12/19

ALFA IN a.s.

©

www.alfain.eu

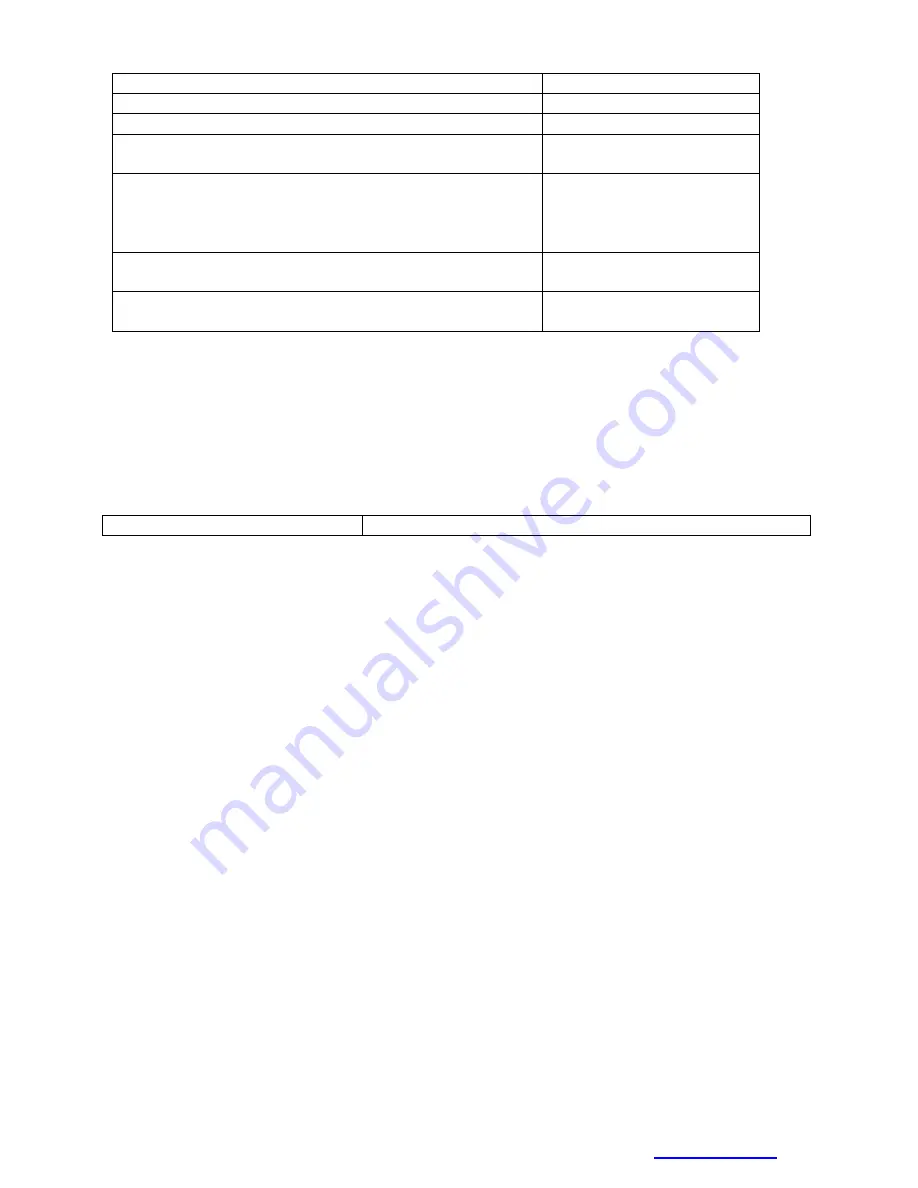

Checking the oil level

daily or before every start

Check air filter

1

daily or before every start

Control of air sampling openings and cooling surfaces

1

daily or before every start

Cleaning foam air filter

Every 3 months

or 50 hours.

Changing the oil

First: month or 20 hours of

operation.

After that: every 6 months

or 100 hours of operation.

Check the wear of the spark plugs and cable

every 100 hours of

operation

General inspection of equipment

2

every year or every 300

hours of operation

1

Periods shorten up to ½ when the equipment is operated in extremely dusty

or dirty environments

2

Let make an authorized service partner

Check oil level / top up oil

Oil

10W 40 (-

18°C - 50°C), 5W 40(-40°C - 0°C)

1. Make sure, that the device has not running, the starter position is

OFF, it is in a horizontal position and is chilly, allow the oil to drain into

the oil pan.

2. Clean the area around the oil cap throat to prevent possible oil

contamination when opening the oil cap throat.

3. Remove the oil cap stopper

4. The oil level should be up to the upper edge of the throat, but it would

not leak.

5. In the event that the oil level does not reach the upper edge of the

throat. Top up oil (by oil throat) so that the oil level reached to the

upper edge of the throat.

Checking maintenance and replacement of the air filter and air

system

Daily or before starting, check the air filter. Check the dirt and debris around

the air cleaner. Keep this area clean. Also check for loose or damaged.

Replace all bent or damaged air cleaner components.

NOTE:

Operating the engine with loose or damaged air cleaner components

could allow unfiltered air into the engine causing premature wear or damage.