55

2 - Media Cooled with External Flush

- This construction requires an external flow of water, typically re-use

water. Applications which require this option are typically heavy slurry or sludge service often found in the

treatment plant. This option routes the externally supplied water into the pumped media. No pump modifications

are required.

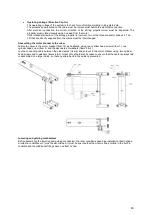

Required Hardware – Mounting a regulating valve, pressure gauge and automated block valve between the

water supply and the upper jacket port is required. The supply valve should be adjusted to allow the supply of

water to exceed pump discharge pressure. This assures a positive flow of water into the pump chamber. The

block valve should be automated to open whenever the pump is operated.

Start Up Requirements – This jacket must be vented at start up. Additional venting may be required if cooling

water supply is interrupted.

3 - External Fluid Cooled

- This option requires an external flow of water like in option 2 above, but is used

where dilution of the pumped product is not desirable. The supply of water is internally isolated from the pumped

media. The water inlet is routed into the jacket’s lowest port and returned out of the highest port. This option does

NOT allow water to enter the pumped media and pump must be ordered from factory this way.

Required Hardware – Mounting a regulating valve, pressure gauge and automated block valve between the

water supply and the upper jacket port is required. The supply valve should be adjusted to allow for a good

supply of water to flow through the jacket. The block valve should be automated to open whenever the pump

is operated.

Start Up Requirements – This jacket must be vented at start up. Additional venting should not be required.

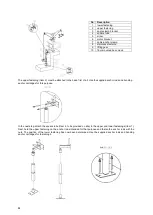

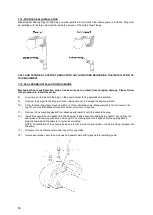

Vent Valve Installation

HOMA dry pit pumps are supplied with a valve and fitting that must be installed and maintained to ensure the

proper performance of these pumps.

The opening for this valve is located on the base of the motor cap near the mounting screws. The pump is

shipped with a plug installed which must be removed prior to start up.

This opening is a metric straight thread and requires an adapter included with the valve and fitting hardware. It is

also recommended that a length of hose be attached to the valve and routed back to the sump.

Note: Leave vent valve open in wet pit pump application to

prevent air entrapment in jacket.