13

6.3

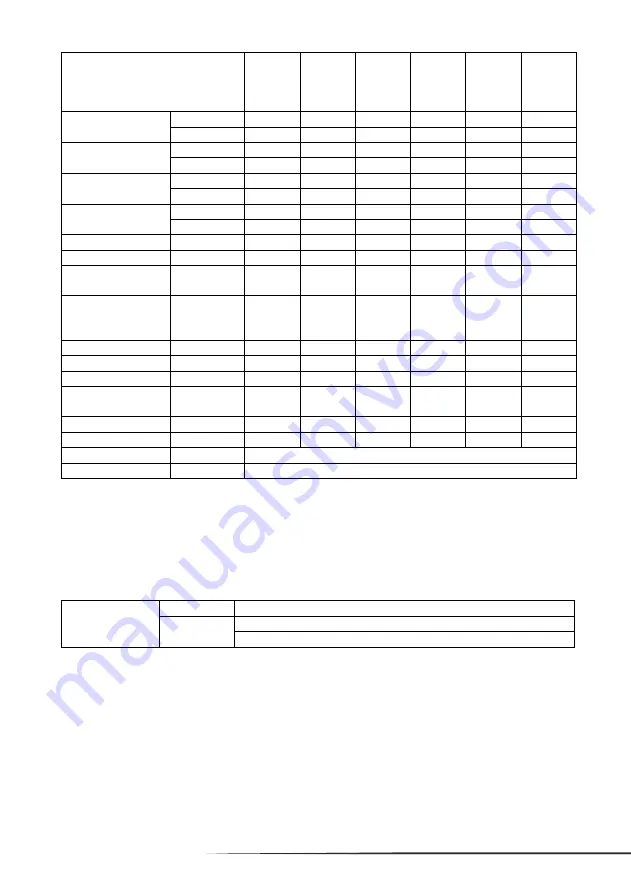

MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD

: Perform

at every indicated month or

operating hour interval, whichever

comes first

Each

use

First

month

or 10

hrs

Every 3

months

or 25

hrs

Every 6

months

or 50

hrs

Every

year

or 100

hrs

Every 2

years

or 300

hrs

Engine oil

Check level

•

Change

•

•

Air cleaner

Check

•

Clean

•(1)

Spark plug

Check-adjust

•

Replace

•

Timing belt

Check

•

Clean

•

Spark arrester

Clean

•

Exhaust filter

Clean

•

Engine cooling fins

Check

•

Nuts, bolts, fasteners

(retighten if

necessary)

Check

•

Clutch shoes

Check

•(2)

Idle speed

Check-adjust

•(2)

Valve clearance

Check-adjust

•(2)

Combustion chamber Clean

•(2)

Fuel filter

Check

•

Fuel tank

Clean

•

Fuel tubes

Check

Every 2 years (replace if necessary)(2)

Oil tube

Check

Every 2 years (replace if necessary)(2)

(1)

Service more frequently when used in dusty areas.

(2)

This items should be serviced by your servicing dealer, unless you have the proper tools and are

mechanically proficient.

Failure to follow this maintenance schedule could result in non-warrantable failures.

6.4

REFUELING

Unleaded

gasoline

U.S.A.

Pump octane rating 86 or higher

Except

U.S.A.

Research octane rating 91 or higher

Pump octane rating 86 or higher

This engine is certified to operate on unleaded petrol with a pump octane rating of 86 or higher (a

research octane rating of 91 or higher).

Refuel in a well-ventilated area with the engine stopped. If the engine has been running, allow it to cool

first. Never refuel the engine inside a building where petrol fumes may reach flames or sparks.

You may use regular unloaded petrol containing no more than 10% Ethanol (E10) or 5% Methanol by

volume. In addition, Methanol must contain solvents and corrosion inhibitors. Use of fuels with content of

Ethanol or Methanol greater than shown above may cause starting and/or performance problems. It may

also damage metal, rubber and plastic parts of the fuel system. Engine damage or performance problems

that result from using a fuel with percentages of Ethanol and Methanol greater than shown above are not

covered under warranty.