11

HOT

RESTART

If the engine is operated at higher ambient temperatures, then turned off and allowed to sit for a short

time, it may not restart on the first pull.

5.2

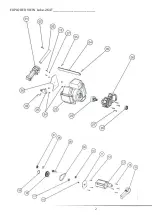

SETTING THE OPERATING MODE 2-26 (LOKE-26 4T) (FIG. 3)

The operating mode of the drill is selected with the mode selector switch

11

. To change the operating

mode push the release button

10

and turn the mode selector switch

11

to the requested position until it

can be heard to latch

NOTE: Change the operating mode only when the machine is switched off!! Otherwise the machine can

be damaged.

5.3

SETTING THE OPERATING MODE 5-40 (BALDER-36 4T) (FIG. 4)

The operating mode of the drill is selected with the mode selector switch

3.

Turn the mode selector switch

3

to the requested position.

NOTE: Change the operating mode only when the machine is switched off!! Otherwise the machine can

be damaged.

5.4

REMOVING/INSERTING THE QUICK CHANGE CHUCK 2-26 (LOKE-26 4T) (FIG. 3)

Pull the lock ring for the quick change chuck

6

toward the rear, hold it in position and pull off the quick

change chuck.

After removing, protect the chuck against contamination.

INSERTING

THE

QUICK

CHANGE

CHUCK

Before inserting clean the quick change chuck and apply a light coat of grease to the shank end.

Grasp the SDS-plus quick change chuck

2

or the quick change keyless chuck

1

completely with your hand

.

Slide the quick change chuck with a turning motion onto the drill chuck mounting, until a distinct latching

noise is heard. The quick change chuck is automatically locked. Check the locking effect by polling the

quick change chuck.

5.5

CHANGING THE TOOL SDS-PLUS LOKE-26 4T (FIG. 3)

The dust protection cap

4

largely prevents the entry of drilling dust into the tool holder during operation.

When inserting the tool, take care that the dust protection cap

4

is not damaged.

INSERTING

SDS-

PLUS

DRILLING

TOOL:

The SDS-plus drill chuck allows for simple and convenient changing of drilling tool without the use of

additional tools. Clean and lightly grease the shank end of the tool. Insert the tool in a twisting manner

into the tool holder until it latches itself.

REMOVING

SDS-

PLUS

DRILLING

TOOL

Push back the docking sleeve

5

and remove the tool.

5.6

CHANGING THE TOOL SDS-MAX BALDER-36 4T (FIG. 4)

The dust protection cap

1

largely prevents the entry of drilling dust into the tool holder during operation.

When inserting the tool, take care that the dust protection cap

1

is not damaged.

INSERTING

SDS-

MAX

DRILLING

TOOL:

The SDS-max drill chuck allows for simple and convenient changing of drilling tool without the use of

additional tools. Clean and lightly grease the shank end of the tool. The red symbols (open lock and bars)

on the locking sleeve

2

indicate that the tool holder is open.