and measures listed here must be

carried out.

•

All maintenance work, inspection work and cleaning

work on the machinery and the system must be car-

ried out with due diligence, at a safe working place

and by trained qualified personnel. The required pro-

tective gear must be worn. The machinery must be

disconnected from the power supply for all work.

Unintentional start must be prevented. Furthermore

the respective protective measures according to the

Employers’ Liability Association regulations, BGV/the

Statutory Accident insurance, GUV must be complied

with when working in basins and/or containers.

Ensure that sling gear, ropes and the safety equipment

of the hand winch are technically sound. The work

must only be started when the auxiliary hoisting gear

is technically in order. Failure to carry out these checks

may jeopardize your life!

•

f easily inflammable dissolvers and cleaning materials

are used, open fire, open light as well as smoking are

prohibited.

•

Ensure that the required tools and materials are read-

ily available. Tidiness and cleanness ensure safe and

proper work on the machinery. Remove used clean-

ing materials and tools from the machinery after the

work has been carried out. Keep all materials and

tools in a dedicated place.

•

Service media (such as for example oils, lubricants,

etc.) must be captured in a suitable container and

must be disposed of according to the regulation

75/439/EEC and writ §5a, 5b abfG, Waste Avoidance

and Management Act). Respective protective cloth-

ing must be worn when carrying out cleaning work

and maintenance work. This must be disposed of ac-

cording to waste catalogue TA 524 02 and EC direc-

tive 91/689/EEC. Only lubricants recommended by

the manufacturer must be used. Oils and lubricants

must not be mixed. Only use manufacturer’s original

parts.

Summary of Contents for C260WA

Page 17: ...DEUTSCH 17 Notizen Notes ...

Page 63: ...63 Notizen Notes ...

Page 64: ...64 Notizen Notes ...

Page 65: ...65 Notizen Notes ...

Page 70: ...70 ...