36

Servicing Your Honda

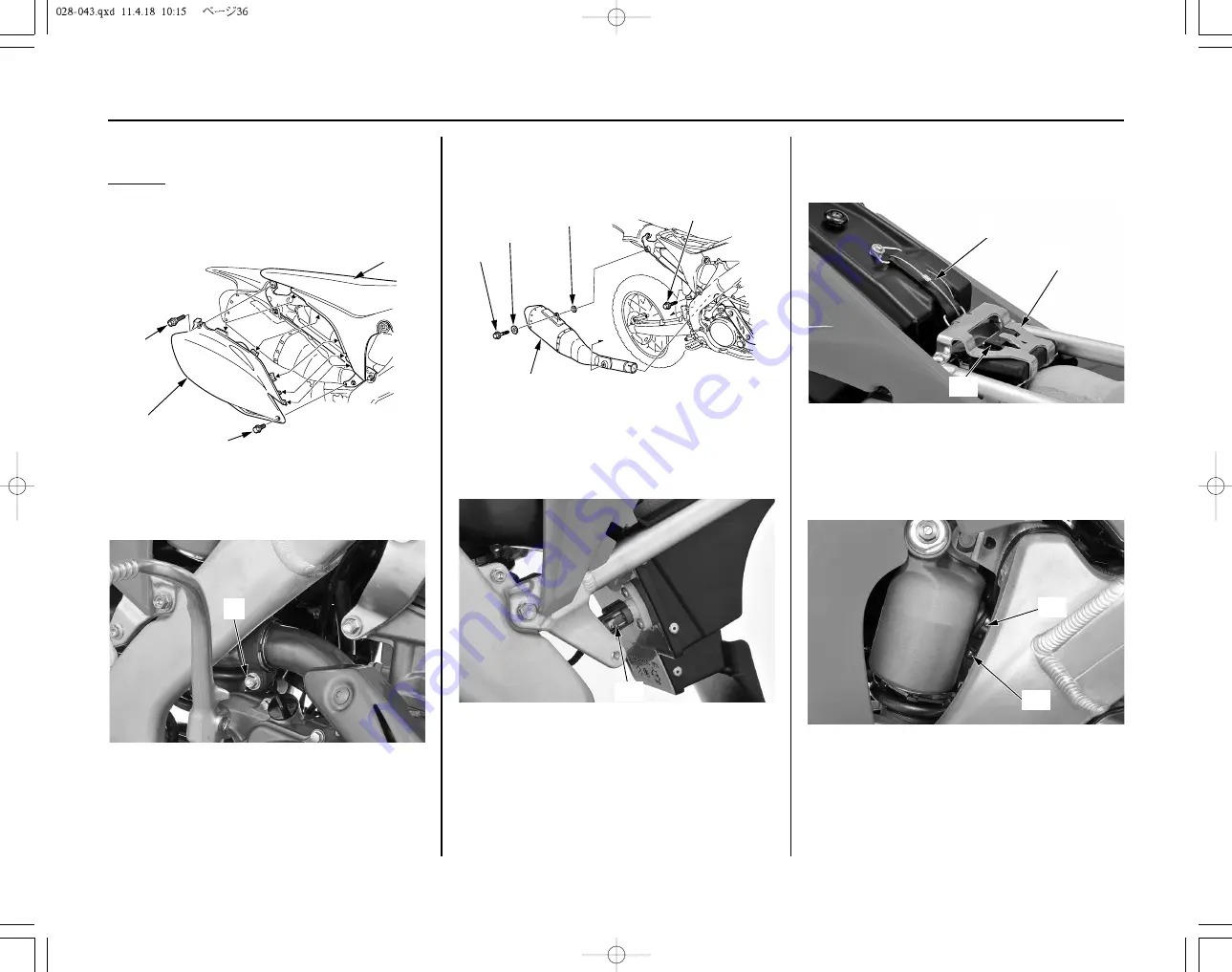

Subframe

Refer to Safety Precautions on page 23.

Removal

1. Remove the side covers (1) by removing the

seat mounting bolts (2) and bolts (3).

2. Remove the seat (4).

(1) side covers

(3) bolts

(2) seat mounting bolts

(4) seat

3. Loosen the muffler clamp bolt (5).

(3)

(4)

(2)

(1)

(5) muffler clamp bolt

(5)

(15)

(16)

4. Remove the muffler mounting A bolt (6),

muffler mounting B bolt (7), washer A (8),

washer B (9) and muffler (10).

(6) muffler mounting A bolt

(9) washer B

(7) muffler mounting B bolt

(10) muffler

(8) washer A

5. Disconnect the IAT sensor connector (11).

6. Remove the ECM mounting rubber (12) from

the ECM bracket (13).

Unhook the fuel tank band (14).

(12) ECM mounting rubber

(13) ECM bracket

(14) fuel tank band

7. Loosen the screw (15) on the air cleaner

connecting tube clamp (16).

(15) screw

(16) air cleaner connecting tube clamp

(6)

(7)

(8)

(9)

(10)

(12)

(14)

(13)

(11) IAT sensor connector

(11)

Summary of Contents for crf250r 2012

Page 1: ......

Page 2: ...2012 Honda CRF250R OWNER S MANUAL COMPETITION HANDBOOK ...

Page 7: ......

Page 17: ...10 Instruments Controls ...

Page 21: ...14 Before Riding ...

Page 27: ...20 Basic Operating Instructions ...

Page 147: ...140 Adjustments for Competition ...

Page 165: ...158 Technical Information Wiring Diagram ...

Page 174: ...MEMO ...

Page 175: ...MEMO ...

Page 176: ...MEMO ...