Summary of Contents for HBG 2.0

Page 1: ...1 HB2 OM 050221 2021 HOMEBIOGAS VERSION 050221 HBG 2 0 HOUSEHOLD BIOGAS SYSTEM OWNER S MANUAL ...

Page 13: ...13 i ii iii x4 parts bag 1 i i ii iii LUBRICANT LUBRICANT ...

Page 15: ...15 1 parts bag LUBRICANT LUBRICANT ...

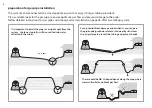

Page 16: ...16 x2 Inlet sink orientation short cord plunger slot towards back long cord towards front ...

Page 19: ...19 check filled digester for leaks contact HomeBiogas if any leaks are seen ...

Page 20: ...20 ii i LUBRICANT x2 ...

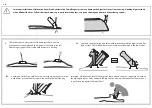

Page 21: ...21 i ii iii v iv 90 ...

Page 22: ...22 x40 i ii iii use dry sand only sand bags ...

Page 23: ...23 2 top x16 left right x16 back front x8 1 2 3 x2 x8 x8 x2 x2 x2 x2 x2 x2 x2 x2 x2 x2 x2 ...

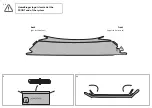

Page 24: ...24 iii ii GAS FILTER i remove 2 protective stickers from cover base of gas filter ...

Page 29: ...29 ...

Page 37: ...37 ...

Page 43: ...43 ...

Page 47: ...47 ...