1

7

A

B

1

2

3

A1

4

A2

1

2

3

B1

1

2

B2

B5

1

3

3

2

2

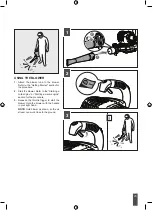

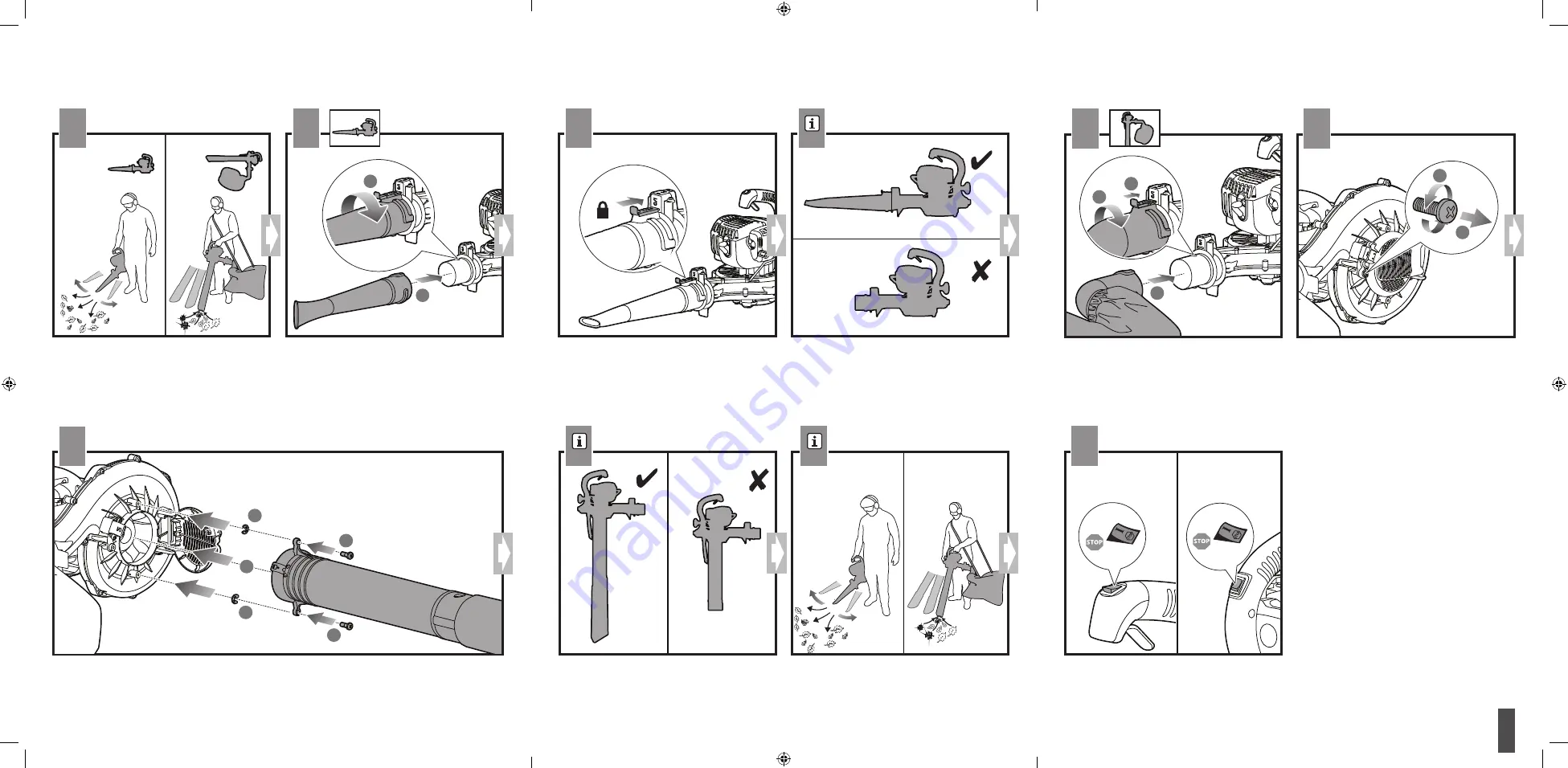

1.

Align raised tabs on upper blower tube with the slots on

blower housing outlet.

2.

Attach and tighten securely by

turning clockwise until it clicks into place.

A.

Attach the blower tube.

B.

Attach the vacuum tubes.

Press slider plate into positive switch’s slot.

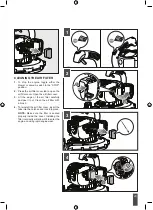

1.

Align the raised slots on the vacuum bag adaptor with

the raised locking tabs on the blower housing outlet; push

the bag adaptor onto the housing.

2.

Twist to lock into

place.

3.

Press the slider plate into the positive switch slot

to make sure the switch is engaged and ready to operate.

1.

Depress door tab using a flat head screwdriver.

2.

Loosen the screw on the door to open vacuum inlet door.

1.

Align tabs on housing with the vacuum tube assembly.

2.

Tighten screws on upper vacuum tube to secure to blower

housing.

A.

Hold the blower with the upper handle in your right hand.

Place the vacuum bag strap over your right shoulder. Hold

the upper handle in your left hand and the vacuum handle

in your right hand.

To stop the engine, toggle either the blower or vacuum

switch to the “STOP” position.

NOTE:

Ensure to attach the blower tube securely to the

blower/vacuum housing.

NOTE:

Ensure to attach the vacuum tubes securely to the

blower/vacuum housing.

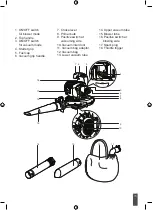

Summary of Contents for HBL26BVB

Page 1: ...HBL26BVB ...

Page 15: ...Original instructions English 13 ...

Page 16: ...14 x 1 x 1 x 1 x 1 x 1 x 1 x 1 ...

Page 20: ...18 ...

Page 21: ...19 Cold start engine Warm start engine Using the blower Using the vacuum p 21 p 25 p 23 p 26 ...

Page 37: ......

Page 38: ......

Page 39: ......