ENGLISH | 11

5.2. Installation

Risk of falling!

When installing the pump and accessories, work is

carried out directly on the water’s edge! Careless-

ness or wearing the wrong shoes can lead to falling.

This is life threatening! Take all safety precautions to

prevent this.

Risque de chute !

Lors de l’installation de la pompe et des accessoires,

les travaux sont effectués directement au bord

de l’eau ! La négligence ou le port de mauvaises

chaussures peuvent entraîner une chute. Ceci pose

un danger de mort ! Prenez toutes les précautions de

sécurité pour éviter cela.

Torque Values:

PUMP MODEL Mounting

Bolts

Anchors

Bolts

Anchors

TORQUE

AUTOCOUPLING

N/A

4

M16

51 Nm / 38 ft lb

RING STAND

4

N/A

5 Nm / 4 ft lb

Notes:

1. Standard anchors are plated steel.

2. Autocoupling systems include qty. 4 M12

anchors for the upper bracket. Torque to 51 Nm

/ 38 ft lb.

3. Anchor bolt holes should be drilled to the actual

diameter of the anchor (M12 anchor requires

12mm diameter hole).

Submerged installation on ring stand

Attach the ring stand (available as an accessory) with

screws to the pump suction nozzle. Mount 90° connec-

tion-elbow or connection loop to the dischargeof the

pump, and mount discharge line. Gate valves and check

valves may need to be installed in accordance with local

regulations. The discharge line must be fitted free of ten-

sion, when using a hose, ensure it is laid kink-free. Secure

the pump by the handle with a cable or chain, and lower it

into the pumping medium. Properly position power cable

and chain so they stay above the pump and cannot enter

the pump suction.

Wet well installation with automatic coupling system

The following instructions apply to the installation of the

original HOMA Autocoupling system:

• Determine the approximate position of the position

of the base elbow and the upper pipe bracket for the

guide tubes, using a plumb bob where necessary.

• Check the correct installation dimensions of the

pump(s) (see dimensional drawings in the appendix).

• Drill mounting holes for the guide rail bracket on the

inside edge of the shaft opening. If this is not possi-

ble due to the space available, the guide rail bracket

can also be mounted in an offset position with a 90°

folded plate on the underside of the shaft cover. Pro-

visionally fasten the guide rail bracket with 2 screws.

• Align the base elbow to the shaft floor, use a plumb

bob from the pipe bracket - the guide tubes must be

exactly perpendicular! Fasten the base elbow to the

wet well floor using anchor bolts. Ensure that the

base elbow is exactly horizontal! If the wet well floor

is uneven, support the bearing surface accordingly.

• Mount the pressure pipes with fittings free of tension

according to the usual mounting principles.

• Insert both guide rails into the eyelets on the base

elbow and cut to size according to the position of the

guide rail bracket. Partially unscrew the guide rails

bracket, insert them into the guide rails and fasten

the bracket. The guide rails must be positioned with

no play at all, otherwise vibration will occur during op-

eration of the pump.

• Clean the wet well of any solid material (debris,

stones, etc.) before commissioning.

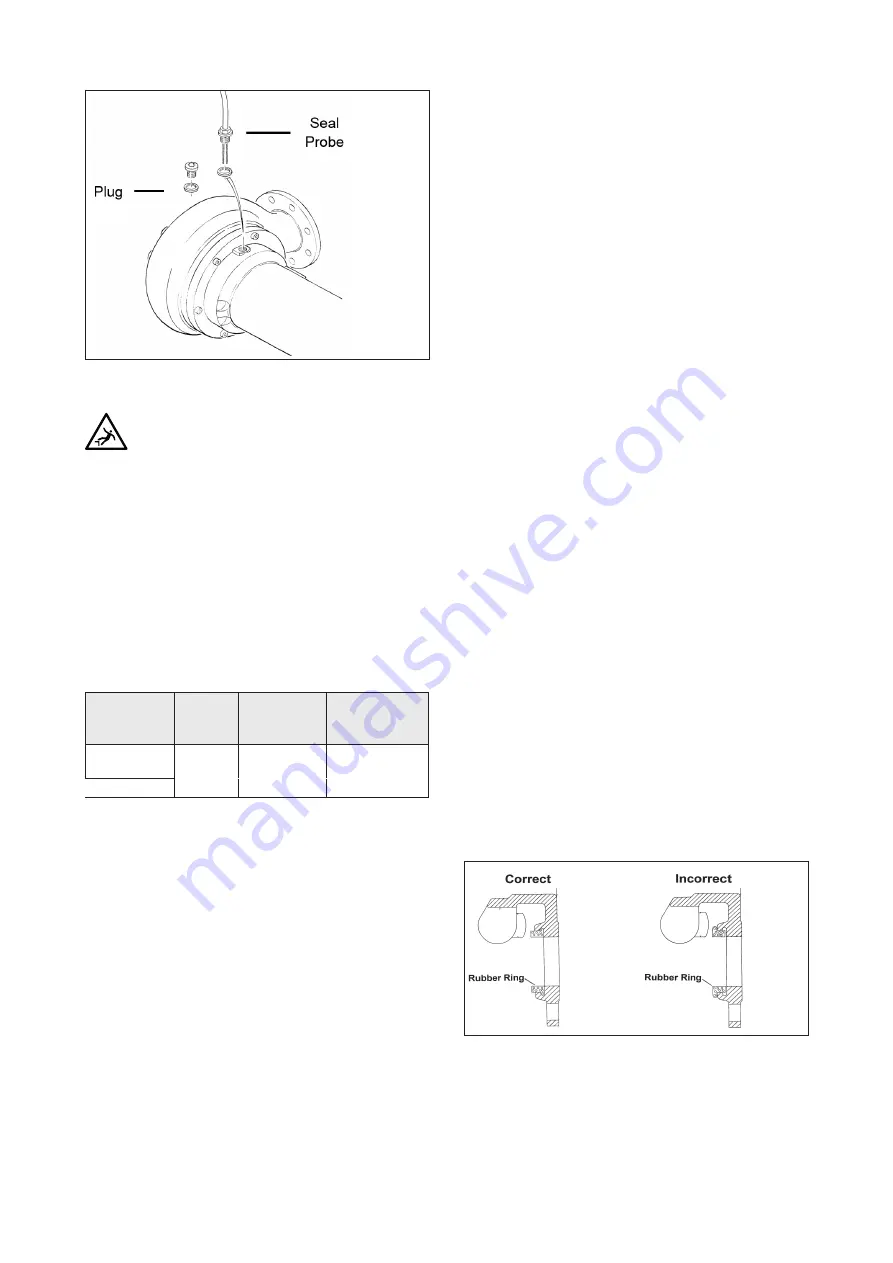

• Mount the guide claw on the pump discharge (thread

or flange connection). Ensure that the rubber profile

gasket is correctly seated in position in the guide claw

(as a seal against the coupling base), so that it will not

fall out when lowering the pump. See graphic below

• Attach the chain to the pump handle or lifting lugs.

Insert the pump with the guide rails in the guide claw

ears. Lower the pump into the wet well. If the pump

is seated on the base elbow, it automatically seals it-

self off to the pressure line and is ready for operation.

• Hang the end of the retrieval chain from a hook at the

wet well opening.

• Hang the motor connection cable of the pump in the

shaft at an appropriate length, with strain relief. Make

sure that the cables can not be bent or damaged.