ENGLISH | 03

1.2. Preface

Dear Customer,

Thank you for choosing one of our company’s products.

You have purchased a product which has been manufac-

tured to the latest technical standards. Read this operat-

ing and maintenance manual carefully before first use in

order to ensure that the product is used safely.

The documentation contains all the necessary specifica-

tions for the product, allowing you to use it properly. In

addition, you will also find information on how to recog-

nize potential dangers, reduce repair costs and downtime,

and increase the reliability and working life of the product.

All safety requirements and specific manufacturer’s re-

quirements must be fulfilled before the product is put into

operation. This operating and maintenance manual supple-

ments any existing national regulations on industrial safety

and accident prevention. This manual must also be acces-

sible to personnel at all times and also be made available

where the product is used.

1.3. Proper use

In the event of improper use, there is a danger to life for

the user as well as for third parties. Additionally, the prod-

uct and/or attachments may be damaged or destroyed. It

is important to ensure that the product is only operated

in good condition and as intended. To do so, follow the

operating instructions.

The pumps can be used in the range specified by the man-

ufacturer, in accordance with the current HOP.SEL version.

Please note that the offered pumps may only be used in

the defined field of application. Operating the pump out-

side the application range can lead to operational prob-

lems or significant damage to the unit.

1.4. Copyright

This operation and maintenance manual has been copy-

righted by the manufacturer. This operation and mainte-

nance handbook is intended for use by assembly, oper-

ating and maintenance personnel. It contains technical

specifications and diagrams which may not be reproduced

or distributed, either completely or in part, or used for any

other purpose without the expressed consent of the man-

ufacturer.

1.5. Technical terms

Various technical terms are used in this operating and

maintenance manual.

Dry run

The product is running at full speed, however, there is no

liquid to be pumped. A dry run is to be strictly avoided. If

necessary, a safety device must be installed.

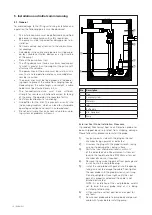

“wet” installation type

This installation type requires the product to be immersed

in the pumped fluid. It is completely surrounded by the

pumped fluid. Please observe the values for the maximum

submersion depth and the minimum water coverage.

“dry” installation type

In this installation type, the product is installed dry, i.e. the

pumped fluid is delivered to and discharged via a pipeline

system. The product is not immersed in the pumped fluid.

Please note that the surfaces of the product become very

hot!

“transportable” installation type

With this installation type the product is equipped with a

pedestal. It can be installed and operated at any location.

Please observe the values for the maximum submersion

depth and the minimum water coverage, and remember

that the surfaces of the product become very hot.

“S1” operating mode (continuous operation)

At the rated load, a constant temperature is reached that

does not increase even in prolonged operation. The oper-

ating equipment can operate uninterruptedly at the rated

load without exceeding the maximum permissible tem-

perature.

Operating mode “S3” (intermittent operation):

For this operating mode, after the abbreviation, the per-

cent duty cycle is displayed, as well as the cycle duration if

it is greater than 10 minutes. For example S3 40% means

the pump can operate continuously for 40% (24 minutes)

of one hour, and must then pause for 36 minutes.

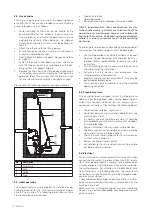

Low Level Lockout

The low level lockout is designed to automatically shut

down the product if the water level falls below the min-

imum water coverage value of the product. This is made

possible by installing a float switch.

Level control

The level control is designed to switch the product on or

off depending on the water level. This is made possible by

installing a float switch.