Summary of Contents for EZ6500CXS

Page 1: ......

Page 10: ...L LB Type AC EXTERNAL CHARACTERISTIC CURVES S SB Type AC EXTERNAL CHARACTERISTIC CURVES 10 ...

Page 11: ...LS Type AC EXTERNAL CHARACTERISTIC CURVES 11 ...

Page 44: ...4 4 ALTERNATING CURRENT VOLTAGE IS OV 44 ...

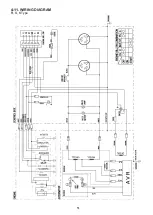

Page 51: ...4 11 WIRING DIAGRAM R S K Type 51 ...

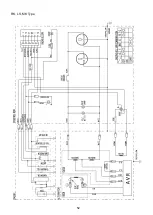

Page 52: ...RK LS MK Type 52 ...

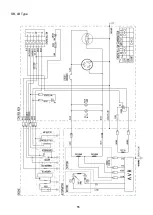

Page 53: ...REH CL Type 53 ...

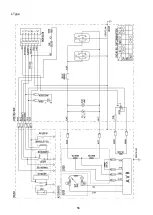

Page 54: ...M Type 54 ...

Page 55: ...SB LB Type 55 ...

Page 56: ...L Type 56 ...

Page 57: ...62EAB00 2019 Sep ...