40

troubleshooting

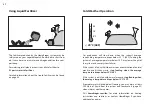

No gas at the burner, and the gas tank is empty

1. Gas valve was left open.

Check if system gas valve, drainage connector or stove’s gas valve

have been left open, allowing the gas to escape. ensure stove is

turned off, gas valve is closed and drainage connector is screwed

shut.

2. System has not been fed for some time.

Feed the system.

3. Water level in the digester tank has fallen too low allowing gas

to escape through sink.

Fill the digester tank with water until you see liquid pouring out of

Fertilizer Outlet.

4. Cold weather caused bacteria to stop gas production.

Reduce feeding volumes (refer to cold weather operations on page

34) or wait for the weather to warm up.

5. There is a gas leak somewhere in the system or along the gas

tubes.

To locate leak, apply soapy water along the gas pipes, tank flanges

and pipe joints. Leakage will cause bubbles to appear. Fix the leak

or replace the leaky element.

6. pH level in the system is abnormally low (<5.0), causing gas

production to stop (see page 41 for details on pH checking).

Contact HomeBiogas for assistance.

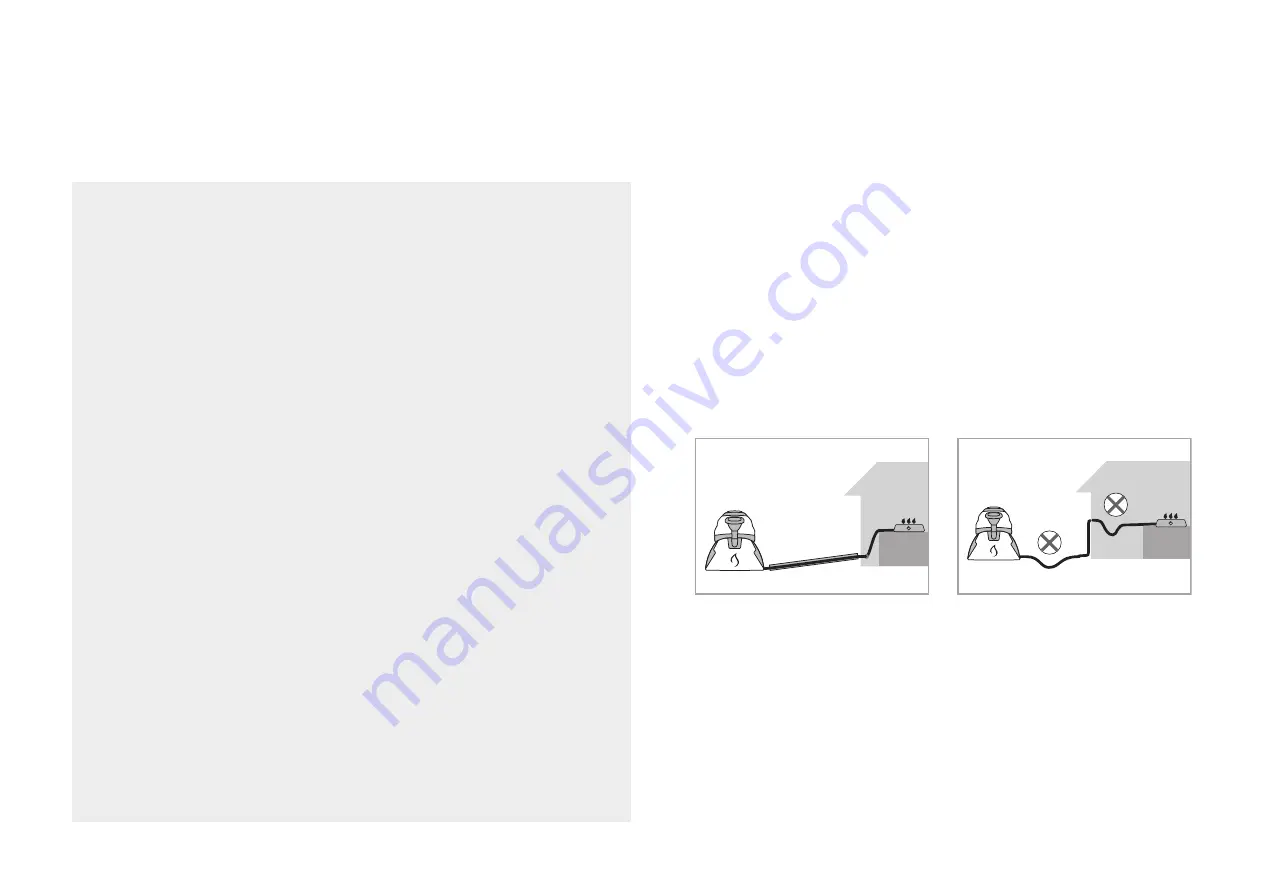

The most likely cause is accumulation of water condensation in the

gas pipe, blocking the free flow of gas to the stove.

Ensure there are no bends/dips in the pipe from stove to system that

water can collect in. The gas pipe should also be installed at a slight

angle from the system to the stove.

Gas tank is filled but there is no gas flow, or

flame sputters and dies frequently

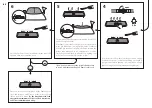

1. Drain collected water from the gas pipes.

i. Open the water drainage valve and drain any collected

condensation from the gas tube (refer p38).

ii. If problem persists, you may need to empty the 10mm gas tube

separately - open clamps, disconnect the 10mm gas tube from

the reducer fitting and stove and drain out any water from the

tube. Blowing through the tube or using an electric air pump to

pass air through the tube will help to clear out collected water.

iii. Close drainage connector and reopen gas valve.

Summary of Contents for HBG 4.0

Page 1: ...1 HB4 OM 150221 VERSION 150221 HBG 4 0 HOUSEHOLD BIOGAS SYSTEM OWNER S MANUAL 2021 HOMEBIOGAS...

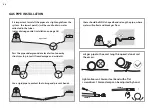

Page 13: ...13 i i ii ii iii i iii x4 parts bag 1 LUBRICANT LUBRICANT...

Page 15: ...15 i LUBRICANT 1 parts bag LUBRICANT...

Page 16: ...16 Inlet sink orientation short cord plunger slot towards back long cord towards front x2...

Page 19: ...19 check filled digester for leaks contact HomeBiogas if any leaks are seen...

Page 20: ...20 ii i LUBRICANT x2...

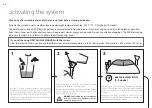

Page 21: ...21 i ii iii v iv 90...

Page 22: ...22 x48 i ii iii use dry sand only sand bags...

Page 23: ...23 x5 x5 x5 x5 x3 x3 x3 x3 x3 x3 x3 x3 x1 x1 x1 x1...

Page 24: ...24 iii ii i GAS FILTER remove 2 protective stickers from cover base of gas filter...

Page 29: ...29...

Page 43: ...43...

Page 47: ...47...