GENERAL INFORMATION

1-10

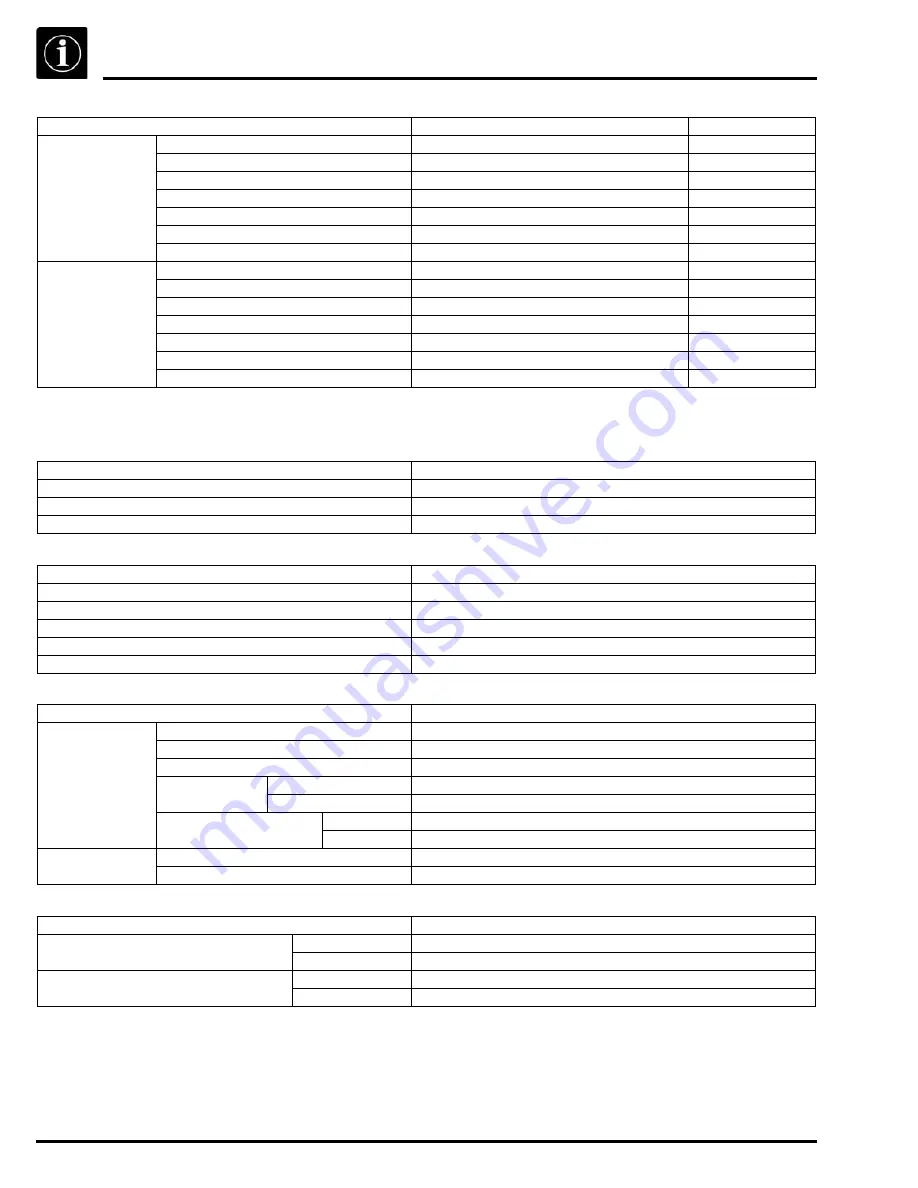

BRAKE SYSTEM

Unit: mm

ELECTRICAL SYSTEM SPECIFICATIONS

PGM-FI SYSTEM

IGNITION SYSTEM

BATTERY/CHARGING SYSTEM

LIGHTS/METERS/SWITCHES

ITEM

STANDARD

LIMIT

Front

Specified brake fluid

DOT 3 or DOT 4

–

Brake disc thickness

3.8 – 4.2

3.5

Brake disc warpage

–

0.3

Master cylinder I.D.

12.700 – 12.743

–

Master piston O.D.

12.657 – 12.684

–

Caliper cylinder I.D.

25.400 – 25.450

–

Caliper piston O.D.

25.318 – 25.368

–

Rear

Specified brake fluid

DOT 3 or DOT 4

–

Brake disc thickness

4.8 – 5.2

4.5

Brake disc warpage

–

0.3

Master cylinder I.D.

12.700 – 12.743

–

Master piston O.D.

12.657 – 12.684

–

Caliper cylinder I.D.

32.030 – 32.080

–

Caliper piston O.D.

