10 | ENGLISH

5. Installation and initial commissioning

5.1. General

To avoid damage to the lifting unit during installation and

operation, the following points must be observed:

• The installation work must be performed by qualified

personnel, in compliance with safety regulations.

• The pump must be inspected for damage prior to in-

stallation.

• For level controls, pay attention to the minimum wa-

ter coverage.

• Air bubbles in the volute and pipework must be avoid-

ed (by suitable ventilation devices or a slight incline

of the pump).

• Protect the pump from frost.

• The lifting device must have a maximum load capaci-

ty which is greater than the weight of the pump with

attachments and cable.

• The power lines of the pump must be laid in such a

way, that a safe operation and easy assembly/disas-

sembly is ensured.

• The power lines must be fixed properly in the operat-

ing room to prevent the cable from hanging loosely.

Depending on the cable length and weight, a cable

holder must be attached every 2-3 m.

• The foundation/structure must have sufficient

strength for secure and functionally correct fastening

of the pump. The operator is responsible for this.

• Verify low level lockout is functioning.

• Use baffles for the inlet. This prevents air entry into

the pumping medium, which can lead to unfavorable

operating conditions and result in increased wear.

• Do not install more than one check valve into any pip-

ing system or problems will occur.

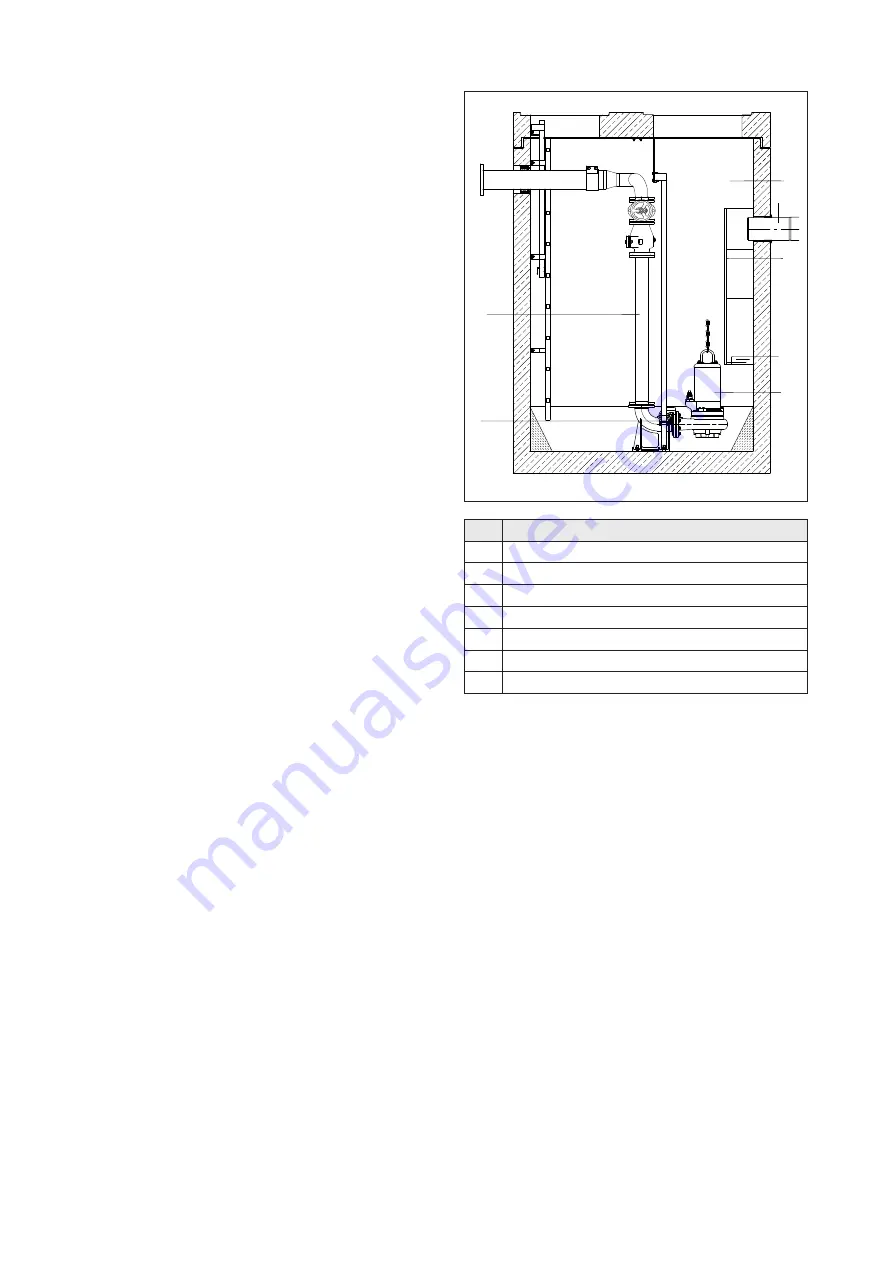

No.

Description

1

Pipe

2

Coupling system

3

Wet well

4

Inlet

5

Baffle plate

6

min. liquid level

7

Pump

External Seal Probe Installation Procedure

If provided, Mechanical Seal Leak Detection probe has

been shipped loose to protect from shipping damage.

Please follow this procedure to install the probe.

1)

Lay pump on its side with the plug on the seal

chamber facing upwards as indicated.

2)

Unscrew the plug with the proper wrench, taking

care not to damage the sealing surface.

3)

Verify that seal chamber oil level is within ¼”

of the indicated value. Measurement is from oil

level to the top of hole. See IOM Manual for seal

chamber oil volume, if required.

4)

Remove the new sealing gasket from package and

install it onto the seal probe plug.

5)

Install the seal probe with gasket into the opening,

taking care not to damage the cable. Then tighten

the seal probe with the proper wrench until snug.

Do not overtighten. Once tight, verify the seal

gasket is properly seated and the cable is not

pinched or twisted.

NOTE: At installation of the seal probe be careful

not to bind the seal probe cord as it is being

installed into the pump.

6)

Lift pump into a vertical position and inspect for

any leaks.

7)

Secure seal probe cable to pump body and power

cable with tyraps before installing pump.