12 | ENGLISH

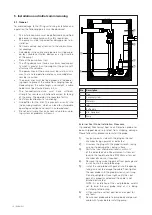

5.3. Use of chains

Chains are used to lower a pump in the operating space

or to pull it out. They are not intended to secure a floating

pump. Intended use is as follows:

• Fasten one end of the chain on the handle of the

pump provided for this purpose. If your pump has

two ring bolts as an attachment point, you must use

a double-strand chain. When doing so, the angle of

inclination of the chain strands must be between 0°

and 45°.

• Attach the other end to the lifting device.

• Ensure tension on the chain, and then lift the pump in

a slow and controlled manner.

• Gently lower the pump into operating space and low-

er it gently.

• Lower the pump to the operating point and make

sure that the pump has a secure footing or the cou-

pling system is engaged correctly.

• Remove the chain from the lifting device and secure it

to the safety chain, which is located at the top of the

operating room. This ensures that the chain can not

fall into the well and constitute a danger to anyone.

Please note the following diagrams during installation.

No.

Description

1

Chain guard

2

Chain

3

Handle

4

Pump

5.4. Initial operation

This chapter contains all the important instructions for op-

erating personnel for the safe commissioning and oper-

ation of the machine. The following information must be

strictly adhered to and checked:

• Type of installation

• Operating mode

• Minimum/max water coverage. Immersion depth

After a long downtime, these specifications are also

to be checked and any defects are to be rectified! The

operation and maintenance manual must always be

kept with the machine, or be kept in a designated place

where it is always accessible for all of the operating

personnel.

To avoid injury to persons or damage during operation of

the machine, the following points must be observed:

• The initial operation may only be carried out by qual-

ified and trained personnel accompanied by an au-

thorized HOMA representative following the safety

instructions.

• All staff working on the machine must receive, read,

and understand the instructions.

• Activate all safety devices and emergency stop

switches before initial operation.

• Electrical and mechanical adjustments may only be

performed by professionals.

• This machine is only suitable for use at the specified

operating conditions.

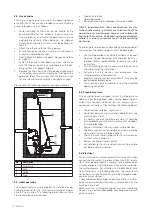

5.5. Preparatory work

This pump has been designed so that it will operate re-

liably and for long periods under normal operating con-

ditions. This requires, however, that you comply with all

advice and instructions. Please check the following points:

• Cable routing - no loops, slightly taut

• Liquid temperature and immersion depth check - see

machine data sheet

• If a hose is used on the discharge side, it should be

flushed before use with fresh water so that no depos-

its cause blockages

• For wet installation, the wet well must be cleaned

• The pressure and suction side pipe systems are to be

clean and all valves are to be opened.

• Check the accessories, pipe system and suspension

unit for firm and correct fit

• Review the present level control.

• An isolation test and a level control must be carried

out before commissioning.

5.6. Electrical

When installing and selecting electrical lines and when

connecting the motor, the relevant local and NEC regula-

tions must be observed. The motor must be protected by

a motor protection circuit breaker. Connect the motor per

the wiring diagram. Pay attention to the direction of rota-

tion! If rotation is in the wrong direction, the machine will

not perform to specifications,and can be damaged under

adverse circumstances.

Check the operating voltage, and ensure there is uniform

power consumption by all phases in accordance with the

machine data sheet.

Make sure that all temperature sensors and monitoring

devices, e.g. seal chamber probe, are connected and test-

ed for function.