31.948 – 31.998

–

ITEM

SPECIFICATIONS

EOT sensor resistance (20°C)

2.5 – 2.8 k

Ω

Fuel injector resistance (24°C)

11 – 13

Ω

EVAP purge control solenoid valve resistance (20°C)

37 – 44

Ω

ITEM

SPECIFICATION

Spark plug

CPR8EA-9 (NGK)

Spark plug gap

0.80 – 0.90 mm

Ignition coil peak voltage

100 V minimum

CKP sensor peak voltage

0.7 V minimum

Ignition timing ("F" mark)

8° BTDC at idle

ITEM

SPECIFICATIONS

Battery

Type

YTX7L-BS

Capacity

12 V – 6 Ah (10HR)/6.3 Ah (20HR)

Current leakage

0.25 mA maximum

Voltage

(20°C)

Fully charged

12.8 V minimum

Needs charging

Below 12.3 V

Charging current

Normal

0.6 A/5 – 10 h

Quick

3 A/1 h

Alternator

Capacity

0.168 kW/5,000 rpm

Charging coil resistance (20°C)

0.5 – 1.5

Ω

ITEM

SPECIFICATION

Fuse

Main

20 A

Sub

5 A x 1, 10 A x 2

Fuel level sensor resistance

(20°C)

Full

6 – 10

Ω

Empty

90 – 100

Ω

Summary of Contents for CBF190WH 2016

Page 19: ...GENERAL INFORMATION 1 18 NEUTRAL SWITCH WIRE CKP SENSOR WIRE ALTERNATOR WIRE ...

Page 25: ...MEMO ...

Page 31: ...FUEL ENGINE 2 6 FUEL TANK Quick connect fitting fuel pump side 2 2 ...

Page 36: ...FUEL ENGINE 2 11 INJECTOR EVAP SYSTEM Quick connect fitting injector side 2 2 Side cover 3 4 ...

Page 37: ...FUEL ENGINE 2 12 Fuel tank shroud 3 6 ...

Page 41: ...FUEL ENGINE 2 16 CYLINDER HEAD COVER Fuel tank shroud 3 6 ...

Page 47: ...FUEL ENGINE 2 22 CLUTCH GEARSHIFT LINKAGE Engine oil 2 14 0 5 1 0 mm ...

Page 57: ...MEMO ...

Page 60: ...FRAME CHASSIS 3 3 REARVIEW MIRROR SEAT 34 N m 34 N m ...

Page 61: ...FRAME CHASSIS 3 4 SIDE COVER PILLION STEP ...

Page 62: ...FRAME CHASSIS 3 5 REAR COWL 1 0 N m Seat 3 3 Side cover 3 4 Pillion step 3 4 1 0 N m ...

Page 63: ...FRAME CHASSIS 3 6 FUEL TANK SHROUD Rear cowl 3 5 1 0 N m ...

Page 64: ...FRAME CHASSIS 3 7 FUEL TANK CENTER COVER FRONT VISOR Fuel tank shroud 3 6 Speedometer 4 34 ...

Page 65: ...FRAME CHASSIS 3 8 FRONT FENDER Except CL type CL type Front wheel 3 16 Front wheel 3 16 ...

Page 66: ...FRAME CHASSIS 3 9 DRIVE SPROCKET COVER Left side cover 3 4 ...

Page 68: ...FRAME CHASSIS 3 11 REAR FENDER B DRIVE CHAIN COVER Rear fender A 3 10 ...

Page 70: ...FRAME CHASSIS 3 13 BRAKE PEDAL GEARSHIFT PEDAL Step holder 3 12 ...

Page 71: ...FRAME CHASSIS 3 14 CENTERSTAND SIDESTAND Muffler cover 3 15 39 N m 10 N m ...

Page 72: ...FRAME CHASSIS 3 15 EXHAUST PIPE MUFFLER 26 N m 10 N m 20 5 22 5 mm 11 N m ...

Page 73: ...FRAME CHASSIS 3 16 FRONT WHEEL 64 N m 23 N m ...

Page 78: ...FRAME CHASSIS 3 21 STEERING STEM TOP BRIDGE 74 N m 23 N m Handlebar 3 20 Front visor 3 7 ...

Page 80: ...FRAME CHASSIS 3 23 REAR WHEEL 88 N m Wheel inspection ...

Page 89: ...MEMO ...

Page 114: ...ELECTRICAL SYSTEM 4 25 STARTER MOTOR Electric starter inspection ...

Page 115: ...ELECTRICAL SYSTEM 4 26 NEUTRAL SWITCH Drive sprocket cover 3 9 Engine oil 2 14 ...

Page 118: ...ELECTRICAL SYSTEM 4 29 Rear fender A 3 10 19 N m Front Front visor 3 7 Rear Seat 3 3 ...

Page 119: ...ELECTRICAL SYSTEM 4 30 HEADLIGHT AIM 1 0 N m Seat 3 3 Beam up Beam down ...