ENGLISH | 17

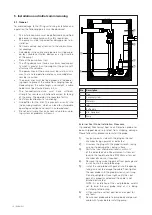

6.4. Sealing chamber

As there are several versions and designs of these mo-

tors, the exact location of the screw plugs varies depend-

ing on the pump unit used.

• Slowly and carefully remove the filling plug from the

seal room.

Caution: The oil may be pressurized!

• Remove the drain plug. Drain the oil and collect it in

a suitable reservoir. Clean the drain plug, fit with a

new sealing ring and screw it in again. For complete

drainage, the machine must be slightly tipped on to

its side.

Make sure that the pump is on its side and secure!

• Fill lubricant by means of the opening in the filling

plug. Comply with the specified lubricants and filling

quantities.

• Clean the filling plug, fit with a new sealing ring and

screw it in again.

7. Repairs

7.1. General

When carrying out repair work, the following information

should always be noted:

• Round sealing rings as well as existing seals should

always be replaced.

• Screw fixings such as spring washers should always

be replaced.

• The correct torques must be observed.

In general, the following applies to repairs:

Switch off the machine, disconnect it from the pow-

er supply (have this done by an electrician), clean it

and place it on a solid base in a horizontal position.

Secure it from falling over and/or slipping.

En général, les dispositions suivantes s‘appliquent

aux réparations :

Éteindre la machine, la débrancher du réseau élec-

trique (faire appel à un électricien), la nettoyer et la

placer sur une base solide en position horizontale.

Éviter qu‘elle ne tombe et/ou ne glisse.

If not otherwise stated, the torque values of the

below tables should be used. Values stated are for clean,

lubricated screws. Fixing torque [ft lbs] for screws A2/A4

(Coefficient of friction = 0.2)

A2/A4,

Hardeness class 70

A2/A4,

Hardeness class 80

DIN912/DIN933

DIN912/DIN933

M6

5 ft lbs

9 ft lbs

M8

12.5 ft lbs

21 ft lbs

M10

24 ft lbs

43 ft lbs

M12

42 ft lbs

73.5 ft lbs

M16

103 ft lbs

180.5 ft lbs

M20

201.5 ft lbs

364.5 ft lbs

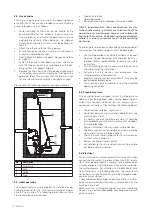

7.2. Changing the impeller and volute

Changing the impeller and the volute.

• Loosen and remove the screws holding the volute to

the oil chamber.

• Secure and remove the volute from the oil chamber

with suitable equipment, e.g. hoisting gear. Place on

a secure base.

• Fasten the impeller with suitable equipment, loosen

and remove the impeller fastening (cylindrical screw

with socket hex).

Pay attention to the locking screw!

• Remove the impeller from the shaft using a suitable

extractor.

• Clean the shaft

• Attach a new impeller to the shaft.

Make sure that the sliding surfaces do not become

damaged!

• Screw a new impeller bolt and clamping disk back

onto the shaft. Fasten the impeller and tighten the

impeller bolt. See table below for toque values.

• Place the motor assembly with impeller back onto

the volute and fasten it with screws.

• It must be possible to turn the impeller by hand.

Impeller Bolt Size

Torque

10mm

35 Nm / 26 ft lb

12mm

61 Nm / 45 ft lb

16mm

146 Nm / 108 ft lb

20mm

285 Nm / 210 ft lb

Changing wear ring

The stationary and rotating wear rings determine the gap

between the impeller (rotating wear ring) and the suction

port (stationary wear ring). If this gap is too big, the per-

formance of the machine decreases, and/or it can lead to

ragging or clogging. If the stationary ring shows signs of

wear, it should be replaced. This minimizes wear on the

suction port and and impeller, consequently reducing ex-

pense for spare parts.

Only OEM Parts may be used for replacement!