Page 29

Fig. 66

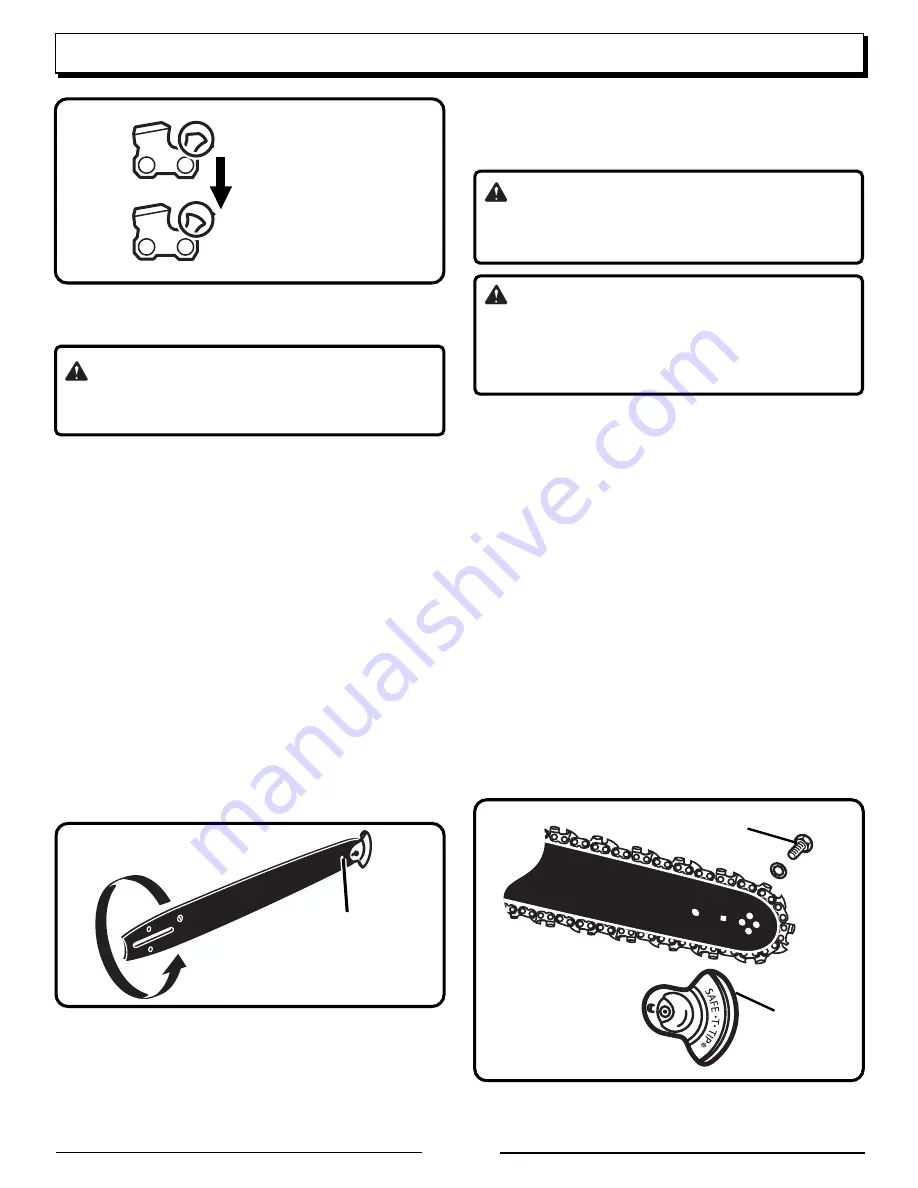

MAINTAINING THE GUIDE BAR

See Figure 67.

CAUTION:

Make sure the chain has stopped before you do any

work on the saw.

Every week of use, reverse the guide bar on the saw to

distribute the wear for maximum bar life.

The bar should be cleaned every day of use and checked

for wear and damage.

Feathering or burring of the bar rails is a normal process

of bar wear. Such faults should be smoothed with a file as

soon as they occur.

A bar with any of the following faults should be replaced:

■

Wear inside the bar rails that permits the chain to lay

over sideways

■

Bent guide bar

■

Cracked or broken rails

■

Spread rails

In addition, lubricate guide bars (with a sprocket at their

tip) weekly. Using a grease syringe, lubricate weekly in the

lubricating hole.

Turn the guide bar and check that the lubrication holes and

chain groove are free from impurities.

MAINTAINING THE SAFE-T-TIP

®

NOSE

GUARD

See Figures 68 and 69.

CAUTION:

Make sure the chain has stopped before you do any

work on the saw.

WARNING:

Although the guide bar comes with a SAFE-T-TIP

®

anti-kickback device already installed, you need to

check the tightness of the mounting screw before each

use.

Tighten the mounting screw of the nose guard as in-

structed below. These are specially hardened screws. If

you cannot install the screw tightly, replace both the screw

and the SAFE-T-TIP

®

, before further operation.

Note:

Do not replace the screw with an ordinary screw;

manufacturer's replacement parts should be used when

replacing parts.

In addition to preventing chain contact with solid objects

at the nose of the bar, the SAFE-T-TIP

®

also helps keep

the chain away from abrasive surfaces, such as the

ground. Keep it on the right hand side of the bar where it

will be between the chain and the ground during flush with

ground cutting.

The mounting screw requires a 5/16 in. wrench (or

adjustable wrench) to achieve the recommended tight-

ness of 35 to 45 in. lb. (4-5 Nm). A tightness within this

range can be achieved by using the following method.

1.

Tighten the screw to a finger tight position.

2.

Tighten the screw an additional 3/4 of a turn using a

wrench.

MAINTENANCE

Fig. 67

LUBRICATING HOLE

MOUNTING

SCREW

SAFE-T-TIP

®

Fig. 68

RESTORE ORIGINAL

SHAPE BY ROUNDING

THE FRONT