42

•

After storage longer than one year the oil of motor and, if necessary the gear have to be changed.

This is also necessary if the product never had run (natural deterioration of mineral oil).

Before start-up, the filling levels (oil, cooling fluid etc.) of the individual products should be checked and

topped up if required. Please refer to the machine data sheet for specifications on filling. Damaged

coatings should be repaired immediately. Only a coating that is completely intact fulfills the criteria for

intended usage!

If these rules are observed, your product can be stored for a longer period. Please remember that elastomer parts

and coatings become brittle naturally. If the product is to be stored for longer than 6 months, we recommend

checking these parts and replacing them as necessary. Please consult the manufacturer.

4.4. Returning to the supplier

Products which are delivered to the plant must be clean and correctly packaged. In this context, clean means that

impurities have been removed and decontaminated if it has been used with materials which are hazardous to

health. The packaging must protect the product against damage. Please contact the manufacturer before

returning!

5. Installation and Start-Up

5.1 General

In order to prevent damage to the mixer or serious injury during installation the following points must be observed:

•

Installation work may only be carried out by qualified persons. The safety instructions must be

followed at all times.

•

The mixer must be inspected for damages before any installation work is carried out.

•

Protect the mixer from frost.

•

The operating area must be laid out for each machine. You must ensure that lifting gear can be

fitted without any trouble, since this is required for assembly and removal of the machine.

•

The maximum bearing capacity must be greater than the weight of the machine, add-on units and

cable.

•

Electric power cables must be laid out in such a way that safe operation and non-problematic

assembly/dismantling are possible at all times.

•

The electric power cables should be fastened properly to the pipes with cable holders or other

suitable equipment. This should prevent loose hanging and damage to the electric power cables.

Depending on the cable length and weight, a cable holder should be fitted every two or three

meters.

•

The structural components and foundations must be of sufficient stability to ensure safe and

functional operation. The operator or supplier is responsible for the provision.

•

Never let the unit run dry.

•

Use defector plates for the pumped fluid intake that air cannot introduce into the pumped liquid. this

will lead to that the pump will run smoothly and is subjected to higher wear and tear.

5.2 Installation

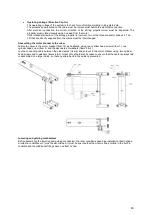

Danger of falling!

Installation work for the mixer and its accessories is performed directly on the edge of the basin.

Carelessness or wearing inappropriate clothing could result in a fall. There is a risk of fatal injury! Take

all necessary safety precautions to prevent this.

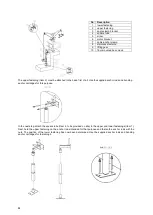

Mixer

The mixer is delivered ready assembled. During installation of the mixer please check the following:

•

Propeller

The propeller must not touch the tank floor or walls in any possible installation position (min. 40 cm

distance).

•

Motor Cable

The cable must not be stretched even when the mixer is completely lowered. The cable should be

positioned with always providing large bending radius in order to prevent breaking.

The connecting cable should be guided as tight as possible towards the top, so it is not caught in the

flow.