Summary of Contents for EM500

Page 2: ......

Page 7: ...CARRYING HANDLE FUEL TANK CAP THROTTL GROUND AIR CLEANER COVER 3 ...

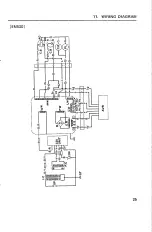

Page 29: ...I C mr B Y B Y r P I I I E kY I I AVR I ...

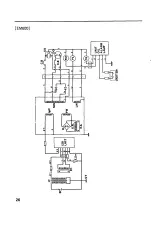

Page 30: ... EM6001 0 u 26 ...

Page 32: ...MEMO 28 ...

Page 35: ...MEMO 30 ...

Page 36: ......

Page 37: ......